The Global Demand for Custom Furniture: A Challenge for Mass Producers. This increasing desire for personalized furniture presents a significant hurdle for companies accustomed to mass production. The market for bespoke pieces is booming, demanding unique designs and tailored solutions that often clash with traditional manufacturing models. This shift requires a strategic response from mass producers to adapt, innovate, and retain market share in this evolving landscape.

The article delves into the intricacies of this evolving market, examining the characteristics of custom furniture, the challenges it poses to mass producers, and the innovative strategies for adapting to this change. It explores the role of technology in streamlining the process and offers a glimpse into the future of the industry.

Understanding the Custom Furniture Market

The custom furniture market represents a significant departure from the mass-produced furniture industry. It caters to the unique needs and preferences of individual clients, fostering a personalized approach that contrasts sharply with the standardized designs of mass-produced pieces. This focus on bespoke solutions drives a different set of dynamics and considerations.The increasing demand for custom furniture is a reflection of evolving consumer desires.

Clients increasingly seek furniture that aligns perfectly with their specific spaces and lifestyle requirements, and this personalization translates into a greater emphasis on design, quality, and durability. This desire for individuality, coupled with the growing awareness of sustainability and ethically sourced materials, has spurred the growth of this segment.

Characteristics of the Custom Furniture Market

The custom furniture market is characterized by a high degree of customization. Unlike mass-produced furniture, custom pieces are designed and crafted to meet specific dimensions, materials, and aesthetic preferences. This personalized approach often involves close collaboration between the client and the designer or craftsman, ensuring a tailored final product. Materials used in custom furniture can vary significantly, from premium woods and exotic veneers to innovative and sustainable alternatives.

Factors Driving Demand

Several factors contribute to the rising demand for custom furniture. A key driver is the desire for unique and personalized pieces. Consumers are increasingly seeking furniture that reflects their individual style and complements their specific interior design. Furthermore, the availability of advanced design software and manufacturing techniques allows for more intricate and bespoke designs. Finally, the rising awareness of sustainability and ethical sourcing of materials also plays a role, as custom furniture often allows for the use of locally sourced and eco-friendly materials.

Types of Custom Furniture

Custom furniture encompasses a broad range of options. Custom cabinetry, for instance, allows for tailored storage solutions that maximize space efficiency. Bespoke upholstery pieces offer the opportunity to create unique seating arrangements and incorporate desired textures and colors. One can also create custom home offices, incorporating ergonomic elements and unique storage features. These tailored solutions go beyond basic functionality and create aesthetically pleasing and practical solutions.

Comparison of Custom and Mass-Produced Furniture

| Feature | Custom Furniture | Mass-Produced Furniture |

|---|---|---|

| Design | Highly personalized, tailored to specific needs | Standardized designs, often limited variety |

| Materials | Wide range of options, including premium and sustainable materials | Often limited to readily available materials |

| Dimensions | Precisely tailored to the client’s space | Limited sizes and configurations |

| Cost | Generally higher due to the personalized nature of the piece | Lower cost due to mass production |

| Lead Time | Longer lead time due to the bespoke nature of the piece | Shorter lead time due to the standardized nature of the piece |

| Sustainability | Potentially higher emphasis on sustainability | Varying levels of sustainability, often depending on the manufacturer |

This table highlights the key distinctions between custom and mass-produced furniture, illustrating the trade-offs involved in choosing each option. It’s important to note that while custom furniture comes with a higher price tag and longer lead times, it often offers a greater sense of uniqueness and satisfaction, particularly for individuals with distinct design preferences or specific spatial requirements.

Challenges for Mass Producers

Source: ourcraftymom.com

The surge in demand for custom furniture presents a significant hurdle for mass furniture manufacturers. Traditional mass production models, optimized for standardized products, are struggling to adapt to the evolving consumer preferences and the complexities of personalized design. This shift necessitates a reassessment of production processes, inventory strategies, and overall business models to remain competitive.

Impact on Production Processes and Efficiency

Mass production, reliant on standardized designs and components, is inherently less flexible than bespoke manufacturing. The introduction of customization introduces significant variability into the production pipeline. Each unique order requires tailored materials, specific dimensions, and potentially altered assembly sequences. This variability can lead to delays in production schedules and increased production time. For example, a mass-produced sofa line might take a few hours to assemble, whereas a custom-made version could take several days depending on the complexity of the modifications.

This increased production time directly impacts overall efficiency and throughput.

Impact on Inventory Management and Supply Chain Strategies

Traditional inventory management strategies, optimized for predictable demand, struggle to accommodate the fluctuating needs of a custom furniture market. Maintaining stock levels for every conceivable customization option becomes impractical and costly. Instead of warehousing a large array of components for various designs, manufacturers may need to adopt more agile supply chain strategies. This includes closer collaboration with suppliers to ensure timely delivery of specialized materials and potentially sourcing components on demand.

For example, a manufacturer might partner with suppliers specializing in bespoke fabrics or woods to ensure that they can readily procure the materials needed for each unique order.

Impact on Market Share

The rising popularity of custom furniture poses a clear threat to the market share of mass producers. Consumers increasingly seek unique pieces that reflect their individual styles and needs. As the custom furniture market grows, customers may be less inclined to settle for mass-produced alternatives, particularly if the quality and design of custom pieces align with their preferences.

This is particularly true for high-end furniture where uniqueness and personalized aesthetics are highly valued.

Adapting Production Strategies

Mass producers need to adapt their strategies to compete effectively in the custom furniture market. They need to balance the efficiency of mass production with the flexibility required for customized designs.

| Production Strategy | Description | Example |

|---|---|---|

| Modular Design | Dividing a product into interchangeable modules allows for various configurations, accommodating diverse customer preferences. | A sofa system with different sized and shaped modules enabling custom seating arrangements. |

| Agile Manufacturing | Implementing processes that facilitate rapid adaptation to changing customer demands, short lead times, and reduced inventory. | Employing just-in-time inventory systems and flexible production lines. |

| Customization Platforms | Utilizing online platforms or software to enable customers to design and customize products. | An online configurator that allows customers to choose fabrics, finishes, and dimensions for a sofa. |

| Strategic Partnerships | Collaborating with niche suppliers or designers specializing in bespoke elements to supplement mass production capabilities. | Partnering with a woodworker specializing in custom carvings or a fabric house to offer bespoke fabrics. |

| Focus on Value-Added Services | Offering additional services, such as design consultations or installation, to enhance the customer experience and differentiate from purely custom manufacturers. | Providing in-home consultations and design assistance for custom furniture projects. |

Adapting to the Changing Landscape

The furniture industry is undergoing a significant transformation, driven by a growing consumer preference for personalized and customized products. Mass furniture producers are challenged to adapt their existing models to meet this demand while maintaining cost-effectiveness and efficiency. This requires innovative strategies for integrating custom design elements into their production processes.This adaptation requires a multifaceted approach, moving beyond simply offering a few pre-selected customization options.

It necessitates a shift in mindset, embracing the potential of personalization as a driver of sales and brand differentiation. Understanding the strategies employed by successful companies in this area can provide valuable insight for other mass producers seeking to adapt.

Strategies for Incorporating Custom Design Elements

Mass producers can employ various strategies to seamlessly incorporate custom design elements into their production lines. These approaches range from simple modifications to complex digital design integrations.

- Modular Systems: Pre-fabricated modular components allow customers to assemble furniture according to their specific needs and preferences. This approach offers flexibility without compromising on efficiency. IKEA’s popular flat-pack furniture system is a prime example, allowing consumers to configure and arrange pieces in countless ways.

- Digital Design Tools: Integrating digital design tools into the production process enables customers to visualize and customize furniture online. This empowers them to make informed decisions and tailor pieces to their unique requirements. This approach allows for a higher degree of customer involvement and satisfaction.

- Customizable Configurations: Offering a range of pre-designed pieces with various customizable options, such as different finishes, colors, or sizes, allows customers to personalize their furniture without requiring a complete bespoke design. This approach leverages existing production lines while offering a degree of personalization.

Hybrid Solutions Through Collaboration

Strategic partnerships between mass producers and designers can foster the development of hybrid solutions. This approach combines the efficiency of mass production with the creativity and design expertise of external partners.

- Joint Design Studios: Collaboration with designers can create bespoke furniture collections that meet specific market needs. This model can create unique products while maintaining economies of scale.

- Licensing Agreements: Mass producers can license designs from independent designers, adding a unique touch to their product lines. This approach can attract new customers and enhance brand image.

Successful Adaptations of Mass Production Models

Several companies have successfully adapted their mass production models to accommodate customization.

- Herman Miller: This company has integrated customization options into its office furniture lines. They offer a wide range of customizable features and components, enabling clients to personalize their workspaces.

- IKEA: As mentioned earlier, IKEA’s modular flat-pack system is a well-established example of how mass production can accommodate customization by offering a variety of components that customers can combine to create unique pieces.

Leveraging Technology for Streamlined Custom Design

Technological advancements play a critical role in streamlining the custom design process for mass production.

- 3D Modeling and Printing: 3D modeling software allows for precise design iterations and enables the creation of custom components for furniture. 3D printing can then produce these components on demand, further facilitating personalization.

- AI-powered Design Tools: Artificial intelligence can assist in the design process, suggesting customized configurations based on customer preferences and space requirements. This streamlines the design process and enhances efficiency.

Pros and Cons of Adapting Strategies

| Strategy | Pros | Cons |

|---|---|---|

| Modular Systems | Flexibility, efficiency, cost-effectiveness | Potential for complexity in assembly, limited design freedom |

| Digital Design Tools | Enhanced customer experience, efficient design iterations | High initial investment in software, potential for design errors |

| Customizable Configurations | Increased personalization options, streamlined production | Limited scope of customization, potential for reduced profit margins |

| Joint Design Studios | Access to diverse design talent, unique product offerings | Potential for conflicts in design philosophies, increased complexity in production |

The Role of Technology

Technology is rapidly reshaping the custom furniture industry, empowering mass producers to meet the increasing demand for personalized pieces while maintaining efficiency and cost-effectiveness. This evolution is driven by innovative software and automated processes that streamline design, production, and ultimately, the customer experience.The integration of technology allows for greater customization and flexibility, moving beyond the limitations of traditional manufacturing methods.

This approach fosters a more dynamic relationship between the manufacturer and the customer, enabling a more responsive and personalized experience.

3D Modeling and Digital Design Tools

D modeling software has revolutionized the design process for custom furniture. Designers can now create intricate and detailed models, allowing customers to visualize their furniture in their desired spaces before production begins. This iterative process, facilitated by real-time visualization, minimizes errors and ensures customer satisfaction. Interactive tools enable customers to manipulate designs, explore different materials, and offer feedback directly within the design process.

This enhanced level of collaboration leads to a more streamlined design phase, reducing costly revisions and accelerating the project timeline.

Automated Manufacturing Processes

Automated manufacturing processes, such as CNC machining and robotic assembly, are significantly impacting the production of custom furniture. These technologies increase precision and consistency in manufacturing, enabling mass producers to tackle intricate designs and complex joinery with unprecedented accuracy. This precision also helps to minimize material waste, reducing production costs and enhancing sustainability. Robotic arms can perform repetitive tasks with high speed and precision, enabling manufacturers to adapt quickly to varying order quantities and complexities.

This increased efficiency leads to a more responsive and adaptive production line.

Responding to Individual Customer Preferences

Technology plays a critical role in enabling mass producers to cater to diverse customer preferences. Customizable design platforms allow customers to select from a wide array of materials, finishes, and configurations. This level of personalization, previously not feasible in mass production, creates a highly competitive advantage for companies able to adapt to these technological advancements. Real-time inventory management systems ensure materials are readily available for individual orders, minimizing lead times and enhancing customer satisfaction.

The integration of these systems also empowers companies to track customer preferences and tailor future offerings.

Challenges and Opportunities of Integrating Technology

Integrating technology into existing production lines presents both challenges and opportunities. Significant upfront investment in new software and machinery is often required, along with a need for skilled personnel to operate and maintain the equipment. Training existing staff on new technologies and processes is crucial to ensuring a smooth transition. However, the long-term benefits often outweigh these initial costs.

Streamlined processes, enhanced efficiency, and greater customer satisfaction ultimately contribute to increased profitability and market share. Furthermore, the ability to adapt to ever-changing customer demands is greatly enhanced.

Software Tools in Custom Furniture Design and Manufacturing

| Software Category | Software Name (Example) | Description |

|---|---|---|

| 3D Modeling | SketchUp, Blender, Rhino | These software tools facilitate the creation of 3D models of furniture designs, enabling visualization and manipulation of designs. |

| CAD (Computer-Aided Design) | AutoCAD, SolidWorks | CAD software assists in the creation of 2D and 3D designs for components and parts, crucial for detailed drawings and manufacturing specifications. |

| CAM (Computer-Aided Manufacturing) | Mastercam, Fusion 360 | CAM software translates 3D designs into instructions for CNC machines, ensuring accurate production of parts. |

| ERP (Enterprise Resource Planning) | SAP, Oracle | ERP systems manage the entire production process, from order processing to inventory management, crucial for efficient custom furniture production. |

The Future of the Market

The custom furniture market is poised for significant growth, driven by evolving consumer preferences and technological advancements. Consumers increasingly desire unique, personalized pieces that reflect their individual style and lifestyle, creating a substantial opportunity for producers who can adapt to this demand. This shift from mass-produced to bespoke solutions presents both challenges and exciting possibilities for the future of the industry.

Forecasting Future Trends

The custom furniture market is projected to experience sustained growth in the coming years. This anticipated expansion is influenced by a combination of factors, including the rising demand for personalized products and the increasing availability of advanced manufacturing technologies. For example, the popularity of home renovation projects and the desire for unique décor elements are fueling the demand for customized pieces.

This trend is further strengthened by the growing awareness of sustainability and the demand for environmentally friendly materials and production methods. As a result, companies focusing on sustainability and offering a personalized approach are likely to be more successful in the long term.

Emerging Technologies and Trends

Several emerging technologies are poised to revolutionize the custom furniture industry. 3D printing, for example, allows for complex and intricate designs, enabling greater customization and potentially reducing production costs. Additive manufacturing techniques are enabling the creation of customized furniture components that were previously impossible to produce. Furthermore, advancements in digital design and visualization tools empower consumers to actively participate in the design process, leading to more personalized and engaging experiences.

These developments are not just limited to furniture production; the entire design and ordering process can be streamlined and personalized through digital tools.

Consumer Preferences and Industry Impact

Consumer preferences are evolving towards greater personalization and sustainability. Consumers are increasingly seeking furniture that reflects their unique style and lifestyle, and they are also becoming more aware of the environmental impact of their purchases. This translates into a growing demand for ethically sourced materials, sustainable production methods, and furniture that can be easily repaired or repurposed. Companies that prioritize sustainability and offer customization options are well-positioned to capture this market segment.

The growing interest in sustainable materials like reclaimed wood and bamboo, for example, underscores this trend.

Positioning Mass Producers for Success, The Global Demand for Custom Furniture: A Challenge for Mass Producers

Mass producers can successfully navigate the shift towards custom furniture by adopting a flexible and adaptable approach. Investing in digital design tools and 3D modeling software can enhance their ability to quickly create and iterate on custom designs. Collaborating with design professionals or integrating design platforms into their operations can further streamline the customization process. Furthermore, developing strategic partnerships with suppliers of sustainable materials can contribute to a stronger market presence.

This involves more than just selling furniture; it’s about creating an experience.

Key Factors Influencing Future Growth

| Factor | Description | Impact |

|---|---|---|

| Consumer Demand for Personalization | Consumers increasingly desire unique and customized furniture. | Increased demand for custom furniture, driving growth. |

| Technological Advancements | 3D printing, digital design tools, and other technologies enhance customization and efficiency. | Improved production methods, reduced costs, and increased personalization. |

| Sustainability Concerns | Growing awareness of environmental impact drives demand for eco-friendly materials and production methods. | Increased demand for sustainable furniture, potentially creating new market segments. |

| Evolving Consumer Preferences | Shifting preferences towards sustainable, durable, and customizable products. | Companies need to adapt to meet these evolving needs. |

| Market Competition | Increased competition from specialized custom furniture makers. | Companies must differentiate themselves through innovation and quality. |

Illustrative Examples of Customization

Mass-produced furniture, while often economical, can sometimes lack the unique character and tailored functionality that bespoke pieces offer. However, innovative companies are increasingly recognizing the demand for personalized options within the mass-production framework. This allows them to cater to a broader customer base while still maintaining production efficiency.Customizable elements within mass-produced furniture can significantly enhance its appeal and functionality, often exceeding the appeal of standard, off-the-shelf items.

By incorporating diverse customization options, manufacturers can foster customer satisfaction and create a more dynamic and appealing product offering.

Color Variations

Customization frequently begins with color choices. Offering a range of paint finishes, stains, or even specialized coatings allows consumers to personalize the aesthetic of their furniture. For example, a company might offer a line of modular shelving units in a palette of 10 standard colors, with the option to add a custom paint job in any RAL color.

This allows for a wide range of possibilities, from classic neutrals to bold statements. A modern living room, for example, might be enhanced by a set of dark-grey cabinets that perfectly complement the existing décor.

Material Upgrades

Beyond color, material upgrades offer significant customization opportunities. A company producing wooden furniture might offer customers the option to upgrade from standard plywood to solid hardwood for a more durable and luxurious feel. Or, in the case of metal furniture, different metal types, finishes, or even the addition of textured surfaces can elevate the piece’s aesthetic and longevity.

For example, an office chair might allow customers to choose between a standard mesh back and a premium leather back. This caters to different needs and preferences.

Unique Features and Add-ons

Adding unique features or accessories to mass-produced furniture provides a further avenue for customization. A company producing storage units might offer optional add-ons such as drawers, shelves, or even specialized lighting fixtures. These elements allow consumers to tailor the functionality of their furniture to meet their specific needs. For instance, a standard dining table could be upgraded with a hidden lift-top mechanism for increased storage space.

Case Studies of Successful Customization

Several companies have successfully implemented customization options for mass-produced furniture. IKEA, for example, offers a wide array of customization options for its furniture, including color choices, accessory add-ons, and even custom-sized components for particular needs. Likewise, companies specializing in modular office furniture often allow customers to configure their office spaces with customized combinations of desks, chairs, and storage solutions.

Illustrative Example – Image Description

Imagine a mass-produced bookshelf, featuring a basic rectangular design in a light oak finish. The image on the left shows the standard model. The image on the right displays the same bookshelf, customized with a dark gray paint finish and a set of brass-colored metal brackets that add a touch of industrial style. This demonstrates how simple customization can significantly alter the visual appeal of a mass-produced item.

Final Summary

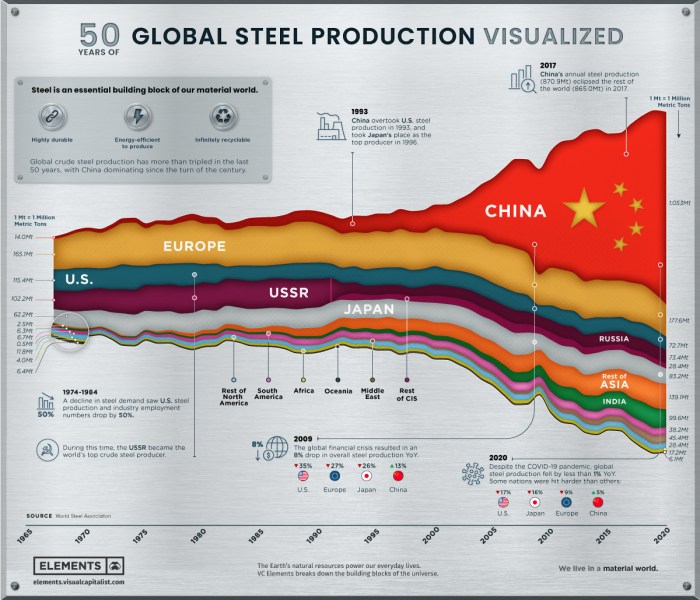

Source: visualcapitalist.com

In conclusion, the global demand for custom furniture is reshaping the landscape of the furniture industry. Mass producers face a crucial choice: either adapt to the growing demand for personalization or risk losing market share. The article has explored the various challenges and opportunities presented by this trend, highlighting the importance of technological advancements and strategic collaborations to meet the evolving needs of consumers.

The future success of mass producers hinges on their ability to embrace customization while maintaining efficiency and profitability.

Commonly Asked Questions: The Global Demand For Custom Furniture: A Challenge For Mass Producers

What are the key factors driving the demand for custom furniture?

Factors include a desire for unique style, a need for furniture that perfectly fits specific spaces, and a preference for high-quality, durable materials.

How does customization affect inventory management for mass producers?

Customization necessitates more complex inventory systems and potentially reduced economies of scale. Mass producers must carefully manage the diversity of materials and configurations.

What are some examples of successful adaptations by mass producers to meet the demand for custom furniture?

Examples include offering modular furniture systems that allow for configuration and customization, allowing for personalization of color and material choices, or providing online design tools for customers to visualize their customized pieces.

What are the potential long-term implications for mass producers who fail to adapt to the custom furniture trend?

Failure to adapt could lead to a loss of market share to companies specializing in custom furniture and a diminished customer base.