Inside the Next Generation of Custom Furniture Manufacturing, a revolution is underway, transforming the industry through technological advancements, innovative materials, and evolving business models. This new era is characterized by a blend of cutting-edge design and meticulous craftsmanship, pushing the boundaries of what’s possible in custom furniture. The shift encompasses everything from digital design tools to automated production processes, altering the very fabric of how custom furniture is conceived and created.

This evolving landscape presents both exciting opportunities and considerable challenges. The integration of technology promises to enhance efficiency, personalize the customer experience, and potentially lower production costs. However, the need to adapt existing supply chains, embrace ethical sourcing, and navigate the complexities of digital marketing are crucial for success. The future of custom furniture manufacturing hinges on embracing this dynamic evolution.

Defining the Next Generation

Source: furnituredesignindia.com

The custom furniture manufacturing industry is undergoing a profound transformation, driven by technological advancements and evolving consumer demands. This new era is characterized by a fusion of traditional craftsmanship with cutting-edge technology, resulting in a more efficient, personalized, and sustainable approach to furniture creation. This shift is creating opportunities for innovation and customization that were previously unimaginable.This next generation of custom furniture manufacturing is not simply an evolution, but a paradigm shift.

It’s about leveraging technology to enhance craftsmanship, improve efficiency, and ultimately, deliver a superior product. This transformation is fueled by digital design tools, innovative materials, and new manufacturing processes. The outcome is a more sustainable and customer-centric approach to furniture creation.

Key Characteristics of Contemporary Custom Furniture Manufacturing

Contemporary custom furniture manufacturing stands apart from previous generations due to its integration of technology, emphasis on sustainability, and heightened focus on personalized design. Traditional methods often relied on manual processes and limited design options. This new generation leverages digital tools to streamline design, material selection, and production, enabling unparalleled customization for the client.

Technological Advancements

Digital design tools, 3D modeling software, and advanced CNC machining are reshaping the landscape of custom furniture production. These technologies enable designers to create intricate designs with precision and speed previously unattainable. Sophisticated software allows for real-time visualization and modification of designs, enabling customers to actively participate in the design process and refine their vision. Furthermore, advanced CNC routers and automated assembly lines are enhancing efficiency and reducing production time.

Innovative Materials and Manufacturing Processes

The use of innovative materials and manufacturing processes is defining the next generation. Sustainable materials like reclaimed wood, bamboo, and recycled plastics are gaining popularity, reflecting a growing awareness of environmental responsibility. Advanced composite materials, offering superior strength and durability, are also gaining traction. Additive manufacturing (3D printing) is emerging as a game-changing technology, allowing for complex and intricate designs that were previously impossible to create using traditional methods.

Examples include furniture with unique, organic shapes, intricate designs, or customized structural elements. Bio-based materials are also being explored for their potential to offer both aesthetic appeal and environmental benefits.

Digital Design Tools

Digital design tools are fundamentally reshaping the custom furniture industry. Software allows designers to create and refine designs with unprecedented precision and speed. These tools enable customers to visualize their furniture in their space, facilitating better design choices and personalized solutions. Furthermore, digital design fosters greater collaboration between designers, manufacturers, and clients, enabling a more iterative and collaborative design process.

Emerging Trends

Emerging trends in custom furniture manufacturing include a greater emphasis on sustainability, personalization, and customer collaboration. Consumers are increasingly seeking furniture that aligns with their environmental values. Customizable features are becoming more sophisticated, allowing customers to tailor every aspect of their furniture to their specific needs and preferences. Furthermore, digital platforms are facilitating direct communication and collaboration between clients and designers, leading to more responsive and tailored design solutions.

Comparison of Traditional and Modern Approaches

| Feature | Traditional | Modern | Impact |

|---|---|---|---|

| Design Process | Hand-drawn sketches, physical prototypes, limited client interaction | Digital design software, 3D modeling, virtual reality, client collaboration | Increased design flexibility, quicker iteration, enhanced client engagement |

| Material Selection | Limited options, often dictated by availability and cost | Wider range of materials, including sustainable and innovative options, cost-effective material exploration | Enhanced design choices, environmental considerations, better material performance |

| Production Methods | Manual labor, slower production, limited customization | Automated processes, CNC machining, additive manufacturing, faster production | Increased production efficiency, reduced lead times, intricate customization |

| Customization Options | Limited customization, often based on pre-defined options | Highly customizable, tailored to individual needs, digitally designed to specific dimensions and features | Greater client satisfaction, unique furniture pieces, personalized experience |

The Role of Technology: Inside The Next Generation Of Custom Furniture Manufacturing

Modern custom furniture manufacturing is undergoing a rapid transformation, driven by the integration of advanced technologies. These innovations are impacting every aspect of the process, from design and prototyping to production and delivery. This evolution promises increased efficiency, greater customization options, and a more sustainable approach to manufacturing.The application of automation and robotics, coupled with sophisticated software and 3D modeling, is revolutionizing the way furniture is made.

This allows for a more agile and responsive approach to meet the diverse needs of clients, ultimately enhancing the overall customer experience.

Automation and Robotics

Automation and robotics are playing a crucial role in streamlining production processes. Automated cutting and assembly lines are becoming increasingly common, reducing human error and improving consistency. Robots are now capable of performing complex tasks, such as precise joinery and intricate finishing operations, further enhancing production efficiency and accuracy. This automation not only boosts productivity but also minimizes the reliance on manual labor, reducing labor costs and safety risks.

For instance, robotic arms can handle delicate tasks with superior precision and speed, optimizing the construction of custom-designed furniture components.

3D Printing and Additive Manufacturing

D printing and other additive manufacturing techniques are significantly altering the design and production landscape. This technology allows for the creation of complex geometries and intricate designs that were previously impractical or impossible to achieve using traditional methods. Custom shapes and unique features can be effortlessly integrated into the design, opening new avenues for creativity and customization. Moreover, this technology enables the creation of prototypes quickly and cost-effectively, facilitating iterative design processes and client feedback loops.

This iterative process enables the production of more tailored furniture pieces to meet individual customer needs.

AI and Machine Learning

AI and machine learning are optimizing production processes by analyzing vast amounts of data. Predictive maintenance algorithms can identify potential equipment failures before they occur, reducing downtime and optimizing resource allocation. Furthermore, AI-powered systems can optimize material usage, ensuring minimal waste and maximizing efficiency. These systems can also analyze customer preferences and trends to predict future demands, thereby enabling businesses to proactively adapt and tailor their production strategies to meet evolving customer needs.

For example, AI-driven systems can analyze historical sales data and customer feedback to predict upcoming design trends, allowing furniture manufacturers to anticipate and fulfill customer desires more accurately.

Technology Implementation in Custom Furniture Manufacturing

| Technology | Benefits | Challenges | Solutions |

|---|---|---|---|

| 3D Printing | Enhanced design flexibility, rapid prototyping, reduced material waste, creation of complex geometries | High initial investment cost, limited material choices, potential quality inconsistencies | Exploring various 3D printing technologies (SLA, SLS, FDM), investing in high-quality materials, implementing stringent quality control measures |

| AI | Optimized production processes, predictive maintenance, improved resource allocation, personalized customer experiences | Data security concerns, potential for bias in algorithms, need for skilled personnel | Robust data encryption protocols, algorithm validation, training and upskilling of personnel |

| Robotics | Increased precision and speed, reduced human error, enhanced safety, improved consistency | High initial investment, potential for job displacement, complexity of integration into existing workflows | Investing in collaborative robots (cobots), strategic workforce retraining, and implementing phased integration of robotics |

Enhancing Design and Customization

Technology is significantly enhancing the design and customization options for custom furniture. 3D modeling software enables clients to visualize their furniture ideas in a virtual environment, allowing for detailed iterations and adjustments before physical production. This iterative process enhances the customer experience, allowing for a more seamless collaboration between designers and clients. Moreover, AI-powered design tools can generate numerous design options based on user input, further expanding the scope of customization possibilities.

For instance, clients can use virtual reality (VR) technology to virtually experience and interact with their customized furniture designs before purchasing.

Supply Chain Dynamics

Source: dreamstime.com

The custom furniture industry, with its focus on bespoke designs and unique client specifications, faces unique challenges in managing its supply chain. Traditional models often struggle to adapt to the fluctuating demands and intricate specifications of custom orders. Modern approaches are necessary to ensure efficiency, sustainability, and resilience in the face of evolving market conditions.

Evolving Dynamics of the Supply Chain

The traditional supply chain in custom furniture manufacturing often relied on established relationships with suppliers for raw materials, components, and skilled labor. This frequently involved longer lead times and less transparency into the production process. Modern approaches are leveraging technology to enhance communication, tracking, and collaboration. Digital platforms and supply chain management software enable real-time visibility into inventory levels, order statuses, and potential delays.

This allows for quicker adjustments and more efficient responses to unexpected circumstances.

Comparison of Traditional and Modern Approaches

Traditional supply chains often prioritized cost efficiency over speed and flexibility. They frequently relied on bulk purchasing and long-term contracts. Modern approaches, however, emphasize agility and responsiveness to individual client needs. They involve establishing more diverse supplier networks, enabling faster lead times for materials and components, and often use just-in-time inventory management. This flexibility allows for the customization and personalization required in the custom furniture industry.

Potential Disruptions and Risks

Potential disruptions in the custom furniture supply chain encompass a wide range of factors. Geopolitical instability, natural disasters, and pandemics can significantly impact material sourcing and transportation. Fluctuations in raw material prices, especially for wood and metal, are also significant concerns. Furthermore, labor shortages in specific trades or skillsets can affect production timelines and quality control.

Strategies for Ensuring Resilience and Sustainability

Ensuring the resilience of the supply chain necessitates a multi-faceted approach. Diversifying sourcing strategies, developing strong relationships with multiple suppliers, and implementing robust contingency plans are crucial. Building a resilient supply chain is intrinsically linked to sustainability. Prioritizing environmentally friendly materials, promoting ethical sourcing, and adopting lean manufacturing principles can significantly reduce the environmental footprint of the entire process.

Ethical Sourcing and Responsible Production Practices

Ethical sourcing is paramount in the custom furniture industry. It involves ensuring that materials are sourced responsibly and that labor practices adhere to fair labor standards. Transparency and traceability throughout the supply chain are essential. Companies should actively work with suppliers who uphold ethical standards and ensure safe working conditions for their employees. This commitment to ethical sourcing fosters trust and builds a reputation for social responsibility.

Materials Sourcing and Ethical/Sustainability Considerations

| Material Type | Sourcing Method | Ethical Considerations | Sustainability Impact |

|---|---|---|---|

| Wood | Sustainable forestry practices, certified timber, local sourcing where possible | Ensuring wood comes from responsibly managed forests, avoiding illegal logging, and respecting indigenous communities’ rights. | Lowering carbon footprint, promoting biodiversity, and supporting forest conservation. |

| Metal | Recycled metal, ethically sourced ores, responsible mining practices | Ensuring fair wages and safe working conditions for miners, and avoiding the use of conflict minerals. | Reducing reliance on virgin materials, minimizing environmental impact from mining, and promoting circularity. |

| Fabric | Organic materials, recycled fabrics, locally produced fabrics | Ensuring fair wages and safe working conditions for textile workers, and avoiding the use of child labor. | Reducing water usage, minimizing chemical pollution, and promoting sustainable agriculture. |

Business Models and Strategies

Source: designindaba.com

The custom furniture industry is undergoing a transformation, driven by evolving consumer preferences and technological advancements. This shift necessitates a re-evaluation of traditional business models to accommodate the demand for personalized and innovative designs. Companies are adapting to offer unique value propositions and optimize their operations to meet these evolving expectations.

Emerging Business Models

The custom furniture industry is seeing a rise in diverse business models beyond the traditional direct-to-consumer approach. Subscription-based services, offering curated collections or modular furniture, are becoming increasingly popular. This allows customers to access a variety of designs while maintaining flexibility. Other models focus on providing design services, allowing customers to collaborate with designers from the initial concept phase, and offering complete project management, creating a streamlined process for customers.

These models cater to different needs and budgets, making the industry more accessible and desirable.

Successful Company Examples

Several companies are successfully adopting new business models. For instance, “The Bespoke Collective” leverages a subscription-based model, allowing customers to rotate furniture collections. Similarly, “Modular Designs” offers modular furniture components, allowing for flexible and customizable configurations. These companies demonstrate how innovation in business models can create new avenues for growth and cater to modern consumer needs.

Customer Engagement and Experience

Exceptional customer engagement and experience are paramount in the custom furniture industry. This includes providing personalized consultations, detailed design processes, and proactive communication throughout the manufacturing process. Modern customers value transparency and the ability to visualize their furniture in their space. Companies are utilizing virtual reality (VR) and augmented reality (AR) tools to facilitate this visualization process.

Marketing and Sales Strategies

Modern marketing strategies emphasize personalized customer experiences and focus on building strong brand narratives. Custom furniture manufacturers utilize digital marketing platforms such as social media, websites, and online marketplaces to showcase their products and engage with potential clients. They leverage social media platforms for design inspiration, behind-the-scenes glimpses of the manufacturing process, and to create a community around their brand.

Digital Marketing and Online Sales Channels

Online sales channels are increasingly vital for reaching a broader customer base. Websites with interactive design tools, 3D visualizations, and detailed product information are crucial. This allows customers to explore options and make informed decisions, even before physically visiting a showroom. Direct-to-consumer e-commerce platforms allow for streamlined transactions and personalized customer service.

Customer Service and Support, Inside the Next Generation of Custom Furniture Manufacturing

Exceptional customer service is vital for building trust and loyalty. Custom furniture manufacturers must provide responsive communication, detailed explanations about the manufacturing process, and options for addressing potential issues during and after delivery. Building a dedicated customer support team equipped to handle inquiries and resolve problems quickly is critical.

Vision of a Successful Custom Furniture Company

“Our vision is to empower customers to create unique, personalized spaces through bespoke furniture designs, crafted with sustainable materials and unparalleled craftsmanship. We aim to provide a seamless and inspiring journey from initial design concept to final delivery, fostering lasting relationships with our clientele.”

Design and Customization

Source: aopackmachine.com

The realm of custom furniture is undergoing a significant transformation, driven by evolving design aesthetics, sophisticated design tools, and a growing emphasis on personalized experiences. Manufacturers are adapting to meet the increasing demand for unique and bespoke pieces, leveraging technology to streamline the design process and cater to diverse customer preferences.This evolution extends beyond mere material choices; it encompasses a holistic approach to design, from initial concept to final delivery.

The interplay of aesthetics, technology, and customer experience forms the bedrock of this new era in custom furniture manufacturing.

Evolution of Design Aesthetics and Trends

Contemporary custom furniture design often reflects a blend of styles, drawing inspiration from mid-century modern, Scandinavian minimalism, and industrial chic. Sustainable materials and eco-conscious design choices are gaining traction, as customers increasingly prioritize environmentally friendly options. Geometric patterns and abstract forms are also finding their place in modern designs, often integrated with innovative fabrication techniques.

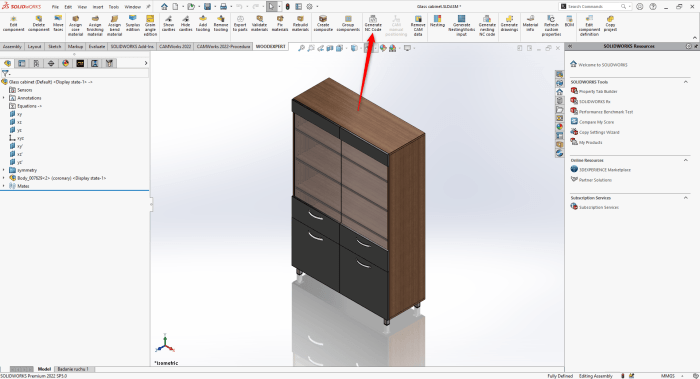

Role of Design Software and Tools

Design software plays a crucial role in the custom furniture design process. CAD (Computer-Aided Design) programs allow designers to create detailed 3D models, enabling precise visualization and manipulation of furniture pieces before physical production. These tools facilitate iterations and adjustments, leading to optimal design solutions. Advanced software also allows for material simulations, enabling designers to explore different finishes and textures virtually.

The use of parametric design tools allows for easy modification of designs based on customer input.

Methods for Achieving Precise Customization Requests

Achieving precise customization requires a robust system for gathering customer input. Interactive online design platforms allow customers to visualize their desired furniture in a virtual environment, selecting from a wide range of materials, finishes, and dimensions. Collaboration tools facilitate seamless communication between designers and customers, ensuring that every detail aligns with expectations. 3D modeling tools and precise measurement tools ensure that customization requests are accurately translated into the final product.

Enhancement of User Experience in Design and Selection

User experience is being enhanced by intuitive online platforms and personalized design consultations. Interactive design tools provide customers with an immersive experience, allowing them to explore different options and personalize their furniture virtually. Designers play a crucial role in guiding customers through the selection process, offering insights and recommendations based on their preferences and needs.

Examples of Exceptional Custom Furniture Designs

Numerous examples showcase the creativity and innovation in custom furniture design. A notable example is a custom-designed library built using reclaimed wood, incorporating intricate carvings and custom lighting to create a unique and functional space. Another compelling example features a modern dining table crafted from sustainable bamboo, showcasing clean lines and a minimalist aesthetic.

Techniques for Presenting Design Concepts to Customers

Presenting design concepts effectively is critical. High-quality renderings and 3D models offer customers a realistic preview of their future furniture. Virtual reality (VR) experiences can take this a step further, immersing customers in the design environment. Designers often use interactive presentations, highlighting key features and addressing potential concerns. Visual aids, such as mood boards and material samples, also play a vital role in helping customers visualize their vision.

Customization Options for Custom Furniture

| Customization Type | Example | Cost Considerations | Design Considerations |

|---|---|---|---|

| Material Selection | Solid wood, veneer, metal, glass, fabric | Different materials have varying costs based on availability and quality. | Material selection influences the overall aesthetic, durability, and maintenance requirements. |

| Dimensions | Adjusting length, width, height, and depth | Larger dimensions generally incur higher costs due to increased material use and labor. | Careful consideration of space constraints and functionality is critical. |

| Color | Custom paint colors, stained finishes, or fabric upholstery | Custom colors can affect costs based on the complexity of the application. | Color selection should complement the overall design and interior decor. |

| Hardware | Custom drawer pulls, knobs, or hinges | Cost depends on the type and quality of the hardware. | Hardware choice should align with the overall style and aesthetic of the furniture. |

| Finishes | Polishing, lacquering, or other surface treatments | Different finishes have different costs and maintenance requirements. | Finishes contribute significantly to the overall aesthetic and durability of the furniture. |

Final Summary

Source: woodexpert3d.com

In conclusion, the next generation of custom furniture manufacturing is marked by a fusion of tradition and innovation. This dynamic evolution is driven by technological advancements, a reimagining of supply chains, and a focus on customer-centric design and experiences. The industry’s future success hinges on manufacturers’ ability to leverage these changes, adapt to evolving market demands, and embrace a sustainable and ethical approach to production.

User Queries

What are the key differences between traditional and modern approaches to custom furniture design?

Traditional methods often rely on manual processes, while modern approaches leverage digital design tools and automation for greater efficiency and customization.

How is AI impacting the production process in custom furniture?

AI is being utilized to optimize production processes, predict potential issues, and personalize the manufacturing process to meet individual customer needs.

What are the ethical considerations surrounding material sourcing in custom furniture?

Ethical sourcing is paramount. Manufacturers must ensure that materials are obtained responsibly, avoiding exploitation and promoting sustainable practices throughout the supply chain.

What are the emerging business models in the custom furniture industry?

Emerging models include direct-to-consumer sales, online design platforms, and collaborations with interior designers. These methods aim to provide customers with a more seamless and personalized experience.