Improving Efficiency in Furniture Factories is crucial for staying competitive in today’s market. This guide delves into key strategies to optimize production, from planning and scheduling to material handling and assembly processes. We’ll explore the integration of technology, the importance of employee training, and sustainable practices. By implementing these methods, factories can streamline operations, reduce costs, and enhance overall performance.

The article will cover a range of topics, including detailed production planning methods, efficient material handling techniques, and streamlined assembly processes. We’ll also discuss quality control measures, the integration of advanced technologies, and the significance of employee training and development. Finally, we’ll examine strategies for optimizing the supply chain and reducing waste, ensuring both profitability and environmental responsibility.

Production Planning & Scheduling

Optimizing production schedules is crucial for furniture factories to meet customer demands efficiently and reduce costs. Effective planning and scheduling minimize bottlenecks, leading to higher output and improved profitability. This involves meticulous consideration of various factors, including forecasting demand, resource allocation, and real-time monitoring of progress.A well-structured production plan allows furniture factories to proactively address potential issues and maintain a smooth workflow, thereby increasing overall productivity and customer satisfaction.

Forecasting demand, in particular, is vital for adjusting production schedules and inventory levels to meet fluctuations in market demand.

Optimizing Production Schedules

Effective production scheduling in furniture factories involves a multi-step process that considers various factors. A crucial element is the use of a detailed schedule, outlining the sequence of tasks for each piece of furniture, from raw material procurement to final assembly. This schedule should consider the capacity of each workstation, the time required for each operation, and the availability of materials and personnel.

By aligning production schedules with projected demand, factories can avoid overproduction or shortages, thereby minimizing waste and maximizing efficiency.

Forecasting Demand

Accurate forecasting of demand for different furniture items is fundamental to effective production planning. Several approaches exist for predicting future demand, including analyzing historical sales data, identifying trends in customer preferences, and considering external factors such as economic conditions and seasonal variations. For example, analyzing past sales data, noting seasonal patterns, and considering economic indicators can help furniture manufacturers anticipate future demand fluctuations and adjust their production schedules accordingly.

A thorough understanding of customer preferences is also vital. This could involve market research, customer surveys, or analysis of social media trends to predict emerging trends in furniture styles.

Real-Time Production Tracking

Real-time tracking of production progress is essential for identifying potential delays or issues promptly. A system that monitors the status of each piece of furniture throughout the production process, from raw material cutting to final assembly, provides valuable insights into potential bottlenecks or inefficiencies. This data can be used to take proactive steps to resolve problems before they escalate.

A digital dashboard or a similar system displaying the current status of each order can be beneficial in achieving this real-time tracking. This visual representation allows for immediate identification of delays or discrepancies.

Production Scheduling Software Comparison

Implementing a dedicated software solution for production scheduling can streamline operations and improve efficiency. Various software options are available, each with its own strengths and weaknesses. The choice of software should be tailored to the specific needs and resources of the furniture factory.

| Software | Key Features | Benefits |

|---|---|---|

| Planview EnterpriseOne | Advanced resource management, comprehensive scheduling, and real-time tracking. | Enhanced visibility into production progress, improved resource utilization, and reduced lead times. |

| SAP ERP | Integrates with other business functions, providing a holistic view of the entire production process. | Streamlined workflows, improved communication between departments, and better control over inventory. |

| Microsoft Project | Provides project management tools for scheduling individual projects or tasks. | Easy-to-use interface, robust scheduling capabilities, and compatibility with other Microsoft products. |

| Odoo | Comprehensive suite with features for production planning, inventory management, and sales order processing. | Improved efficiency across different aspects of the business, including inventory management and customer order fulfillment. |

Material Handling & Logistics

Optimizing material handling and logistics is crucial for a furniture factory’s efficiency. Streamlined movement of raw materials, components, and finished goods throughout the production process reduces lead times, minimizes storage costs, and enhances overall productivity. Effective material flow directly impacts the ability to meet customer demands and maintain profitability.

Best Practices for Efficient Material Handling

Implementing best practices for material handling ensures a smooth flow from receiving to assembly. Clear material pathways and designated zones for different stages of production minimize congestion and improve safety. Utilizing barcode scanning or RFID tagging for inventory management facilitates real-time tracking and accurate inventory counts. Regular audits of material handling processes and employee training on best practices are essential for continuous improvement.

Automated Material Handling Systems

Automated material handling systems offer significant potential for enhancing efficiency in furniture factories. Automated guided vehicles (AGVs) can transport materials between different workstations, minimizing manual handling and reducing errors. Automated storage and retrieval systems (AS/RS) optimize warehouse space and enable faster retrieval of components. Robotic arms can automate tasks like loading and unloading, improving speed and precision.

Integration with enterprise resource planning (ERP) systems further streamlines the entire process, providing real-time visibility and control over material flow.

Warehouse Layout and Storage Optimization

Optimizing warehouse layout and storage directly impacts material handling time. Strategically positioning workstations and storage areas in close proximity to assembly lines reduces travel time and minimizes material movement. Utilizing efficient storage solutions, such as racking systems and shelving, maximizes space utilization and reduces the time needed to locate and retrieve materials. Implementing a first-in, first-out (FIFO) inventory system ensures that older materials are used before newer ones, preventing obsolescence and maintaining freshness of raw materials, especially in the case of wood.

Regular inventory audits and a proactive approach to managing storage space can prevent stockouts and delays in production.

Conveyors and Their Suitability

Proper selection of conveyors for different production stages is crucial. The choice of conveyor type should be aligned with the specific needs of each stage, considering factors like the volume of material, the weight of items, and the required speed.

| Conveyor Type | Suitability for Furniture Production Stages |

|---|---|

| Belt Conveyors | Suitable for transporting large volumes of raw materials, components, and finished products in the receiving and shipping areas. Also applicable for moving smaller parts within assembly areas, particularly if the parts are not particularly delicate. |

| Roller Conveyors | Ideal for transporting smaller, lighter items between assembly workstations. Their gentle handling characteristics are beneficial for delicate components and products. |

| Overhead Conveyors | Useful for transporting materials between different floors or elevated assembly stations. Efficient for maximizing vertical space and reducing congestion in the factory floor. |

| Screw Conveyors | Effective for transporting bulk materials like wood, screws, or other raw materials. Generally used in receiving or warehousing stages. |

| Chain Conveyors | Suitable for transporting materials over longer distances, especially in assembly lines. Often utilized for moving heavy components or multiple items in a specific order. |

Assembly & Manufacturing Processes: Improving Efficiency In Furniture Factories

Optimizing assembly and manufacturing processes is crucial for furniture factories seeking to enhance efficiency and reduce production costs. A well-designed assembly line, incorporating streamlined workflows and ergonomic considerations, significantly impacts overall output and worker satisfaction. This section explores techniques to streamline assembly lines, different assembly methods, and strategies for improving worker well-being and eliminating waste.Effective assembly processes directly influence the speed and quality of furniture production.

Implementing efficient assembly methods, coupled with a commitment to worker well-being, creates a positive feedback loop, leading to higher output and reduced production costs.

Streamlining Assembly Lines

A well-structured assembly line is a cornerstone of efficient furniture production. Careful consideration of workstation layout and task allocation is critical. Workstations should be strategically positioned to minimize movement and maximize workflow efficiency. Efficient task allocation distributes work evenly among team members, ensuring no bottlenecks or uneven workload distribution.

- Workstation Design: Ergonomic design is paramount. Workstations should be designed to accommodate various body types, ensuring comfortable and safe postures for workers. Adequate space for tools, materials, and movement is also crucial to minimize delays and maximize efficiency. Clear visual aids and signage can guide workers, reducing errors and promoting consistency.

- Task Allocation: Tasks should be divided logically and assigned based on worker skill sets and capabilities. This allows for specialization, leading to increased efficiency and reduced errors. Training programs for tasks can improve consistency and reduce the need for extensive rework. Regular monitoring of task performance can identify areas needing adjustment.

Comparing Assembly Methods

Different assembly methods have varying impacts on efficiency and cost. Choosing the appropriate method depends on the complexity of the furniture, the required production volume, and the desired level of customization.

- Modular Assembly: This approach involves pre-assembling modules or components off-line. This method enhances efficiency by reducing on-site assembly time. Specialized equipment can be used for modular assembly, increasing speed and accuracy. This method is suitable for standardized furniture production and allows for flexibility in the configuration of final products. For example, a kitchen cabinet can be pre-assembled into modules, which are then joined together on the assembly line.

- Prefabricated Components: Using prefabricated components significantly reduces assembly time and labor costs. Standardized components can be manufactured in advance, facilitating a more streamlined assembly process. This is particularly effective for furniture with repeating elements or designs. For example, the use of pre-cut panels and pre-drilled components for shelving units speeds up the assembly process considerably.

Improving Worker Ergonomics, Improving Efficiency in Furniture Factories

Worker well-being is directly linked to productivity. Minimizing physical strain and fatigue reduces errors and increases worker satisfaction.

- Reducing Fatigue: Implementing ergonomic principles at each workstation is key. This includes adjustable workstations, proper tool selection, and breaks to allow workers to rest and stretch. Monitoring worker fatigue levels and providing necessary breaks can prevent errors and ensure productivity throughout the shift. A study on worker fatigue by the Ergonomics Society showed a direct correlation between reduced fatigue and increased efficiency.

Implementing Lean Manufacturing Principles

Lean manufacturing principles are instrumental in minimizing waste and maximizing efficiency in furniture assembly.

- Eliminating Waste: Lean manufacturing focuses on identifying and eliminating waste in all aspects of the production process. This includes eliminating unnecessary steps, reducing material waste, and optimizing inventory management. By applying the five wastes (muda): transport, inventory, motion, waiting, overproduction, overprocessing, defects, and extra-processing, furniture factories can significantly reduce costs and improve efficiency.

Quality Control & Inspection

Implementing robust quality control is crucial for furniture factories to maintain high standards, minimize defects, and enhance customer satisfaction. A well-structured quality control system ensures consistent product quality, reduces rework, and streamlines production processes. This section details the process of implementing such a system, highlighting technological advancements and the importance of standardized procedures.

Establishing a Robust Quality Control System

A robust quality control system in furniture factories involves a multi-faceted approach encompassing pre-production planning, in-process monitoring, and post-production inspection. Clear quality standards and procedures need to be documented and communicated to all personnel involved in the production chain. This ensures everyone understands the expectations for quality at each stage. The system should include defined roles and responsibilities for quality control personnel.

These personnel need to be adequately trained to perform inspections and identify defects effectively. Furthermore, the system should include a mechanism for tracking and analyzing defects, enabling identification of recurring issues and the implementation of corrective actions.

Utilizing Technology for Enhanced Quality Control

Technology plays a significant role in enhancing the accuracy and speed of quality control processes. 3D scanning, for instance, allows for precise measurements and comparisons against design specifications, identifying discrepancies early in the process. Automated inspection systems can quickly evaluate multiple parameters simultaneously, such as dimensions, material consistency, and surface finish. This significantly reduces the time spent on manual inspections and increases the overall efficiency of the quality control process.

Automated systems can also record data, facilitating analysis and identifying trends in defects.

Importance of Standardized Inspection Procedures

Standardized inspection procedures are vital for maintaining consistent quality and efficiency. These procedures detail the specific steps, criteria, and tolerances for each inspection point. A clear checklist or guide should be available to all inspectors, ensuring uniformity in the inspection process. The use of standardized procedures reduces variability, making it easier to identify inconsistencies and implement corrective actions.

This also provides a basis for comparison across different production runs and locations.

Preventing Defects and Rework

Preventing defects and rework is more cost-effective than rectifying them. Several strategies can be employed during the production process. Firstly, rigorous material inspection and quality checks before the production process begin. This ensures that only high-quality materials are used. Regular training and refresher courses for production staff on quality standards can improve their awareness and ability to recognize potential defects early.

Using quality control tools, such as process control charts and Pareto analysis, can help identify and analyze patterns of defects. This allows for the implementation of preventative measures at the source of the problem. Additionally, clear communication channels between different departments, such as design, production, and quality control, help to identify and address potential issues early in the process.

These preventive measures will ultimately minimize rework and ensure a higher yield of high-quality products.

Technology Integration & Automation

Integrating advanced technologies like robotics and AI is crucial for enhancing efficiency in furniture factories. This involves automating tasks, optimizing processes, and improving data management to achieve greater output with reduced human error. The strategic implementation of these technologies can significantly improve profitability and competitiveness in the furniture industry.

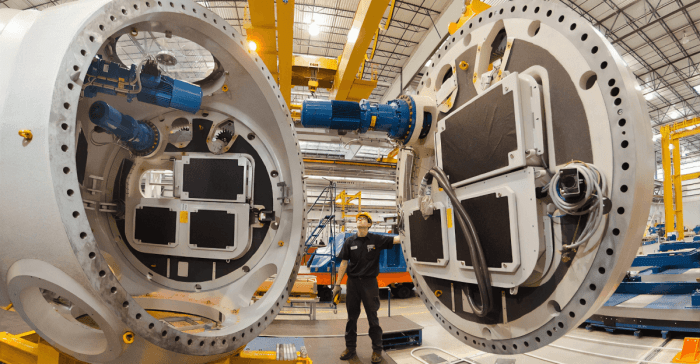

Robotics in Furniture Production

Implementing robotic arms in various stages of furniture production offers significant advantages. Automated tasks like cutting, assembling, and finishing can enhance precision, reduce errors, and boost productivity. For instance, robotic arms equipped with laser cutters can precisely cut wood panels for intricate designs, minimizing material waste and increasing accuracy. Furthermore, robots can handle repetitive tasks, freeing up human workers for more complex and creative endeavors.

AI in Furniture Design and Manufacturing

Artificial intelligence (AI) plays a vital role in streamlining the design and manufacturing processes. AI-powered software can analyze customer preferences and design trends, leading to more customized and marketable products. In the manufacturing phase, AI can optimize production schedules and resource allocation, ensuring efficient workflow and minimizing bottlenecks. Moreover, AI-powered quality control systems can identify defects early in the production process, thereby reducing rework and improving overall product quality.

Benefits and Challenges of Automation

Implementing automation presents several benefits, including increased production speed, improved accuracy, reduced labor costs, and enhanced safety in repetitive tasks. However, challenges such as high initial investment costs, the need for specialized training, and potential job displacement must be carefully considered. It’s essential to have a clear understanding of the specific needs of the furniture factory and choose automation solutions that align with those needs.

The implementation of automation should focus on improving efficiency and productivity, without neglecting the human element of the workforce.

Software Solutions for Process Optimization

Selecting and implementing the right software solutions for managing data and optimizing processes is paramount. This involves choosing software that integrates with existing systems, ensuring data accuracy and consistency, and enabling real-time tracking of production progress. ERP (Enterprise Resource Planning) software is particularly beneficial for managing inventory, orders, and production schedules. Furthermore, specialized software solutions for material handling, quality control, and manufacturing processes can further optimize operations.

The choice of software should be tailored to the specific needs of the factory, taking into account factors such as budget, current infrastructure, and desired level of integration.

Automation Solutions Comparison

The following table contrasts the costs and benefits of various automation solutions for furniture factories. It provides a comparative overview to aid in informed decision-making regarding the most suitable automation approach.

| Automation Solution | Cost | Benefits | Challenges |

|---|---|---|---|

| Robotic Welding | High | Increased accuracy, reduced labor costs, enhanced safety | High initial investment, specialized training required |

| Automated Assembly Lines | Medium | Improved production speed, reduced errors | Integration with existing systems, potential job displacement |

| AI-powered Design Software | Medium | Improved product design, increased customer satisfaction | Requires specialized training, potential compatibility issues |

| Material Handling Robots | High | Increased efficiency, reduced material handling time | High initial investment, potential disruption of existing workflow |

Employee Training & Skill Development

Investing in employee training is crucial for boosting efficiency in furniture factories. Well-trained employees are more productive, adept at handling new technologies, and contribute to a more positive work environment. Comprehensive training programs can translate into significant gains in output and quality, leading to enhanced profitability.Effective employee training goes beyond simply teaching the basics. It requires a structured approach that addresses individual needs, keeps pace with technological advancements, and fosters a culture of continuous improvement.

This approach is essential for adapting to changing market demands and maintaining a competitive edge.

Importance of Comprehensive Training

A comprehensive training program is vital for ensuring that employees possess the necessary skills and knowledge to perform their tasks effectively and efficiently. This training should cover both fundamental manufacturing processes and emerging technologies. It allows for improved adherence to safety protocols, increased output, and enhanced quality control. Employees who receive adequate training are more likely to identify and address potential issues proactively, reducing downtime and errors.

Training Methods and Programs

Various training methods can be employed to enhance employee skills and knowledge. On-the-job training provides practical experience and immediate application of learned skills, often in conjunction with mentoring from experienced colleagues. Classroom-based training allows for structured learning, group discussions, and the sharing of best practices. Simulations and workshops can provide hands-on experience with new technologies and procedures in a safe and controlled environment.

Online learning platforms offer flexible and accessible training options, catering to diverse learning styles and schedules. A blended approach, combining different methods, often yields the most effective results.

Creating a Supportive and Engaging Work Environment

A supportive and engaging work environment is essential for motivating employees and maximizing productivity. Open communication channels, opportunities for feedback, and recognition for achievements foster a sense of belonging and value. Promoting teamwork and collaboration encourages knowledge sharing and the development of problem-solving skills. Regular performance evaluations, coupled with constructive feedback, can help employees identify areas for improvement and tailor their training to their specific needs.

Providing opportunities for professional growth, such as leadership training or cross-functional assignments, further motivates employees and fosters loyalty.

Identifying and Addressing Training Needs

Identifying and addressing training needs is a crucial aspect of improving efficiency. Regular performance evaluations and feedback sessions from supervisors and colleagues can pinpoint areas where employees require additional support. Analyzing production data, identifying bottlenecks, and evaluating error rates can reveal specific skill gaps within the workforce. Conducting surveys and focus groups can provide valuable insights into employee perceptions of their training needs and suggest improvements to existing programs.

This data-driven approach ensures that training programs are targeted and effective, leading to measurable improvements in productivity and efficiency.

Supply Chain Management

Optimizing the supply chain is crucial for furniture factories to maintain competitiveness and profitability. A streamlined supply chain ensures timely material delivery, reduces production bottlenecks, and ultimately, contributes to customer satisfaction. Effective management of this critical function is vital for maintaining a robust and responsive operation.

Strategies for Optimizing the Supply Chain

Furniture factories can employ various strategies to optimize their supply chain, starting from the initial sourcing of materials to the final delivery of the finished product. Proactive planning and strong supplier relationships are key to this process.

- Sourcing Strategies: Selecting reliable suppliers who adhere to quality standards and deliver materials on time is paramount. Evaluating supplier performance metrics like on-time delivery rates and defect rates helps in making informed decisions. Diversifying sourcing from multiple suppliers reduces reliance on a single source, mitigating risks associated with disruptions. Negotiating favorable contracts with suppliers can also lead to cost savings.

- Inventory Management: Maintaining optimal inventory levels is essential. Excess inventory ties up capital, while insufficient stock can halt production. Implementing inventory management systems, such as just-in-time (JIT) inventory, can minimize storage costs and improve efficiency. Utilizing forecasting models based on historical sales data can help predict demand and optimize inventory levels. A balance must be struck between the need for readily available materials and the costs of overstocking.

- Transportation and Logistics: Efficient transportation and logistics play a critical role in minimizing lead times. Selecting appropriate transportation modes, such as trucking or rail, considering factors like cost, speed, and reliability is important. Optimizing routes and utilizing advanced logistics software can streamline the movement of materials and finished products. Utilizing real-time tracking systems can improve visibility and responsiveness to potential delays.

- Delivery Optimization: Improving delivery processes, such as implementing efficient order fulfillment systems and optimizing delivery routes, can minimize lead times and improve customer satisfaction. Implementing clear communication channels between the factory and delivery services can facilitate seamless coordination. Collaboration with delivery partners to develop efficient delivery schedules and strategies is critical.

Methods for Reducing Lead Times

Minimizing lead times is vital for furniture factories to meet customer demands and maintain a competitive edge. A streamlined process reduces overall production costs and improves profitability.

- Supplier Collaboration: Developing close relationships with suppliers enables proactive communication about potential delays and facilitates joint problem-solving. Early communication and coordination are essential. Sharing production schedules with suppliers allows them to anticipate demand and optimize their own processes.

- Improved Communication: Implementing effective communication channels across the supply chain fosters collaboration. Utilizing technology, such as shared online platforms or project management software, facilitates transparent communication between different departments and suppliers. Clear communication about production schedules, material availability, and potential delays minimizes disruptions and keeps all stakeholders informed.

- Lean Manufacturing Principles: Implementing lean manufacturing principles, such as eliminating waste and streamlining processes, can significantly reduce lead times. Analyzing and identifying bottlenecks in the supply chain and addressing them effectively is essential. This includes streamlining material handling, reducing order processing time, and enhancing communication protocols.

- Technological Advancements: Utilizing technology, such as advanced forecasting software or real-time tracking systems, can enhance visibility and responsiveness to potential disruptions. Utilizing these technologies can help predict demand and optimize inventory levels, reducing lead times. Integrating these tools can lead to better control over the entire supply chain.

Building Strong Relationships with Suppliers and Distributors

Strong relationships with suppliers and distributors are crucial for a successful supply chain. This fosters mutual trust and understanding, improving communication and collaboration.

- Open Communication: Maintaining open lines of communication fosters mutual trust and understanding. This includes regular communication, addressing concerns promptly, and celebrating successes together. Regular meetings, progress reports, and feedback sessions are crucial.

- Mutual Benefits: Focusing on mutually beneficial outcomes encourages long-term partnerships. This means considering the needs of both parties and ensuring that the agreement is fair to both. This includes understanding each other’s business priorities.

- Joint Problem Solving: Collaborating on problem-solving builds trust and enhances the relationship. Working together to identify and address challenges proactively helps both parties to overcome obstacles efficiently.

- Performance Monitoring: Tracking supplier performance metrics helps identify areas for improvement. This includes on-time delivery, quality of materials, and responsiveness to requests. Regular evaluations can ensure the supplier continues to meet expectations.

Improving Communication and Collaboration

Effective communication and collaboration across the supply chain are vital for success. This includes the sharing of information and working together towards common goals.

- Shared Platforms: Using shared online platforms or project management software improves communication and collaboration across different stages of the supply chain. This allows all stakeholders to access and update information in real-time, ensuring transparency and efficiency.

- Regular Meetings: Regular meetings between the factory and its suppliers, distributors, and other stakeholders facilitate open communication and collaboration. These meetings provide a platform for sharing updates, addressing concerns, and coordinating activities. The meetings should be focused on productive discussions and actionable results.

- Standardized Processes: Implementing standardized processes and procedures across the supply chain streamlines operations. This ensures everyone is on the same page, minimizing confusion and improving efficiency. Standardization ensures a smooth flow of information and materials.

- Feedback Mechanisms: Implementing effective feedback mechanisms allows stakeholders to provide input and suggestions for improvement. This includes regular surveys, feedback forms, and open forums for discussions. This feedback loop is crucial for identifying and addressing issues promptly.

Waste Reduction & Sustainability

Source: accountingprofessor.org

Minimizing waste and adopting sustainable practices are crucial for furniture factories seeking long-term profitability and a positive environmental footprint. By embracing these principles, companies can reduce their environmental impact, enhance their brand image, and potentially unlock significant cost savings. This section details strategies to achieve these goals.Adopting sustainable practices is no longer a luxury but a necessity for businesses aiming for long-term success.

Furniture production, with its inherent resource consumption, presents unique opportunities for waste reduction. By strategically implementing sustainable practices, factories can improve operational efficiency, lower costs, and enhance their brand reputation.

Material Waste Minimization

Effective material waste minimization begins with meticulous planning and inventory management. Detailed material requirements planning (MRP) systems ensure accurate estimations, minimizing material over-ordering and subsequent waste. Optimized cutting techniques, such as laser cutting and computer-aided design (CAD) software, drastically reduce material scrap. Implementing a comprehensive inventory management system allows for real-time tracking and reduces material obsolescence.

Energy Consumption Reduction

Reducing energy consumption in furniture factories involves multifaceted strategies. Energy-efficient machinery and lighting fixtures are vital. Implementing smart building automation systems allows for optimized energy usage. Furthermore, meticulous process optimization can identify areas for energy savings in the manufacturing process. For example, optimizing drying and curing times for materials can reduce energy expenditure.

Recycling and Reuse Strategies

Implementing robust recycling programs for wood scraps, metal components, and other materials is paramount. Partnering with recycling facilities specializing in furniture industry waste streams can ensure proper disposal and material recovery. Reusing materials in new furniture designs, such as repurposing wood scraps into decorative elements, not only reduces waste but also introduces innovative design elements. Furthermore, considering the use of reclaimed wood or recycled plastics can provide a cost-effective and environmentally friendly alternative.

Sustainable Materials and Practices

Utilizing sustainable materials, like bamboo, reclaimed wood, or responsibly sourced wood, can significantly reduce the environmental impact. Implementing eco-friendly paints and finishes minimizes the use of harmful chemicals. Adopting circular economy principles, such as designing products for disassembly and reuse, ensures a closed-loop system.

Economic Benefits of Sustainable Practices

The economic benefits of adopting sustainable practices extend beyond the environmental impact. A strong reputation for environmental responsibility can attract environmentally conscious consumers and investors. Moreover, reduced material waste and energy consumption translate into cost savings. Efficient resource management and waste minimization contribute to lower operating expenses. Furthermore, compliance with environmental regulations and avoiding penalties is a significant economic advantage.

For instance, companies that successfully implement waste reduction strategies and comply with environmental regulations are often rewarded with favorable business licenses and reduced regulatory costs.

Last Recap

Source: 4industry.com

In conclusion, achieving greater efficiency in furniture factories requires a multifaceted approach. By focusing on optimizing production planning, material handling, assembly processes, quality control, technology integration, employee training, supply chain management, and waste reduction, furniture manufacturers can enhance their competitiveness and sustainability. This guide has presented a comprehensive overview of these key areas, providing actionable insights to help furniture factories thrive in a demanding market.

Frequently Asked Questions

What are some common challenges in implementing automation in furniture factories?

Implementing automation in furniture factories can present challenges related to initial investment costs, the need for specialized training for employees, and potential disruptions to existing workflows. Careful planning and a phased approach can help mitigate these difficulties.

How can furniture factories reduce material waste?

Reducing material waste involves optimizing material usage during production, implementing precise cutting techniques, and exploring strategies for recycling and reusing leftover materials. A strong emphasis on minimizing waste can be environmentally friendly and financially beneficial.

What are the key benefits of using production scheduling software?

Production scheduling software can enhance efficiency by optimizing production schedules, forecasting demand accurately, and providing real-time tracking of production progress. This leads to reduced bottlenecks, minimized delays, and maximized output.