Global Supply Chain Shifts and Their Impact on Furniture Manufacturing in 2025 presents a critical look at the evolving landscape of furniture production. The shifts in global supply chains, driven by various factors like geopolitical events and the pandemic, are reshaping the entire industry. This analysis delves into the challenges and opportunities facing furniture manufacturers, exploring alternative material sourcing, innovative production strategies, and adapting to changing consumer preferences in the face of these disruptions.

The future of furniture manufacturing is being reshaped, and understanding these shifts is crucial for navigating this new era.

This report will examine the intricate interplay between global supply chain dynamics and the furniture manufacturing sector in 2025. We’ll dissect the specific challenges manufacturers face, from sourcing materials to adapting production processes. The discussion will cover alternative materials, resilient production strategies, and how the market is evolving to meet changing consumer demands. Ultimately, this report aims to provide a comprehensive understanding of the potential impact of these shifts on the future of furniture manufacturing.

Introduction to Global Supply Chain Shifts

Source: commercialinteriordesign.com

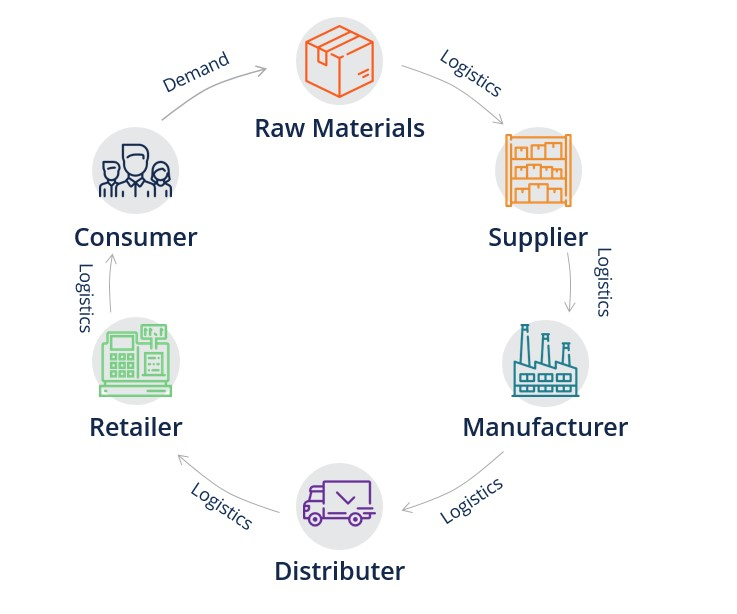

Global supply chains are undergoing a period of significant transformation, driven by a confluence of factors. The traditional, often linear, models are giving way to more complex, multifaceted systems. This evolution impacts not just individual businesses but the global economy as a whole. The shifting landscape requires careful consideration and adaptation to maintain competitiveness and resilience.

Current Global Supply Chain Dynamics

The current global supply chain landscape is characterized by increased volatility and uncertainty. Disruptions, such as those stemming from geopolitical tensions and natural disasters, are becoming more frequent and impactful. Supply chain bottlenecks, often exacerbated by pandemic-related disruptions, continue to affect businesses across various sectors. This instability is forcing companies to reassess their strategies and adopt more agile and resilient approaches.

Key Factors Driving Supply Chain Shifts, Global Supply Chain Shifts and Their Impact on Furniture Manufacturing in 2025

Several key factors are driving the current shifts in global supply chains. Geopolitical tensions, including trade wars and sanctions, are creating significant obstacles for businesses reliant on international trade. The pandemic profoundly disrupted supply chains, exposing vulnerabilities and highlighting the need for diversification and resilience. Technological advancements, while offering opportunities, also bring about new complexities in managing and coordinating global operations.

Potential Long-Term Consequences on Industries

The evolving global supply chain dynamics will have significant long-term consequences for various industries. Furniture manufacturing, for example, heavily reliant on raw materials and components from multiple countries, will face challenges adapting to new logistical requirements. The increased cost of transportation and potential tariffs could impact pricing and profitability. Businesses will need to adjust their strategies to mitigate these challenges and maintain competitiveness.

Comparison of Pre-Shift and Post-Shift Supply Chain Models

| Characteristic | Pre-Shift Model | Post-Shift Model |

|---|---|---|

| Geographic Focus | Primarily concentrated in specific regions (e.g., East Asia for manufacturing). | Diversified geographically, aiming for regionalization and resilience. |

| Flexibility | Less flexible and adaptable to changing circumstances. | More agile and adaptable to disruptions and changing demands. |

| Risk Management | Limited risk mitigation strategies, often relying on single-source suppliers. | Proactive risk management through diversification of suppliers, and inventory strategies. |

| Technology Integration | Limited use of technology for supply chain optimization. | Extensive use of technology, including AI, data analytics, and automation. |

| Cost Structure | Lower initial costs, but higher vulnerability to disruptions. | Potentially higher initial costs, but lower long-term risk and more stable supply chain. |

Impact on Furniture Manufacturing

The global supply chain has undergone significant shifts in recent years, impacting various industries, including furniture manufacturing. These changes have introduced new complexities and challenges for companies seeking to maintain production efficiency and competitiveness. This section will explore the specific difficulties faced by furniture manufacturers, examine evolving material availability, and discuss the broader implications for design, cost, and production timelines.The furniture industry, historically reliant on established global supply chains, now faces a new reality characterized by unpredictable disruptions and fluctuating costs.

Manufacturers must adapt to these dynamic conditions, or risk losing market share and profitability.

Material Sourcing and Availability

The availability of raw materials has become increasingly volatile. Delays in shipping, port congestion, and geopolitical instability have created bottlenecks in the supply of crucial materials like wood, metal, and textiles. This volatility has led to price fluctuations and unpredictable lead times, forcing manufacturers to diversify sourcing strategies and explore alternative materials. For example, some companies are now incorporating recycled materials or sustainable alternatives to reduce reliance on traditional, potentially volatile sources.

Impact on Production Costs and Timelines

Supply chain disruptions have significantly increased production costs. Manufacturers face higher transportation costs, inflated material prices, and potential labor shortages, all contributing to a rise in the final cost of furniture. Lead times for production have also extended considerably, impacting delivery schedules and potentially jeopardizing customer satisfaction. The increased costs often translate to higher prices for consumers, impacting the affordability of furniture.

Impact on Furniture Design and Customization Options

The evolving supply chain has influenced furniture design and customization options. Manufacturers are now more inclined to create designs using readily available and predictable materials. This can limit the range of styles and finishes available, particularly for highly customized pieces. However, some manufacturers are exploring modular furniture designs, which can be easily reconfigured using readily available components.

This strategy offers a degree of flexibility in customization despite limitations in materials.

Innovative Strategies to Mitigate Supply Chain Disruptions

Furniture manufacturers are employing various innovative strategies to mitigate supply chain disruptions. These include diversifying material sourcing to multiple regions, establishing closer relationships with suppliers, and implementing just-in-time inventory management systems. Some are also investing in advanced logistics and tracking technologies to better monitor and manage their supply chains.

Table: Impact on Different Furniture Types

| Furniture Type | Extent of Impact | Explanation |

|---|---|---|

| Custom-designed furniture | High | Customization often requires specific materials that may be harder to acquire, leading to delays and higher costs. |

| Mass-produced furniture | Moderate | While mass-produced furniture is not as dependent on individual material specifications, fluctuating material prices and transportation costs still impact profitability. |

| Modular furniture | Moderate to Low | Modular designs can adapt to supply chain fluctuations more easily by utilizing readily available components. |

| Furniture with unique finishes | High | Specific finishes or coatings may face supply chain disruptions, impacting availability and potentially raising costs. |

Material Sourcing Alternatives

Furniture manufacturers are increasingly seeking alternative material sourcing strategies to mitigate supply chain disruptions and environmental concerns. This involves a shift away from reliance on global sources towards more localized and sustainable options. Understanding the advantages and disadvantages of these approaches is crucial for long-term viability and profitability.

Alternative Material Sourcing Strategies

Furniture manufacturers are exploring diverse strategies to reduce their reliance on distant suppliers. This includes developing closer relationships with local and regional producers, exploring the use of recycled and reclaimed materials, and investigating innovative sustainable materials. A strategic approach that considers both cost-effectiveness and environmental impact is vital.

Local and Regional Materials

Utilizing locally or regionally sourced materials can offer several benefits. Reduced transportation costs and emissions are significant advantages. Stronger relationships with local suppliers may lead to more stable and predictable supply chains, which is a critical element in mitigating supply chain risks. However, the availability and quality of materials may be limited in some regions, and potential price fluctuations within the local market need to be considered.

Furthermore, stringent regulations regarding sourcing may vary across regions, necessitating compliance procedures.

Sustainable Material Options

A growing number of manufacturers are incorporating sustainable materials into their products. These materials often exhibit superior environmental profiles, such as reduced carbon footprint, lower water consumption, and reduced chemical usage. Examples include bamboo, cork, and mycelium, which offer attractive alternatives to traditional materials like wood. The availability of these materials and their suitability for specific furniture designs require careful consideration.

Recycled and Reclaimed Materials

Recycled and reclaimed materials offer a valuable avenue for reducing waste and promoting circularity. These materials can be a cost-effective alternative to virgin materials, and their use contributes to a more sustainable production process. Furthermore, they often display unique characteristics and aesthetic qualities, allowing for the creation of distinctive furniture pieces. However, the consistency and availability of recycled materials may present challenges.

Cost-Effectiveness Comparison

The cost-effectiveness of various material sourcing strategies varies significantly. While local materials might have a lower transportation cost, the cost of the raw material itself may differ. Sustainable materials might have a higher initial cost compared to traditional materials. Factors such as material availability, processing costs, and market fluctuations must be carefully evaluated to optimize cost-effectiveness.

Sustainable Material Options for Furniture Types

| Furniture Type | Sustainable Material Options | Suitability |

|---|---|---|

| Dining Tables | Bamboo, reclaimed wood, cork | Excellent for contemporary designs; requires careful selection for durability |

| Sofas | Recycled textiles, mycelium, linen | Excellent for environmentally conscious designs; needs robust testing for comfort and durability |

| Beds | Bamboo, reclaimed wood, recycled steel | Suitable for modern and minimalist designs; may require specific bed frame designs |

| Chairs | Recycled plastic, mycelium, bamboo | Good for both contemporary and traditional styles; durability depends on the material |

Production Strategies and Logistics: Global Supply Chain Shifts And Their Impact On Furniture Manufacturing In 2025

Source: architectandinteriorsindia.com

Furniture manufacturers are facing a complex landscape in 2025, with shifting global supply chains impacting production and logistics. Adapting to these changes necessitates innovative strategies for sourcing materials, managing inventory, and optimizing transportation. Successful companies will be those that embrace flexibility, resilience, and a forward-thinking approach to their manufacturing processes.

New Production Strategies

The evolving supply chain necessitates new production strategies. Manufacturers are moving away from traditional, rigid models toward more agile and responsive systems. This includes diversifying supplier networks, reducing reliance on single sources, and adopting more flexible production schedules. Just-in-time inventory management is becoming crucial to minimizing storage costs and waste, while embracing lean manufacturing principles can optimize efficiency and reduce operational expenses.

This adaptability is key to weathering supply chain disruptions and maintaining profitability.

Impact on Manufacturing Processes and Technologies

The shift in supply chains has driven significant changes in manufacturing processes and technologies. Automation is increasingly important to maintain output and efficiency. Robotic process automation (RPA) and advanced machine learning algorithms are being utilized to streamline tasks and reduce human error. The rise of 3D printing and additive manufacturing offers opportunities for localized production and customized furniture designs.

Furthermore, data analytics plays a vital role in monitoring supply chain performance, identifying potential bottlenecks, and proactively addressing disruptions.

Comparison of Manufacturing Approaches

Different manufacturing approaches are being evaluated in light of the evolving supply chain. Traditional just-in-time (JIT) approaches, while effective in stable environments, are now being complemented by strategies that prioritize safety stock and diversified sourcing. Lean manufacturing principles, focused on minimizing waste and maximizing efficiency, are still valuable, but require adaptation to account for fluctuating material availability and transportation costs.

A blend of strategies, incorporating elements of both JIT and lean manufacturing, is often the most effective approach for furniture manufacturers.

Importance of Flexible and Resilient Production Processes

Flexibility and resilience are critical for navigating the uncertain future of global supply chains. Furniture manufacturers are implementing strategies that enable them to quickly adjust production to changes in demand, material availability, or transportation disruptions. This often involves establishing backup supplier relationships and developing contingency plans for material sourcing. Companies investing in flexible production processes are better positioned to adapt to disruptions and maintain a consistent supply of goods.

Logistics Strategies for Furniture Manufacturers

A well-defined logistics strategy is crucial for efficient delivery and cost management. Furniture manufacturers need to consider various factors, including transportation modes, warehousing solutions, and inventory management systems.

| Logistics Strategy | Description | Effectiveness |

|---|---|---|

| Multimodal Transportation | Utilizing a combination of transportation modes (e.g., sea, rail, air) to optimize cost and transit time. | High effectiveness when optimizing transit time and cost for long-distance shipments. |

| Optimized Warehousing | Strategic use of warehouses to consolidate shipments, manage inventory, and reduce transportation costs. | High effectiveness when streamlining the movement of inventory through warehouses, allowing for efficient storage and delivery. |

| Real-Time Tracking | Implementing systems for real-time tracking of shipments to monitor progress and address potential delays. | High effectiveness when providing visibility and control over shipments, allowing for proactive intervention and problem resolution. |

| Supplier Relationship Management | Developing strong relationships with suppliers to ensure timely delivery of materials and maintain flexibility in sourcing. | High effectiveness when establishing alternative sources and improving supply chain resilience. |

| Inventory Management Optimization | Implementing systems for effective inventory management, balancing costs and minimizing stockouts. | High effectiveness when maintaining optimal inventory levels to avoid shortages and overstocking. |

Market Adaptation and Consumer Behaviour

The shifting global supply chain is profoundly impacting furniture manufacturing, forcing companies to adapt to new realities in sourcing, production, and logistics. This necessitates a keen understanding of evolving consumer preferences and market trends. Manufacturers must anticipate how these changes will affect consumer behavior and adjust their offerings accordingly.Adapting to these changes involves more than just reacting to market shifts; it requires a proactive approach to anticipate future trends and tailor products to meet those needs.

This proactive stance enables manufacturers to stay ahead of the curve, ensuring sustained profitability and market share.

Impact of Supply Chain Shifts on Furniture Market Trends

Supply chain disruptions have influenced market trends, driving consumers towards alternative materials, shorter lead times, and more localized production. The increasing cost of imported materials and transportation has prompted consumers to seek locally sourced options and reduced shipping times, favouring domestic manufacturers. This shift in demand necessitates a careful evaluation of existing supply chains and a potential re-alignment with local suppliers.

Evolving Consumer Preferences Regarding Furniture

Consumers are increasingly seeking furniture that reflects their individual lifestyles and values. This includes a strong emphasis on sustainability, functionality, and aesthetics. A growing demand for modular, multi-functional furniture pieces is also noticeable. The rising popularity of minimalist designs and eco-friendly materials signals a desire for both aesthetic appeal and environmental consciousness.

Importance of Customization and Personalization

Customization and personalization are becoming key factors in furniture sales. Consumers are looking for unique and tailored pieces that reflect their personal style and needs. Manufacturers can leverage technology and design flexibility to offer greater customization options, catering to a wider range of tastes and preferences. This personalized approach can help to differentiate products and create a stronger brand identity.

How Manufacturers Can Adapt Their Offerings to Meet Evolving Demands

Manufacturers can adapt by exploring new materials, implementing agile production processes, and embracing digital design tools. They should prioritize flexibility in their production lines to quickly respond to evolving customer preferences. Collaboration with design experts and online platforms can further enhance the customization capabilities and create a seamless customer experience.

Challenges and Opportunities Presented by E-Commerce in Furniture Sales

E-commerce presents both challenges and opportunities for furniture manufacturers. The challenge lies in showcasing products effectively in a virtual environment, requiring high-quality imagery and detailed product descriptions. Opportunities include wider market reach, direct customer interaction, and potential for personalized recommendations. Effective online marketing strategies are crucial to success in this digital marketplace.

Table: Evolving Consumer Preferences and Manufacturer Responses

| Evolving Consumer Preference | Manufacturer Response |

|---|---|

| Sustainability and Eco-Friendly Materials | Explore alternative, sustainable materials; highlight eco-friendly manufacturing processes; emphasize recycled or reclaimed components |

| Customization and Personalization | Offer online design tools; provide modular furniture options; allow for bespoke customization; provide ample options in materials, colours, and finishes. |

| Functionality and Multi-functionality | Develop furniture with multiple uses; offer modular pieces that can adapt to changing needs; emphasize space-saving designs |

| Local Sourcing and Shorter Lead Times | Partner with local suppliers; optimize logistics for faster delivery; focus on regional or national production |

| Minimalist Designs | Emphasize clean lines and simple aesthetics; focus on high-quality materials with a minimalist approach; provide clear product descriptions and detailed imagery |

Technological Solutions for Resilience

The evolving global landscape necessitates proactive strategies for furniture manufacturers to navigate supply chain disruptions. Embracing technological advancements is crucial for enhancing resilience, mitigating risks, and optimizing operational efficiency. Leveraging data analytics, automation, and blockchain technology can bolster supply chain transparency and responsiveness.Technological advancements offer furniture manufacturers the tools to anticipate and adapt to shifting supply chains. Data-driven insights can predict potential bottlenecks and optimize resource allocation.

Automation can improve production efficiency and reduce reliance on human labor, while blockchain technology can establish trust and transparency throughout the entire supply chain. Implementing these strategies allows manufacturers to become more adaptable and resilient in the face of future uncertainties.

Data Analytics and AI for Risk Prediction

Data analytics and artificial intelligence (AI) play a vital role in predicting and mitigating supply chain risks. Sophisticated algorithms can analyze vast datasets, including historical sales figures, material prices, and shipping times, to identify patterns and anomalies. This analysis enables manufacturers to anticipate potential disruptions, such as material shortages or transportation delays, and implement proactive measures to avoid negative consequences.

For instance, by analyzing historical data on raw material availability and market trends, manufacturers can proactively secure alternative suppliers and adjust production plans.

Automation in Furniture Manufacturing

Automation is transforming furniture manufacturing, improving efficiency and reducing reliance on human labor. Robotic process automation (RPA) and computer vision systems are employed for tasks such as cutting, assembling, and finishing furniture components. This increases production speed, reduces errors, and improves consistency. Furthermore, automated systems can adapt to changing production demands, allowing manufacturers to scale up or down operations more rapidly in response to market fluctuations.

For example, automated assembly lines in furniture factories are becoming increasingly common, enabling higher production rates and better quality control.

Blockchain for Supply Chain Transparency

Blockchain technology enhances supply chain transparency by creating a secure and immutable record of transactions. This allows manufacturers to track materials from origin to final product, ensuring ethical sourcing and reducing the risk of counterfeit goods. For instance, a furniture manufacturer can use blockchain to verify the origin of wood used in its products, ensuring it complies with sustainable forestry practices.

This traceability is valuable in building consumer trust and maintaining a positive brand image.

Digital Tools for Operational Optimization

Digital tools empower manufacturers to optimize their operations and enhance responsiveness to changing conditions. Enterprise resource planning (ERP) systems, for example, integrate various aspects of the business, from inventory management to production scheduling. This allows for real-time visibility into inventory levels, enabling more efficient order fulfillment and reduced lead times. Furthermore, digital tools can streamline communication and collaboration among different stakeholders in the supply chain, fostering greater efficiency and responsiveness to disruptions.

Potential Benefits of Technological Solutions

“Implementing these technologies can lead to significant improvements in supply chain resilience, allowing furniture manufacturers to adapt to disruptions more quickly and efficiently. This can also translate into enhanced profitability and a stronger competitive position in the market.”

- Data Analytics and AI: Improved forecasting accuracy, proactive risk mitigation, and optimized resource allocation.

- Automation: Increased production efficiency, reduced labor costs, and enhanced quality control.

- Blockchain: Enhanced supply chain transparency, improved ethical sourcing, and reduced risk of counterfeiting.

- Digital Tools: Streamlined operations, real-time visibility into inventory, and improved communication & collaboration.

Government Policies and Regulations

Government policies and regulations play a crucial role in shaping the furniture manufacturing landscape. These policies can either foster growth and resilience or hinder innovation and competitiveness. Understanding the interplay between government actions and industry trends is vital for anticipating future challenges and opportunities.Government regulations often dictate permissible materials, manufacturing processes, and disposal procedures. These stipulations, while aimed at various societal goals like environmental protection and worker safety, can influence production costs and timelines.

Trade agreements and tariffs further complicate the picture, as they impact import/export dynamics, affecting both input costs and finished product pricing.

Impact of Trade Agreements and Tariffs

Trade agreements, such as the USMCA or EU trade deals, significantly influence the furniture industry. Favorable agreements can reduce tariffs on imported materials, potentially lowering production costs. Conversely, tariffs imposed on furniture imports can raise prices for consumers and negatively affect domestic manufacturers. For instance, a significant tariff on imported wood from a major supplier could increase the cost of raw materials, impacting profit margins and competitiveness.

Potential for Government Incentives

Government incentives can play a critical role in bolstering the furniture manufacturing sector. Tax breaks, grants, or subsidies for research and development in sustainable materials or innovative manufacturing processes could stimulate growth and competitiveness. Subsidies could also help furniture manufacturers transition to more sustainable practices, a growing priority for consumers. For example, tax credits for energy-efficient manufacturing equipment or rebates for the use of recycled materials can encourage industry adoption of sustainable practices.

Importance of Sustainable Regulations

Growing consumer awareness of environmental issues necessitates sustainable regulations in the furniture industry. These regulations can mandate the use of recycled materials, restrict the use of harmful chemicals, or require specific waste management procedures. For instance, regulations requiring the use of recycled wood or banning the use of certain toxic finishes could lead to a shift in sourcing strategies.

Potential Impact of Policies in Furniture Manufacturing

| Policy Area | Potential Impact | Explanation |

|---|---|---|

| Trade Agreements | Lower input costs/higher prices | Favorable agreements reduce tariffs, while tariffs increase prices for consumers and hurt domestic manufacturers. |

| Government Incentives | Increased competitiveness/innovation | Tax breaks, grants, and subsidies can encourage investment in research and development of sustainable practices, potentially boosting industry growth. |

| Sustainable Regulations | Increased costs/environmental responsibility | Regulations mandating recycled materials, limiting harmful chemicals, or requiring specific waste management procedures can increase production costs but also foster environmental responsibility. |

| Environmental Protection Regulations | Higher production costs/improved environmental performance | Regulations that limit harmful emissions or dictate specific waste disposal processes increase production costs, but lead to a better environmental performance. |

Closing Summary

In conclusion, the global supply chain shifts are profoundly impacting the furniture manufacturing industry in 2025. Manufacturers must adapt to new challenges, such as fluctuating material costs and changing consumer preferences, by embracing innovative material sourcing, agile production strategies, and a deep understanding of market trends. Successfully navigating these changes will require a combination of technological advancements, resilient production processes, and a proactive approach to market adaptation.

The future of furniture manufacturing depends on embracing these shifts and capitalizing on the opportunities they present.

Commonly Asked Questions

What are the biggest challenges facing furniture manufacturers due to the pandemic?

The pandemic significantly disrupted supply chains, leading to material shortages and increased costs. Manufacturers struggled to maintain production timelines and faced pressure to adapt to changing consumer preferences.

How are governments responding to these supply chain shifts?

Government responses vary, but some are implementing policies to support domestic industries and promote sustainable practices. Trade agreements and tariffs are also playing a significant role in these shifts.

What role does e-commerce play in the furniture industry’s adaptation?

E-commerce presents both challenges and opportunities. Manufacturers need to adapt their strategies to reach online customers while ensuring efficient delivery and managing potential logistical issues.

What are some examples of sustainable material sourcing strategies?

Exploring recycled and reclaimed materials, and utilizing locally sourced materials are gaining traction as sustainable alternatives. This includes a greater emphasis on the environmental footprint of materials.