Craftsmanship Meets Automation: Balancing Art and Industry in Furniture Manufacturing explores the fascinating intersection of traditional artistry and modern technology in furniture production. This blend of human skill and automated processes presents both challenges and opportunities for the industry. The evolution of craftsmanship, from its historical roots to contemporary interpretations, is examined alongside the rise of automation, including robotics and CNC machines.

The discussion delves into how these seemingly disparate forces can work together, creating furniture that embodies both artistic expression and industrial efficiency.

The report investigates the potential synergies between these two approaches, emphasizing how automation can support and enhance, rather than replace, human craftsmanship. It analyzes the impact on design, aesthetics, and the future of the furniture manufacturing sector, considering innovative approaches, the evolving job market, and sustainability concerns. Real-world case studies of successful integrations illuminate practical applications and strategies for navigating the challenges.

Defining Craftsmanship in the Modern Era

Furniture craftsmanship has a rich history, evolving from simple, functional pieces to intricate works of art. Early examples, often handcrafted by local artisans, showcase the ingenuity and skill of their time. Materials varied widely, reflecting the resources available in different regions and eras, from wood and leather to bone and ivory. Over centuries, techniques like joinery, carving, and inlay developed into sophisticated methods, influencing design and aesthetic across generations.The modern definition of craftsmanship in furniture manufacturing is undergoing a transformation.

While traditional techniques remain highly valued, the integration of advanced manufacturing processes is blurring the lines between handcraft and industrial production. This evolution reflects a broader shift in societal expectations, seeking both quality and efficiency in modern furniture. Craftsmanship today is not just about skill in handwork, but also about understanding materials, design principles, and the use of appropriate tools and technologies to create durable and aesthetically pleasing pieces.

Historical Overview of Furniture Craftsmanship

Furniture craftsmanship boasts a rich history, marked by distinct techniques and materials. Early examples from various cultures often showcased the ingenuity and resourcefulness of the time, using available materials like wood, bone, and ivory. Over time, the complexity of joinery, carving, and inlay increased, shaping the aesthetics and design of furniture across eras. The development of specialized tools further refined these techniques, enabling artisans to produce increasingly elaborate and detailed pieces.

Evolving Definition of Craftsmanship

The definition of “craftsmanship” in contemporary furniture manufacturing is broadening. While traditional hand-crafting methods remain essential, the integration of automated processes allows for increased production volume and efficiency. This blending of traditional skills with modern technologies is a hallmark of contemporary furniture production. Contemporary artisans need to adapt and develop a multifaceted skillset, blending traditional techniques with the capabilities of advanced machinery, leading to a unique form of craftsmanship that values both the human touch and industrial precision.

Values and Principles of High-Quality Craftsmanship

High-quality craftsmanship in furniture manufacturing is defined by several core values and principles. These include meticulous attention to detail, mastery of materials, and a profound understanding of design principles. Furthermore, a commitment to durability and longevity is vital, ensuring the piece withstands the test of time. Craftsmanship also emphasizes sustainability, using eco-friendly materials and production methods. Finally, the personal touch and unique character of each piece are crucial, differentiating it from mass-produced items.

Importance of Human Touch and Skill

The human touch remains indispensable in furniture production, even in an increasingly automated world. The intricate details, the subtle variations in finish, and the unique character of each piece often arise from the skilled hands of the artisan. This human element is a significant differentiator in high-quality furniture, adding a personal touch that goes beyond mere functionality. The careful selection and preparation of materials, the precise execution of joinery, and the artful application of finishes are all hallmarks of human skill.

Comparison of Traditional and Modern Furniture Production

| Technique | Tools | Time | Output |

|---|---|---|---|

| Hand Carving | Chisels, gouges, hand planes | Days to weeks | Unique, bespoke pieces |

| Machine-assisted carving | CNC routers, sanders | Hours to days | High-volume, consistent pieces |

| Traditional joinery (mortise and tenon) | Mallet, chisels, hand saws | Days | Strong, durable, and visually appealing pieces |

| Modern mechanical joinery | Automated fastening systems, robotic arms | Hours | High-volume, consistent joints |

| Hand finishing | Brushes, rags, sandpapers | Days | Unique, high-quality finishes |

| Automated finishing | Spray guns, robotic applicators | Hours | Consistent, high-volume finishes |

This table illustrates the fundamental differences in production methods, highlighting the varying levels of time investment and outputs between traditional and modern techniques. Modern methods often prioritize speed and efficiency, while traditional methods emphasize the individual artisan’s skill and the unique qualities of each piece.

Automation in Furniture Manufacturing

Furniture manufacturing, a blend of artistic craft and industrial precision, is undergoing a significant transformation. Automation is rapidly changing the landscape, offering both exciting opportunities and potential challenges for the industry. The integration of technology is impacting everything from design and material selection to assembly and finishing. Understanding the different types of automation and their implications is key to navigating this evolving environment.

Types of Automation in Furniture Production

Automation in furniture manufacturing encompasses various technologies, each with its own unique applications. Robotic arms, CNC machines, and automated assembly lines are prominent examples, each contributing to increased efficiency and precision.

Benefits of Implementing Automation

Automation in furniture production offers numerous advantages. Improved production speed and output are significant benefits, allowing manufacturers to meet growing market demands. Consistent quality control is another key advantage, minimizing human error and ensuring a high standard of finish. Furthermore, automation can lead to significant cost savings in the long run, although initial investment costs can be substantial.

Drawbacks of Implementing Automation

While automation offers considerable benefits, there are also potential drawbacks. High initial investment costs for the necessary equipment and training can be a hurdle for smaller companies. The need for specialized maintenance and repair personnel adds to operational costs. Job displacement is another critical concern, as some roles may become redundant. Furthermore, the dependence on complex machinery can create vulnerabilities in production if there are disruptions to the supply chain or equipment malfunctions.

Impact on Skills and Roles

Automation is reshaping the skills required in furniture manufacturing. Traditional craftsmanship skills remain valuable, but roles are evolving to encompass operation and maintenance of automated systems. Training and upskilling programs are crucial to adapt to the changing demands of the industry. The emergence of roles like robotic technicians, automation specialists, and data analysts reflects this shift.

Examples of Automated Furniture Manufacturing Processes

Automated processes are being implemented across various stages of furniture manufacturing. Robotic arms are used for precise cutting and shaping of wood components, while CNC machines excel at creating intricate designs. Automated assembly lines streamline the joining of components, increasing efficiency and accuracy. These integrated systems are crucial for achieving high production volumes while maintaining a consistent standard of quality.

Automated Furniture Manufacturing Equipment

| Equipment Type | Function | Advantages | Disadvantages |

|---|---|---|---|

| Robotic Arm | Material handling, cutting, assembly, finishing | High precision, repeatability, reduced human error, increased speed | High initial investment, specialized maintenance required, potential for system failure |

| CNC Router | Precise cutting, shaping, and engraving of materials | High precision, intricate designs, reduced material waste | High initial investment, limited material types, operator training required |

| Automated Assembly Line | Conveying and assembling components in a sequential manner | High speed, efficiency, consistent quality | High initial investment, limited flexibility, potential for bottleneck issues |

| Automated Painting/Finishing Systems | Application of coatings, stains, or finishes | Consistent quality, reduced labor costs, improved efficiency | High initial investment, specialized maintenance, potential for paint defects |

The Intersection of Craftsmanship and Automation: Craftsmanship Meets Automation: Balancing Art And Industry In Furniture Manufacturing

Furniture manufacturing is undergoing a significant transformation, with automation playing an increasingly crucial role. This evolution presents a unique opportunity to explore the interplay between traditional craftsmanship and modern technology. Rather than replacing human skill, automation can serve as a powerful tool to enhance the capabilities of skilled artisans and improve the overall production process.Automation offers a pathway to elevate furniture production by streamlining repetitive tasks, increasing precision, and boosting efficiency.

This approach allows human artisans to focus on the more complex and creative aspects of the design and manufacturing process, such as intricate joinery, artistic embellishments, and the unique aesthetic qualities that set a piece apart. The goal is not to diminish the importance of human touch, but to optimize the entire process, leveraging the strengths of both human ingenuity and technological advancements.

Synergies Between Craftsmanship and Automation, Craftsmanship Meets Automation: Balancing Art and Industry in Furniture Manufacturing

Automation, when effectively integrated, can significantly enhance the precision and efficiency of tasks in furniture manufacturing. Automated systems excel at repetitive tasks like cutting, assembling, and finishing, which frees up skilled artisans to focus on higher-level craftsmanship. For instance, CNC routers can create complex curves and intricate designs with exceptional accuracy, eliminating the potential for human error in these areas.

This allows artisans to concentrate on the artistic nuances of the design and the unique aesthetic touches that differentiate the final product.

Enhancing Human Craftsmanship with Automation

Automated systems can act as powerful assistants to human artisans, allowing them to focus on tasks requiring creativity, intuition, and judgment. For example, automated jig systems can ensure consistent and precise joinery, enabling artisans to concentrate on creating beautiful and structurally sound connections. Further, automated finishing systems can apply coatings evenly and efficiently, reducing the need for manual sanding and finishing steps, thus allowing artisans to dedicate more time to achieving the desired aesthetic finish.

Integration of Human Expertise with Automated Systems

Integrating human expertise with automated systems requires careful planning and a deep understanding of the strengths of both. The key lies in assigning tasks based on the capabilities of each component. Automated systems excel at repetitive and precision-driven tasks, while human artisans are better suited for creative problem-solving, aesthetic judgment, and quality control. This integration should be iterative, with ongoing feedback loops to refine the process and optimize the performance of the combined approach.

For example, a system might automatically assemble the basic frame, but a craftsman would then personally adjust and refine the fit and finish.

Comparing Automated and Craftsmanship-Automation Furniture Production

| Production Method | Quality | Cost | Time |

|---|---|---|---|

| Purely Automated | High precision in repetitive tasks, but potentially lacking in unique artistic flair | Potentially lower initial cost due to reduced labor, but higher upfront investment in automation | Faster production time for standardized pieces |

| Craftsmanship & Automation | High quality, combining precision and artistic expression | Potentially higher cost than purely automated, but cost-effective in the long run | Balanced production time, depending on the complexity of the piece |

Improving Efficiency and Precision

Automation can significantly enhance efficiency and precision in furniture production. Automated systems can work continuously, 24/7, minimizing downtime and maximizing output. Furthermore, automation eliminates human error in tasks like cutting, drilling, and assembly, resulting in consistent quality and reducing rework. This improvement in efficiency is especially noticeable in mass production or high-volume orders.

The Future of Furniture Manufacturing

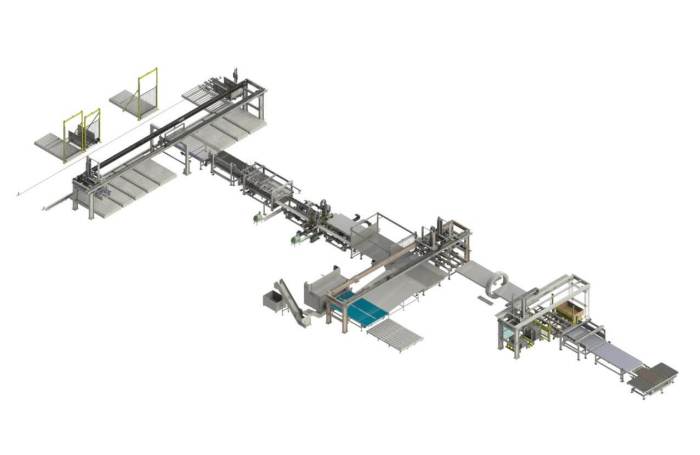

Source: kraft-group.com

The furniture industry is poised for significant transformation as automation and craftsmanship converge. The evolution will be driven by consumer demand for customized, high-quality products, coupled with the need for more efficient and sustainable manufacturing processes. This intersection of art and industry will reshape the landscape of furniture production, offering both challenges and opportunities for the future.The future of furniture manufacturing will see a dynamic interplay between human skill and technological advancement.

This fusion will not replace the artistry of skilled craftsmen, but rather empower them with tools to create unique and innovative pieces. Automation will streamline repetitive tasks, freeing up human labor for more creative and complex aspects of the design and production process.

Likely Evolution of Furniture Manufacturing

The industry will move towards more personalized and customized furniture. Expect a rise in on-demand manufacturing, allowing customers to design and order pieces tailored to their specific needs and preferences. 3D printing and other additive manufacturing techniques will play a crucial role in this evolution, enabling intricate designs and rapid prototyping. This shift demands a re-evaluation of traditional manufacturing layouts and the adoption of flexible production systems.

Innovative Approaches Combining Craftsmanship and Automation

Integrating automation with traditional craftsmanship is not about replacing human touch but rather about augmenting it. Examples include robotic arms assisting in complex joinery tasks, while human artisans oversee and refine the final details. This approach ensures that the aesthetic and functional quality of the furniture remains high. Another innovation is the use of AI-powered design software, enabling more efficient and innovative designs based on user preferences and market trends.

Potential Impact on Job Markets and Skills Development

The automation of some tasks will inevitably impact job markets. However, this shift also creates new opportunities. The need for skilled technicians to maintain and operate automated machinery will rise, as will the demand for designers proficient in using 3D modeling and digital design tools. A crucial element of this transformation will be the development of programs that equip workers with the necessary skills to adapt to the changing demands of the industry.

Upskilling and reskilling initiatives will be essential for the workforce to remain competitive.

Role of Sustainability in Future Furniture Manufacturing

Sustainability will be a critical factor in the future of furniture manufacturing. Consumers are increasingly aware of the environmental impact of their purchases, leading to a growing demand for eco-friendly materials and production processes. This trend emphasizes the use of recycled and renewable resources, as well as the implementation of circular economy principles. Manufacturers must embrace sustainable practices to maintain their market position and meet the evolving expectations of environmentally conscious consumers.

Potential Future Trends in Furniture Manufacturing

| Trend | Impact | Challenges | Solutions |

|---|---|---|---|

| Personalized Furniture | Increased customer satisfaction, higher perceived value | High initial setup costs, potential for increased waste | Efficient design software, streamlined production processes, optimized material usage |

| On-Demand Manufacturing | Reduced lead times, enhanced customer experience | Balancing customization with production speed, material availability | Optimized supply chains, flexible manufacturing systems, robust inventory management |

| Automated Craftsmanship | Enhanced quality, increased productivity | Maintaining human oversight and expertise, cost of automation | Training programs for skilled technicians, collaboration between human artisans and robots |

| Sustainable Practices | Reduced environmental footprint, improved brand image | Finding sustainable alternatives to traditional materials, potential cost increase | Investment in research and development of sustainable materials, promotion of circular economy principles |

Case Studies of Successful Integration

Source: acctivate.com

Integrating craftsmanship and automation in furniture manufacturing presents a unique challenge, but successful examples demonstrate the potential for harmonious coexistence. Companies embracing this blend often find a path to enhanced quality, efficiency, and ultimately, market competitiveness. These models offer valuable insights into the strategies required for a successful integration process.

Examples of Successful Integration

Several furniture manufacturers have successfully navigated the integration of traditional craftsmanship with automated processes. This integration isn’t about replacing skilled artisans, but rather about augmenting their abilities and freeing them from repetitive tasks. This allows them to focus on the higher-level artistic and design aspects of the product.

| Company | Strategy | Results | Challenges |

|---|---|---|---|

| Herman Miller | Herman Miller employs a multi-faceted strategy. They leverage automation for tasks like cutting and assembly, allowing their skilled craftspeople to focus on the intricate joinery, finishing, and customization elements of their products. Their design approach often involves collaboration between designers, engineers, and craftspeople, emphasizing the interplay between human skill and technological advancement. | Significant improvements in production efficiency, while maintaining a high level of quality and customization. This strategy has helped them cater to a wider range of client needs, from individual consumers to large corporations. | The initial investment in automation and the need to retrain existing workforce were significant hurdles. Transitioning from traditional methods to a more automated workflow demanded careful planning and execution. |

| Knoll | Knoll integrates automation into their processes for repetitive tasks, such as cutting and shaping wood. This allows their skilled craftspeople to concentrate on tasks requiring greater precision and artistic judgment, including fine-tuning finishes and creating custom details. They also use automation for quality control, ensuring consistent results across different production runs. | Increased production output and consistent quality, resulting in greater customer satisfaction. This strategic shift has helped them maintain a strong brand identity associated with high-quality craftsmanship. | Maintaining the balance between maintaining a high level of craftsmanship and the efficiency gains from automation proved challenging. Ensuring that the automation did not compromise the quality of the final product was a key concern. |

| Ligne Roset | Ligne Roset utilizes robotic arms for precise cutting and assembly tasks, freeing their artisans to focus on the intricate details and personalized finishes. They prioritize collaboration between designers, craftspeople, and automation engineers to ensure that the automation enhances, rather than replaces, the human element in the process. | Improved production speed, enhanced quality control, and the ability to cater to a wider range of customization options for clients. This integration has led to an expansion of their product offerings and market reach. | The initial setup and integration of the robotic systems were complex and time-consuming. The need for specialized training for both the existing staff and the new automated systems required considerable resources. |

| Thonet | Thonet uses automation for tasks like material handling and initial assembly, but their artisans remain integral to the process. This approach ensures the high quality and detailed artistry of the final product, reflecting their commitment to the traditional craftsmanship. | Improved efficiency and productivity, without sacrificing the hallmark of Thonet’s craftsmanship. This allows the company to maintain their legacy while adapting to modern production demands. | The challenge was to ensure the automated systems did not detract from the meticulous, hand-crafted aspects of the process. It was crucial to maintain the aesthetic and quality standards for which the company is renowned. |

Maintaining Quality and Artistry

Successful integration strategies recognize that automation complements, rather than replaces, skilled craftsmanship. These companies prioritize the unique contributions of their artisans, empowering them to focus on the creative aspects of furniture design and production. Quality control measures are often integrated into the automated processes to maintain consistency and precision. A strong emphasis on design collaboration between designers, engineers, and craftspeople is crucial for the successful implementation of this strategy.

Impact on Design and Aesthetics

Automation in furniture manufacturing is fundamentally reshaping the landscape of design possibilities. By streamlining production processes and enabling greater precision, automation unlocks new avenues for creative expression in furniture aesthetics. This impact extends beyond mere efficiency, influencing the very nature of how furniture is conceived and realized.The integration of automation technologies allows for the exploration of intricate designs that were previously impractical or prohibitively expensive to produce through traditional methods.

This shift in production capabilities directly influences the aesthetic choices available to designers, pushing the boundaries of what’s possible in furniture form and function.

Automation’s Influence on Design Possibilities

Automation facilitates the creation of complex geometries and intricate patterns that would be challenging, if not impossible, to achieve with traditional craftsmanship. The precision and repeatability of automated systems enable the production of highly detailed designs previously limited by the skill and time constraints of human artisans. This opens doors for unique and innovative designs, moving beyond the limitations of traditional materials and construction techniques.

Impact on Aesthetic Choices

Automated manufacturing methods influence aesthetic choices by allowing for a wider range of material options and finishes. The precise control over processes allows for a more consistent application of finishes, resulting in a higher degree of aesthetic uniformity and quality. This uniformity can be balanced with bespoke features, creating a contrast between mass production and customized touches.

Leveraging Automation for Unique Designs

Designers can leverage automation’s capabilities to create unique and innovative furniture designs. By collaborating with automation specialists, designers can develop intricate, multi-layered pieces that were previously unattainable. Software tools and 3D modeling can be seamlessly integrated with automated machinery to translate design concepts into physical objects with remarkable precision.

Automation and Complex Designs

Automation is a powerful tool for producing furniture with complex or intricate designs. Automated cutting, joining, and finishing processes enable the creation of furniture pieces with intricate carvings, curved surfaces, and intricate patterns. This ability is transformative, moving away from the limitations of traditional methods in crafting such details.

Customized Furniture Through Automation

The integration of automation enables the production of customized furniture using automated systems. Software can allow for real-time design modifications, ensuring that the final product precisely matches the customer’s specifications. This ability allows for a personalized approach to furniture design, moving beyond one-size-fits-all designs.

Comparison of Traditional and Automated Furniture

| Design Style | Traditional Method | Automated Method | Outcomes |

|---|---|---|---|

| Minimalist | Straight lines, simple forms, often using wood. | Highly precise straight lines, geometric forms, potential for customized wood grain variations. | Enhanced precision in minimalist forms, potentially leading to a wider range of materials and finishes. |

| Ornate | Intricate carvings, detailed patterns, time-consuming to produce. | Precise replication of intricate carvings and patterns, leading to consistent aesthetic outcomes. | Allows for intricate designs, potentially faster production with high fidelity. |

| Curvilinear | Difficult to achieve smoothly curved shapes, potentially needing multiple joinery techniques. | Precise and smooth curved forms, possible with different materials (metal, plastic). | Wider range of curved forms, potentially leading to unique, aesthetically pleasing designs. |

| Modern | Clean lines, focus on functionality, limited by production methods. | Enhanced precision and customization in modern designs, potentially enabling bespoke pieces. | High precision and customization possibilities, leading to a wider range of designs within the modern aesthetic. |

Ethical Considerations and Social Impact

The integration of automation in furniture manufacturing presents a complex interplay of economic benefits and social responsibilities. While increased efficiency and productivity are alluring, potential negative impacts on workers and the environment demand careful consideration. Addressing these concerns proactively is crucial for a sustainable and equitable future for the industry.

Ethical Implications of Increasing Automation

Automation, while boosting production, can lead to job displacement in certain roles. This necessitates proactive measures to support affected workers through reskilling and upskilling initiatives, ensuring a smooth transition to new opportunities. Furthermore, the shift towards automation raises questions about the division of labor and the potential for widening the gap between highly skilled, automated roles and less-skilled positions.

This necessitates careful consideration of worker compensation and benefits in the context of automation’s impact on employment.

Potential Job Displacement and Workforce Adjustments

The introduction of automated systems may necessitate a significant adjustment in the workforce. Certain tasks currently performed by human workers may become automated, potentially leading to job losses in those areas. However, automation also creates new opportunities in areas like maintenance, programming, and oversight of automated systems. Strategies for retraining and upskilling are crucial to equip workers with the skills required for these emerging roles.

Reskilling and Upskilling Programs for Workers

Reskilling and upskilling initiatives are vital for workers facing potential job displacement. These programs should focus on equipping employees with the technical skills needed to operate and maintain automated systems, as well as develop competencies in related areas like design, product development, and quality control. Successful reskilling programs involve tailoring training to specific needs and providing support to facilitate career transitions.

Government support and industry partnerships can play a key role in implementing these initiatives effectively.

Maintaining a Balance Between Productivity and Social Responsibility

A delicate balance must be struck between boosting productivity through automation and ensuring social responsibility. Strategies that prioritize worker well-being and equitable compensation are paramount. Companies should proactively invest in reskilling programs, offer competitive wages, and provide comprehensive benefits packages to mitigate the potential negative impacts of automation. This proactive approach ensures a smooth transition and fosters a positive social impact.

Potential Impact on the Environmental Footprint of Furniture Manufacturing

Automation can potentially reduce the environmental footprint of furniture manufacturing. By optimizing processes and minimizing waste, automated systems can lead to significant reductions in energy consumption and material use. However, the environmental impact also depends on the materials used and the energy sources employed in the automated processes. Sustainable material sourcing and energy efficiency are crucial for a truly positive environmental outcome.

Ethical Considerations and Potential Social Impact of Automation in Furniture Production

| Concern | Impact | Mitigation Strategies | Long-Term Effects |

|---|---|---|---|

| Job Displacement | Loss of jobs in certain roles, potential for widening skill gap | Invest in reskilling/upskilling programs, offer support for career transitions, create new roles related to automation | Increased efficiency but potentially widened income disparity if not managed properly |

| Wage Inequality | Potential for widening gap between highly skilled automation roles and less skilled positions | Implement fair wage policies, ensure benefits for all employees, promote equity in compensation | Potential for social unrest if not addressed, risk of diminished consumer spending |

| Environmental Impact | Increased energy consumption if not using sustainable energy sources, potential waste | Use sustainable materials, implement energy-efficient technologies, optimize production processes | Reduced environmental impact if implemented sustainably, potential for increased consumer demand for eco-friendly products |

| Worker Safety | Potential risks associated with automated equipment, need for safety protocols | Implement robust safety measures, provide comprehensive training on safe equipment operation | Improved worker safety, increased productivity through safety conscious operations |

Final Wrap-Up

In conclusion, Craftsmanship Meets Automation: Balancing Art and Industry in Furniture Manufacturing highlights a transformative shift in the furniture industry. The integration of traditional craftsmanship with modern automation presents a dynamic path forward, offering opportunities for increased efficiency, improved quality, and a more sustainable future. By carefully considering the ethical implications and the potential impact on the workforce, the industry can embrace this evolution to create beautiful and functional furniture for generations to come.

Essential Questionnaire

What are the environmental impacts of automation in furniture manufacturing?

Automation can reduce waste and improve energy efficiency in the production process, potentially leading to a smaller environmental footprint. However, the manufacturing of automated equipment and the disposal of obsolete machinery can introduce environmental concerns. Responsible sourcing of materials and efficient waste management are crucial for a sustainable approach.

How does automation affect the design possibilities in furniture?

Automation opens doors to intricate and complex designs that might be challenging or impossible to create with traditional methods. It also enables the creation of customized furniture, adapting designs to individual preferences. However, the creative process is still influenced by human designers who guide the design parameters.

What skills will be needed in the future of furniture manufacturing?

The future furniture workforce will require a combination of traditional craftsmanship skills alongside proficiency in operating and maintaining automated systems. Technical skills, problem-solving abilities, and adaptability will be essential for success in this evolving industry.