Composite Materials Revolutionize Furniture Durability, offering a revolutionary approach to furniture design and construction. This innovative material, blending various components, promises superior durability and performance compared to traditional options. From enhanced resistance to environmental factors to groundbreaking design possibilities, composites are reshaping the future of furniture.

This overview explores the properties, manufacturing, and applications of composite materials in furniture. We’ll delve into their advantages in terms of durability, design flexibility, and sustainability, as well as address potential challenges and future directions.

Introduction to Composite Materials in Furniture

Source: sciencebridge.de

Composite materials are rapidly gaining traction in the furniture industry, offering a compelling blend of strength, durability, and aesthetic versatility. These materials, often engineered from multiple components, exhibit properties superior to traditional materials, leading to furniture pieces that are lighter, more resistant to damage, and potentially more sustainable. This shift towards composites is driven by both consumer demand for innovative designs and the inherent advantages of these materials.The application of composite materials in furniture design is not a recent phenomenon.

Early experiments with combining different materials, such as fibers and resins, have been ongoing for decades. However, recent advancements in manufacturing techniques and material science have significantly improved the performance and affordability of composite furniture, propelling this innovation into the mainstream. This evolution reflects a broader trend in design and engineering, where composite materials are increasingly preferred for their specific properties.

Overview of Composite Materials

Composite materials, in essence, are engineered materials made by combining two or more constituent materials with significantly different properties. This combination typically involves a reinforcement material (like fibers) embedded within a matrix material (like resin). The resulting material inherits the best characteristics of each component, creating a composite with unique properties.

Types of Composite Materials in Furniture

Various types of composite materials are employed in furniture construction, each with its own strengths and weaknesses. Common examples include:

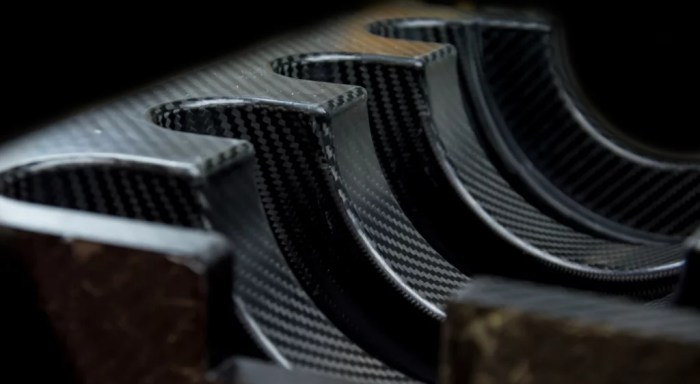

- Fiber-reinforced polymer (FRP) composites: These composites use fibers (such as carbon fiber, glass fiber, or aramid fiber) embedded in a polymer matrix (like epoxy or polyester resin). FRP composites are renowned for their high strength-to-weight ratio, making them suitable for creating lightweight, yet robust furniture pieces.

- Wood-polymer composites (WPC): These composites combine wood fibers or wood flour with a polymer matrix. WPCs offer a balance of wood’s aesthetic appeal and the durability of plastics, often used in outdoor furniture due to their resistance to moisture and rot.

- Metal-polymer composites: These composites integrate metal powders or fibers into a polymer matrix. This approach can yield furniture with improved strength, thermal stability, and corrosion resistance compared to traditional metal furniture.

Historical Context of Composite Use

The use of composite materials in furniture design has evolved alongside advancements in materials science and manufacturing techniques. Early applications often involved wood and other natural materials combined with resins for specific functionalities, like waterproofing or strengthening. The development of advanced polymers and fibers in the 20th century led to the creation of more sophisticated and durable composite materials.

Comparison with Traditional Materials

Traditional furniture materials like wood and metal each have their own strengths and weaknesses. Wood is often prized for its natural beauty and warmth, but it can be susceptible to damage, warping, and decay. Metal, on the other hand, is typically durable and strong, but it can be heavy and may not always complement aesthetic preferences. Composite materials bridge this gap, offering a balance of durability, aesthetics, and often, a lower environmental impact compared to some traditional methods.

Strengths and Weaknesses of Composite Materials

| Composite Material | Strengths | Weaknesses |

|---|---|---|

| Fiber-reinforced polymer (FRP) | High strength-to-weight ratio, corrosion resistance, customizable aesthetics | Can be brittle in some forms, may require specialized manufacturing |

| Wood-polymer composite (WPC) | Durable, moisture resistant, low maintenance, often aesthetically similar to wood | May not replicate the natural variations of wood, potential for warping under extreme conditions |

| Metal-polymer composite | High strength, thermal stability, corrosion resistance, potentially lighter than solid metal | May be more expensive than other options, potential for manufacturing complexities |

Enhanced Durability and Performance

Source: massivit3d.com

Composite materials are revolutionizing furniture design, offering a significant leap forward in durability and performance compared to traditional materials. Their inherent strength and resistance to environmental factors make them ideal for a wide range of applications, from outdoor seating to high-traffic indoor furniture.Composite furniture boasts exceptional longevity, largely due to the unique properties of the materials used in their construction.

This increased resilience directly translates into lower maintenance requirements and a longer lifespan for the finished product.

Superior Resistance to Wear and Tear

Composite furniture exhibits remarkable resistance to wear and tear, exceeding the performance of traditional materials like wood and metal. This superior resistance is a direct consequence of the composite’s inherent strength and the way its components are combined.

- Impact Resistance: Composite materials are inherently more resistant to impacts than traditional materials. For instance, a composite outdoor bench can withstand heavy use and occasional bumps from children or pets without showing significant damage, whereas a wooden bench might suffer dents or splinters under similar conditions.

- Scratch Resistance: Many composite materials have a higher scratch resistance than traditional options. This is particularly valuable for furniture exposed to high-traffic areas or homes with pets. For example, a composite coffee table is less susceptible to scratches from everyday use compared to a wooden one.

- Fading Resistance: Composite materials, especially those containing UV stabilizers, are less prone to fading or discoloration from prolonged sun exposure. This is crucial for outdoor furniture, which is often subjected to harsh sunlight.

Extended Lifespan Compared to Traditional Materials

The lifespan of composite furniture often surpasses that of its traditional counterparts. This is directly linked to the materials’ superior resistance to wear, tear, and environmental factors.

- Durability Comparison: A composite patio set can easily last 10-15 years or more under regular use, while a comparable wooden set might need replacement every 5-7 years due to weathering and wear. This translates to significant cost savings over the furniture’s lifespan.

- Long-Term Value: The extended lifespan of composite furniture translates to a higher long-term value proposition. The initial investment in composite furniture is often offset by the extended period of use, minimizing the need for frequent replacements.

Resistance to Environmental Factors

Composite materials excel in withstanding various environmental factors, enhancing their longevity and performance.

- Moisture Resistance: Unlike wood, which can warp, rot, or swell when exposed to moisture, composite materials are generally impervious to moisture damage. This makes them ideal for outdoor use or high-humidity environments.

- UV Resistance: Composite materials, particularly those with UV stabilizers, resist fading and degradation from ultraviolet (UV) light. This feature is critical for outdoor furniture exposed to direct sunlight.

- Temperature Fluctuation Resistance: Composite materials maintain their structural integrity and performance across a wider range of temperatures compared to some traditional materials. This stability is crucial for furniture subjected to significant temperature variations, like outdoor furniture.

Manufacturing Process and Longevity

The manufacturing process of composite furniture components significantly impacts the furniture’s longevity. Modern composite materials are often engineered with advanced manufacturing techniques, ensuring uniform strength and resilience.

- Advanced Manufacturing: Modern composite materials often utilize advanced molding or layering techniques to create stronger and more durable components. These techniques ensure that the composite material is uniformly distributed, resulting in consistent performance.

- Material Selection: The careful selection of composite materials, including fillers, resins, and reinforcing fibers, directly impacts the final product’s durability. High-quality components lead to superior performance over time.

Comparative Damage Resistance

| Material | Scratch Resistance | Impact Resistance | Moisture Resistance | UV Resistance |

|---|---|---|---|---|

| Wood | Low | Moderate | High (depending on treatment) | Low |

| Metal | Moderate | High | High | High |

| Composite (e.g., WPC) | High | High | High | High |

Design and Aesthetics

Composite materials offer a revolutionary approach to furniture design, transcending traditional limitations. Their inherent versatility allows for innovative forms and aesthetics previously unimaginable with conventional materials. This flexibility extends beyond structural enhancements, encompassing a wide spectrum of design possibilities.Composite materials, with their adaptable nature, empower designers to push creative boundaries, creating furniture pieces that are both functional and visually captivating.

The aesthetic options available are significantly broader than with traditional materials, opening doors to new styles and expressions.

Design Possibilities

Composite materials offer a wide array of design possibilities in furniture creation. Their inherent strength and light weight allow for intricate designs and unique shapes that would be impractical or impossible with traditional materials. This leads to a dramatic increase in the design space available to furniture makers. For example, curved or organic forms, previously limited by material properties, are now easily achievable.

Innovative Furniture Designs

Several innovative furniture designs incorporate composite materials. One example is a modular sofa system where the individual components are crafted from a lightweight, yet durable composite, enabling effortless reconfiguration. Another example is a coffee table with a complex, sculpted top made from a composite material, showcasing its potential for intricate detailing. These examples highlight the material’s adaptability and design flexibility.

Aesthetic Versatility

Composite materials demonstrate remarkable aesthetic versatility. Their smooth surfaces allow for sleek, modern designs, while their structural properties enable the creation of complex shapes and patterns. The inherent flexibility of composite materials allows designers to create visually appealing pieces, ranging from minimalist designs to elaborate, artistic creations.

Material Colors and Finishes

| Composite Material | Color Options | Finishes |

|---|---|---|

| Carbon Fiber Reinforced Polymer (CFRP) | Black, Dark Grey, Light Grey, Red, Green | Matte, Glossy, Textured |

| Fiberglass Reinforced Polymer (FRP) | Various colors including custom hues, White, Beige, Teal | Smooth, Sandblasted, Wood-grain effect |

| Polymer Concrete | Many colors; concrete colors, Gray, Beige, Brown, and customized colors | Painted, stained, polished |

This table provides a glimpse into the vast array of colors and finishes achievable with composite materials. Custom colors and finishes are increasingly common, catering to specific design preferences and creating unique visual identities for furniture.

Unique Textures and Patterns

Composite materials offer the potential for a wide range of unique textures and patterns. The layering, molding, and shaping techniques applicable to these materials allow for the creation of embossed designs, intricate patterns, and even the simulation of natural materials like wood grain or stone. These possibilities expand the aesthetic options for furniture, moving beyond simple colors and finishes.

Aesthetic Appeal Comparison

Composite furniture often boasts a modern and sleek aesthetic, contrasting with the more traditional styles of wood or metal furniture. However, the visual appeal of composite furniture is not solely dependent on its modern aesthetic. Composite materials, with their diverse color and finish options, can be styled in a variety of ways to complement different design aesthetics. Composite furniture is frequently associated with a high-tech, futuristic look.

However, the versatility of composite materials allows for the creation of pieces that are both modern and classic, depending on the chosen design and aesthetic.

Manufacturing and Sustainability

Composite furniture manufacturing offers a compelling blend of design flexibility and potential for environmentally responsible production. The process, while often involving specialized techniques, can be optimized for sustainability, minimizing waste and maximizing resource efficiency. Understanding the interplay between manufacturing methods, material sourcing, and end-of-life scenarios is crucial to realizing the full potential of composite furniture.

Manufacturing Processes

The creation of composite furniture typically involves layering or molding various components. Resin-infused fibers, such as fiberglass or carbon fiber, are commonly used. These materials can be molded into intricate shapes or layered to form robust panels, subsequently assembled into furniture pieces. Different manufacturing techniques are employed depending on the desired final product and the complexity of the design.

For instance, injection molding is suitable for simpler shapes, while more complex designs may benefit from vacuum infusion or pultrusion.

Environmental Impact of Composite Materials

The environmental footprint of composite furniture is significantly impacted by the raw materials used and the manufacturing process itself. Factors like energy consumption during production, the lifecycle of the raw materials, and the potential for waste generation must be carefully considered. While composites often offer reduced material use compared to traditional wood, the environmental impact varies widely based on the specifics of material selection and manufacturing.

Recyclability and Reusability

The recyclability of composite furniture components depends heavily on the specific composite material composition. Some composites, particularly those with recyclable resins, are more easily recycled compared to others. The reusability of composite components is also a key factor. Components like frames or structural elements can often be salvaged and reused, reducing waste and promoting circularity. Currently, the development of effective recycling infrastructure is critical for achieving full recyclability.

Raw Material Sources

The sources of raw materials for composite furniture production are diverse. Resins, such as polyester or epoxy, are often derived from petroleum products. Reinforcing fibers, like carbon fiber and fiberglass, can be manufactured from various sources, potentially including recycled materials. The sustainability of composite furniture hinges in part on the sourcing and processing of these materials. The availability of sustainably sourced materials, such as bio-based resins, significantly influences the overall environmental impact.

Potential for Sustainable Composite Furniture Production

The potential for sustainable composite furniture production is significant. Innovative approaches like using recycled materials, optimizing manufacturing processes, and developing bio-based resins can drastically reduce the environmental impact of these products. Furthermore, the design of furniture with modular components and easily replaceable parts fosters reusability and extended lifespans. Companies that integrate sustainability into every stage of the production process can position themselves for market success.

Environmental Impact Scores

| Material | Energy Consumption (kWh/kg) | Waste Generation (kg/kg) | Carbon Footprint (kg CO2e/kg) |

|---|---|---|---|

| Solid Wood | 10 | 0.5 | 1.5 |

| Fiberglass Composite | 5 | 0.2 | 0.8 |

| Carbon Fiber Composite | 15 | 0.1 | 1.2 |

Note: These are illustrative values and can vary significantly based on specific manufacturing processes and material sourcing.

Applications and Case Studies: Composite Materials Revolutionize Furniture Durability

Composite materials are rapidly transforming the furniture industry, offering enhanced durability, performance, and design flexibility. This section explores the diverse applications of these materials in various furniture types, showcasing real-world examples and highlighting their advantages. Case studies illustrate the practical use of composite materials in different environments, from residential settings to demanding commercial spaces.Composite furniture is finding widespread use across a range of applications.

The unique properties of these materials, such as their resistance to weathering, impact, and decay, make them particularly suitable for outdoor environments. Furthermore, the aesthetic versatility of composites allows for the creation of visually appealing furniture pieces that seamlessly blend with different design styles.

Specific Furniture Items Incorporating Composites

Composite materials are now integral components in a wide range of furniture items. Common examples include outdoor patio sets, garden benches, and decking materials. Furthermore, high-performance composite materials are being used in commercial furniture like durable reception desks and robust waiting area seating. These materials’ inherent resistance to environmental factors makes them a compelling choice for various outdoor furniture applications.

Types of Furniture Excelling with Composite Materials, Composite Materials Revolutionize Furniture Durability

Composite materials excel in several types of furniture due to their robust nature. Outdoor furniture, particularly patio sets, lounge chairs, and garden tables, often benefit from the weather resistance and longevity offered by composites. Similarly, composite materials are finding increasing use in commercial settings, providing durable and aesthetically pleasing solutions for reception areas, waiting rooms, and even outdoor café furniture.

Their resilience and resistance to fading make them ideal for high-traffic areas.

Case Studies of Composite Furniture in Various Environments

Several case studies demonstrate the practical application of composite furniture in diverse environments. One notable example involves a restaurant chain using composite outdoor seating to create a vibrant and inviting atmosphere for customers. The durable composite materials withstand the elements and frequent use, reducing maintenance costs and ensuring a long-lasting investment. Furthermore, numerous residential projects have incorporated composite materials for decking and outdoor seating, achieving both aesthetic appeal and practical durability.

Comparison Table of Composite Furniture Applications

| Furniture Type | Material Type | Environment | Advantages |

|---|---|---|---|

| Outdoor Patio Sets | Composite (e.g., wood-polymer composites) | Gardens, patios, balconies | Weather resistance, low maintenance, long lifespan |

| Indoor Dining Chairs | Composite (e.g., carbon fiber composites) | Restaurants, homes | Lightweight, high strength, varied aesthetic options |

| Commercial Reception Desks | Composite (e.g., high-density polyethylene composites) | Offices, businesses | Durability, stain resistance, easy cleaning |

Advantages of Composite Materials in Outdoor Furniture

Composite materials offer several compelling advantages for outdoor furniture compared to traditional materials like wood or metal. Their primary benefit is the remarkable resistance to weather elements, including moisture, UV radiation, and extreme temperatures. This translates to a significantly longer lifespan and reduced maintenance needs, saving users time and money in the long run. Moreover, composite materials are typically less prone to rot, decay, or insect infestation, further enhancing their durability in outdoor environments.

Potential for Composite Materials in Future Furniture Trends

Composite materials are poised to play a significant role in shaping future furniture trends. Their versatility allows for innovative designs and the creation of sustainable products. Expect to see a greater emphasis on modular and adaptable furniture pieces made from composite materials, offering flexibility and customization options for consumers. Furthermore, advancements in composite material technology will likely lead to even more durable and aesthetically pleasing furniture designs, pushing the boundaries of what’s possible in the industry.

Challenges and Future Directions

Composite materials, while offering significant advantages in furniture design, face certain hurdles that need addressing. Overcoming these challenges is crucial for widespread adoption and the realization of their full potential in the furniture industry. Further research and development are vital for refining manufacturing processes, optimizing material properties, and expanding the range of applications.Current research and development efforts are focused on improving the performance characteristics of composite materials, such as enhancing their strength, durability, and aesthetic appeal.

New manufacturing techniques are being explored to achieve cost-effectiveness and reduce environmental impact. This progress promises exciting developments in the coming years.

Potential Limitations

Several limitations currently hinder the widespread adoption of composite materials in furniture. Material costs can be higher compared to traditional materials, although this is often offset by the durability and reduced maintenance requirements. The lack of standardized testing procedures for composite furniture can make comparative assessments difficult. Additionally, the intricate design processes required for complex composite structures sometimes pose challenges.

Manufacturing processes can also be complex, requiring specialized equipment and skilled labor.

Research and Development Efforts

Extensive research is underway to address these limitations. Researchers are exploring innovative manufacturing techniques, such as 3D printing and fiber placement, to produce complex shapes and designs with high precision. Significant efforts are focused on developing cost-effective composite materials with enhanced properties. This includes incorporating recycled or sustainable materials to create environmentally friendly solutions. Moreover, research is progressing in the development of more sophisticated testing protocols to ensure the reliability and safety of composite furniture.

Future Directions

The future of composite materials in furniture is promising. Anticipate greater integration of advanced materials, such as carbon fiber and high-performance polymers, leading to lighter, stronger, and more durable furniture. The evolution of 3D printing techniques will enable intricate designs and customized furniture. Furthermore, the trend towards sustainable materials and manufacturing processes will continue to shape the development of composite furniture.

Examples like the use of recycled plastics in composite materials for outdoor furniture demonstrate the growing emphasis on eco-friendly options.

Current Challenges and Potential Solutions

| Challenge | Potential Solution |

|---|---|

| High material costs | Development of cost-effective composite formulations, optimization of manufacturing processes, and exploration of recycled/sustainable materials. |

| Lack of standardized testing procedures | Establishment of industry-wide standards for testing the performance of composite furniture, ensuring consistent quality control. |

| Complexity in design and manufacturing | Advancement in design software and automation in manufacturing processes, along with training and education of skilled labor. |

| Limited aesthetic choices | Research and development of new surface treatments and finishing techniques for improved aesthetics. |

| Potential for material degradation in specific environments | Development of materials resistant to weathering, UV exposure, and other environmental factors, tailoring materials for specific applications. |

Impact of Technological Advancements

Technological advancements will revolutionize the composite furniture industry. Advanced materials science will enable the creation of furniture with unparalleled strength and lightweight properties. 3D printing will enable intricate and customized designs. Smart materials, responsive to environmental changes, will add new functionalities.

Addressing Specific Furniture Needs

Composite materials offer significant potential for addressing specific furniture needs. Their strength and durability make them suitable for heavy-duty applications, such as outdoor furniture or commercial seating. Their customizable nature allows for the creation of furniture with specific aesthetic requirements, from minimalist designs to elaborate artistic expressions. For instance, carbon fiber composites could create extremely lightweight yet robust furniture, perfect for outdoor recreation or sports venues.

Last Recap

In conclusion, composite materials are poised to transform the furniture industry, offering a compelling combination of durability, design freedom, and sustainability. While challenges remain, the potential for innovation and environmental responsibility is significant. The future of furniture may well be composite.

FAQ Guide

What are the most common types of composite materials used in furniture?

Common composite materials include reinforced polymers, wood-polymer composites, and fiber-reinforced plastics. Their specific properties and characteristics depend on the materials combined.

How do composite materials compare to traditional materials like wood and metal in terms of cost?

The cost of composite materials can vary depending on the specific components and manufacturing process. While some composites might be more expensive than traditional wood, they often offer a longer lifespan and lower maintenance costs, potentially offsetting the initial price difference over time.

What are the environmental impacts of using composite materials in furniture production?

The environmental impact of composite materials depends heavily on the specific materials used and the manufacturing processes involved. Some composite materials offer the potential for reduced resource consumption and lower waste compared to traditional materials, though careful consideration of the entire life cycle is essential.

Are there any specific safety concerns related to composite furniture?

Generally, composite furniture is considered safe for use. However, specific safety guidelines might vary depending on the material and manufacturing process. Always check product information for specific safety details.