Smart Technology in Furniture Manufacturing is reshaping the furniture industry, integrating technology into every stage of production from design to delivery. This innovative approach is transforming how furniture is conceived, built, and experienced, leading to a more efficient and sustainable manufacturing process while also offering enhanced user experience. The evolution of manufacturing techniques, from traditional methods to those incorporating advanced technologies like AI and robotics, is driving this change.

The integration of smart technology is evident in the use of sensors, actuators, and data analytics, enabling greater customization and personalization in furniture design. This allows for furniture to be more responsive to individual user needs, optimizing comfort and functionality. From adjustable lighting to embedded charging pads, the potential for personalized and intelligent furniture is vast.

Introduction to Smart Furniture Manufacturing

Traditional furniture manufacturing relied heavily on manual labor and repetitive processes. However, the industry has undergone a significant transformation, driven by technological advancements, creating a new era of smart furniture manufacturing. This evolution reflects a wider trend across various sectors, emphasizing efficiency, customization, and enhanced customer experience.Smart furniture manufacturing leverages technology to streamline production, personalize designs, and gather valuable data for continuous improvement.

Core to this concept are the principles of connectivity, automation, and data analysis. These technologies work together to create furniture that is not only aesthetically pleasing but also functional, sustainable, and tailored to individual needs.

Evolution of Furniture Manufacturing

Furniture manufacturing has evolved from rudimentary techniques to sophisticated processes incorporating advanced technologies. Early methods relied on handcrafted techniques, resulting in limited production volumes and high costs. The introduction of machinery and assembly lines marked a significant step towards mass production, increasing efficiency and reducing production time. More recently, digital design tools and automated production processes have further refined the manufacturing process.

This ongoing evolution is now reaching a new apex with the emergence of smart furniture manufacturing.

Core Concepts of Smart Furniture Technology

Smart furniture technology is characterized by three interconnected elements: connectivity, automation, and data analysis. Connectivity allows for seamless communication between different parts of the production process, enabling real-time data exchange and remote monitoring. Automation streamlines tasks, reducing human error and increasing output. Data analysis allows manufacturers to collect, interpret, and use information to enhance efficiency, optimize designs, and understand customer preferences.

These technologies work in synergy to create a dynamic and responsive manufacturing environment.

Potential Benefits of Smart Technology

Implementing smart technology in furniture manufacturing offers a plethora of advantages. Increased efficiency and productivity are key benefits, achieved through streamlined processes and automated tasks. Reduced production costs are another significant advantage, stemming from optimized resource utilization and reduced waste. Furthermore, improved product quality and consistency are achieved through the integration of advanced monitoring and control systems.

Enhanced customization options allow manufacturers to cater to specific customer needs, potentially leading to increased sales and market share.

Types of Smart Technologies in Furniture Manufacturing

A range of technologies contribute to the smart furniture manufacturing process. Sensors are crucial for monitoring various aspects of production, including material usage, machine performance, and product quality. Actuators enable automated adjustments and movements in the manufacturing process, ensuring precise execution of tasks. Artificial intelligence (AI) is employed for tasks such as predictive maintenance, quality control, and design optimization.

These technologies, when integrated, create a sophisticated and intelligent manufacturing system.

- Sensors: Sensors are used to monitor critical parameters like temperature, pressure, and material properties during the manufacturing process. This allows for real-time adjustments and prevents errors, maintaining consistent quality. Examples include sensors measuring wood moisture content or the pressure applied during pressing processes. This continuous monitoring ensures adherence to standards and minimizes waste.

- Actuators: Actuators automate movements and adjustments in the manufacturing process, ensuring precision and efficiency. For instance, robotic arms can precisely position components, while automated clamping systems ensure uniform pressure. These actuators contribute to speed and accuracy in tasks like gluing and assembly.

- Artificial Intelligence (AI): AI algorithms can analyze vast amounts of data collected from sensors and machines. This data analysis helps in predicting maintenance needs, optimizing production schedules, and improving product design. For example, AI can predict when a machine needs maintenance, preventing costly downtime. AI also aids in analyzing customer preferences and trends to inform design decisions, leading to products that meet specific needs.

Design and Development of Smart Furniture

Integrating smart technology into furniture design presents a fascinating opportunity to enhance user experience and functionality. This involves a careful consideration of user needs, technological capabilities, and aesthetic design principles. The transition from traditional furniture design to incorporating smart features necessitates a paradigm shift in the design process, demanding a new understanding of the interaction between humans and technology.Traditional furniture design methodologies typically prioritize aesthetics, durability, and ergonomics.

These methods often focus on the physical attributes of the furniture piece, while smart furniture design incorporates a layer of digital intelligence. This necessitates a holistic approach, considering the user’s interaction with the piece, its environmental impact, and its integration with other smart home systems.

Integrating Smart Technology into Furniture Design

A streamlined process for integrating smart technology into furniture design should begin with a thorough understanding of the target user and their needs. This involves conducting user research to identify specific pain points and opportunities for improvement. Following this, designers should explore potential smart features that could address these needs and improve the user experience. This should include prototyping and testing different functionalities and interactions to ensure the features are intuitive and effective.

Ultimately, the design should incorporate the smart features seamlessly into the aesthetic and functionality of the furniture piece.

Comparison of Traditional and Smart Furniture Design Methodologies

Traditional furniture design relies heavily on manual processes, skilled craftsmanship, and aesthetic judgment. Smart furniture design, conversely, incorporates digital design tools and 3D modeling, allowing for greater precision and customization. Moreover, smart furniture designs often incorporate iterative prototyping and user feedback loops to refine the final product. This results in a design process that is more responsive to user needs and technological advancements.

However, traditional methods maintain a crucial role in the manufacturing process, contributing to the physical construction and craftsmanship of the smart furniture.

Challenges in Designing Smart Furniture

Several challenges arise when designing smart furniture. A key consideration is the integration of sensors and actuators into the furniture structure without compromising its aesthetics or functionality. The cost-effectiveness of incorporating these technologies is another significant hurdle. Smart features often require specialized components and manufacturing processes, potentially raising production costs. Careful planning and cost analysis are essential to ensure the finished product remains competitive.

Design Considerations for Sensors and Actuators

Careful consideration is needed when incorporating sensors and actuators into furniture. Placement of sensors must be strategically chosen to maximize their effectiveness without compromising the furniture’s form or function. The choice of sensors and actuators should be driven by the desired functionality. For instance, pressure sensors might be used in seating to adjust comfort levels, while proximity sensors might be used for automated lighting.

The integration of these components should be visually seamless and not detract from the overall design.

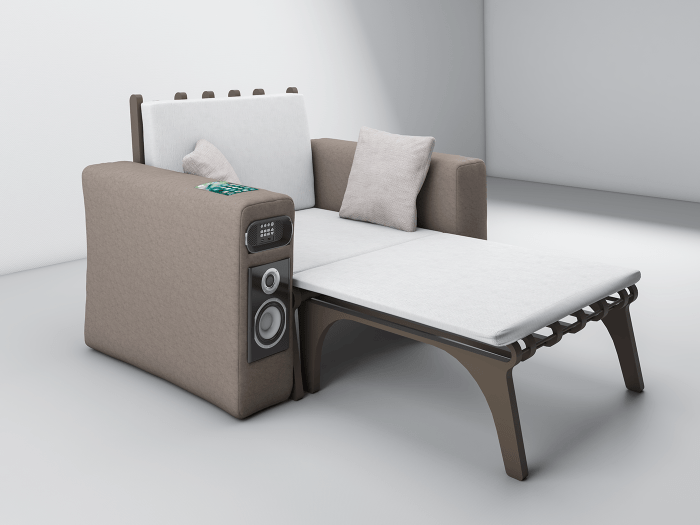

Smart Furniture Designs by Functionality

| Functionality | Description | Example |

|---|---|---|

| Adjustable Lighting | Furniture pieces with integrated lighting that can be adjusted based on user preference or ambient conditions. | A coffee table with LED lighting that changes color or intensity. |

| Embedded Charging Pads | Furniture that includes built-in charging solutions for wireless devices. | A side table with an embedded wireless charging pad for smartphones. |

| Interactive Surfaces | Furniture with touch-sensitive surfaces that enable users to control various functions or access information. | A dining table with a touch-sensitive surface that can control lighting, music, or access online resources. |

| Adaptive Seating | Furniture that adjusts its form and function based on user preferences or needs. | A chair that dynamically adjusts its backrest and leg support to provide personalized comfort. |

Manufacturing Processes and Automation

Source: graana.com

Smart furniture manufacturing is undergoing a significant transformation, driven by the integration of advanced technologies. This shift is impacting every stage of the process, from material selection to final assembly, leading to increased efficiency and customization capabilities. The introduction of automation, in particular, promises to streamline operations and improve overall productivity.

Various Manufacturing Processes

Several manufacturing processes are employed in the production of smart furniture. These processes range from traditional methods to cutting-edge technologies, each contributing to the overall design and functionality of the final product. 3D printing, CNC machining, and robotic assembly are becoming increasingly prevalent, allowing for complex designs and intricate parts.

- 3D printing enables the creation of intricate shapes and customized components with minimal material waste. This technology is particularly useful for prototyping and producing unique, one-of-a-kind pieces.

- CNC machining is employed for precise cutting and shaping of materials, such as wood or metal. This method ensures consistent dimensions and intricate designs, ideal for mass production.

- Robotic assembly is crucial for repetitive tasks in furniture manufacturing. Robots are capable of performing these tasks with high accuracy and speed, minimizing human error and increasing output.

Advantages of Automation in Smart Furniture Manufacturing

Automation, facilitated by smart technologies, offers numerous advantages in furniture manufacturing. These benefits include improved efficiency, reduced production time, and enhanced product quality. Furthermore, automation allows for greater flexibility in responding to changing customer demands.

- Increased efficiency: Automation streamlines processes, reducing manual intervention and increasing production speed. This leads to lower operational costs and faster turnaround times.

- Reduced production time: Automated systems can work continuously, minimizing delays and accelerating the manufacturing cycle. This is especially beneficial for high-volume production.

- Enhanced product quality: Robots perform tasks with precision and consistency, minimizing human error and producing higher-quality products. This results in fewer defects and increased customer satisfaction.

- Greater flexibility: Smart systems allow for quick adaptation to changing customer preferences and production requirements. This agility is crucial in a market that demands customization and rapid response.

Impact of Smart Technology on Material Selection

Smart technologies are revolutionizing material selection in furniture manufacturing. This evolution is driven by the ability to analyze material properties and performance characteristics more effectively. The integration of sensors and data analytics leads to more informed decisions, resulting in optimized material choices.

- Material properties analysis: Sensors and data analytics can precisely measure material properties like strength, durability, and sustainability. This data-driven approach facilitates better material selection for specific applications.

- Performance optimization: Testing and analyzing material performance under various conditions (e.g., stress, temperature) allows manufacturers to select materials that meet specific design requirements and ensure optimal performance.

- Sustainability considerations: Smart technologies can analyze the environmental impact of different materials, leading to more sustainable choices. This factor is increasingly important to consumers and businesses alike.

Role of Robotics in Automating Tasks

Robotics play a vital role in automating various tasks within furniture manufacturing. Their precision and speed enable the automation of complex operations, leading to increased output and reduced labor costs. Robotic arms and systems can be programmed to handle a wide array of tasks.

- Automated cutting: Robotic arms equipped with precise cutting tools can efficiently cut materials according to design specifications.

- Automated assembly: Robots can assemble furniture components with high speed and accuracy, minimizing human error and ensuring consistent quality.

- Automated finishing: Robotic systems can apply finishes to furniture with uniform consistency and precision, leading to a higher standard of quality.

Enhancement of Manufacturing Efficiency

The following table demonstrates how smart technologies can enhance the efficiency of each step in the manufacturing process.

| Manufacturing Step | Traditional Method | Smart Technology Approach |

|---|---|---|

| Material Cutting | Manual cutting with saws; potential for error | CNC machining; high precision, reduced waste |

| Component Assembly | Manual assembly; time-consuming, prone to errors | Robotic assembly; high speed, high accuracy |

| Finishing | Manual application of finishes; inconsistencies in quality | Robotic finishing; uniform application, high quality |

| Quality Control | Visual inspection; time-consuming, subjective | Automated sensors; real-time data analysis, consistent results |

Materials and Technologies

The selection of materials plays a crucial role in the design and functionality of smart furniture. Advanced materials, combined with smart technologies, enable the creation of furniture that responds to user needs and preferences, while also offering improved sustainability in manufacturing. This section explores the application of advanced materials, the enhancement of sustainability, and the role of sensors in monitoring the manufacturing process.The integration of smart technologies with traditional furniture manufacturing techniques allows for the development of furniture that is not only aesthetically pleasing but also highly functional and sustainable.

This includes using advanced materials like composites and polymers, as well as incorporating smart fabrics and sensors.

Advanced Materials in Smart Furniture

Advanced materials are essential for the development of smart furniture, allowing for the integration of functionalities that were previously impossible. Composites, polymers, and smart fabrics are among the most promising materials in this area. Composites offer exceptional strength-to-weight ratios, while polymers allow for the creation of complex shapes and customizable functionalities. Smart fabrics, meanwhile, introduce interactive elements and adaptable responses to user input.

Sustainability in Smart Furniture Manufacturing

Smart technologies are increasingly used to improve the sustainability of furniture manufacturing. Reduced material waste, optimized energy consumption, and minimized environmental impact are key goals. Sustainable materials, combined with efficient manufacturing processes, contribute to a more environmentally friendly furniture industry.

Examples of Sustainable Materials

Several sustainable materials are being incorporated into smart furniture designs. Recycled plastics, bamboo, and bio-based polymers are gaining popularity due to their reduced environmental footprint. These materials can be combined with advanced composites and smart fabrics to create furniture that is both functional and environmentally responsible. For example, a chair made from recycled plastic frames and a bio-based polymer seat would combine sustainability with modern design.

Role of Sensors in Monitoring Manufacturing

Sensors are crucial for monitoring and controlling the manufacturing process, ensuring quality and efficiency. Real-time data from sensors allows for the identification of issues and adjustments to processes. This proactive approach minimizes waste and improves overall manufacturing efficiency. For instance, sensors can monitor material properties during the manufacturing process, ensuring the quality of the final product.

Comparison of Materials for Smart Furniture

| Material | Suitability for Smart Furniture | Advantages | Disadvantages |

|---|---|---|---|

| Recycled Plastics | Excellent for frames, affordable | Cost-effective, reduces reliance on virgin materials, readily available | May have lower strength compared to virgin plastics, potential for variations in quality depending on the source |

| Bamboo | Good for frames, eco-friendly | Renewable resource, strong and durable, aesthetic appeal | Can be susceptible to moisture damage, may require specific treatments for longevity |

| Bio-based Polymers | Suitable for seats, customizable | Reduced carbon footprint, customizable properties, can mimic traditional materials | Potential for higher cost compared to traditional plastics, ongoing research and development needed |

| Advanced Composites | Suitable for complex shapes, high strength | Exceptional strength-to-weight ratio, allows for complex designs, customizable | Higher production costs, may require specialized manufacturing techniques |

Data Collection and Analysis in Smart Furniture

Source: behance.net

Smart furniture, with its integration of technology, generates a wealth of data. This data, when effectively collected and analyzed, can significantly enhance the design, manufacturing, and user experience of these products. Understanding how this data is collected and used is crucial for optimizing the entire lifecycle of smart furniture.Data analysis plays a vital role in identifying trends and patterns within the vast amounts of information generated by smart furniture.

By utilizing sophisticated algorithms and techniques, manufacturers can uncover insights that lead to improved product performance, user satisfaction, and long-term sustainability.

Data Collection Methods

Smart furniture incorporates a variety of sensors and embedded systems to collect crucial data. These sensors provide insights into various aspects of the furniture, from user interactions to environmental conditions. Accelerometers and gyroscopes can monitor movement and stress on the furniture, while temperature and humidity sensors can track environmental conditions. Further, proximity sensors can track the presence and movements of users.

Embedded systems process this raw data, preparing it for analysis and interpretation.

Significance of Data Analysis

Data analysis in smart furniture manufacturing is critical for optimizing the entire process. Analyzing user interactions allows for the identification of areas where the furniture design can be improved. Data from production processes helps to optimize manufacturing workflows, minimizing waste and maximizing efficiency. Analyzing data related to user interactions and product usage can also enhance the user experience.

Predictive Maintenance

Data analysis is instrumental in predicting potential maintenance needs. Patterns in sensor data can identify potential failures or malfunctions before they occur. For instance, consistent fluctuations in vibration data might indicate a component that is likely to fail. Predictive maintenance can significantly reduce downtime and improve the overall lifecycle of smart furniture, resulting in a lower cost of ownership for the user.

A real-life example is the use of vibration sensors in automated production equipment, which predict and prevent failures. Such data-driven predictive maintenance is vital in reducing unplanned downtime and maintenance costs.

Privacy and Security Considerations

The collection and use of data from smart furniture raise important privacy and security concerns. Protecting user data is paramount. Robust security measures are essential to prevent unauthorized access and data breaches. Data encryption and access controls are vital to ensure that sensitive information remains confidential. Furthermore, transparent data policies and user consent procedures are crucial to maintaining trust and compliance.

Flowchart of Data Collection, Analysis, and Feedback, Smart Technology in Furniture Manufacturing

The flowchart above illustrates the process of data collection, analysis, and feedback in smart furniture manufacturing. Raw data is collected from various sensors and embedded systems within the furniture. This data is then processed and analyzed to identify patterns and trends. The analysis results provide insights for improving the design, manufacturing, and user experience. Feedback loops allow for iterative improvements in the product, leading to a continuous cycle of development and enhancement.

The process is cyclical, enabling continuous improvement and enhancement of the smart furniture.

Supply Chain Management and Logistics: Smart Technology In Furniture Manufacturing

Source: shelby-news.com

Smart technologies are revolutionizing furniture manufacturing, and this transformation significantly impacts supply chain management and logistics. From sourcing raw materials to delivering finished products, every stage benefits from streamlined processes and enhanced visibility. Real-time data and advanced analytics provide crucial insights, enabling proactive decision-making and optimizing resource allocation.The integration of smart technologies fosters a more agile and responsive supply chain, crucial for navigating the complexities of the modern market.

This agility allows furniture manufacturers to adapt quickly to fluctuating demands, evolving consumer preferences, and unexpected disruptions.

Impact of Smart Technologies on Supply Chain Management

Smart technologies, including IoT sensors, data analytics, and AI, are profoundly impacting supply chain management in furniture manufacturing. Real-time tracking of inventory, raw materials, and finished goods provides unparalleled visibility, enabling manufacturers to monitor movements, predict potential delays, and address issues proactively. This proactive approach reduces lead times, minimizes storage costs, and optimizes resource utilization throughout the entire supply chain.

Real-Time Tracking and Monitoring for Optimized Logistics

Real-time tracking and monitoring, enabled by IoT sensors and GPS technology, significantly optimize logistics. Tracking systems provide real-time visibility into the location and status of shipments, enabling manufacturers to monitor delivery progress, anticipate potential delays, and adjust schedules accordingly. This transparency fosters greater collaboration between different partners in the supply chain, leading to improved coordination and reduced risks. For instance, a furniture manufacturer can monitor the transportation of lumber from the forest to the factory, tracking conditions like temperature and humidity to ensure the quality of the raw material.

This real-time data allows for adjustments to the delivery route, if necessary, to ensure the lumber arrives in optimal condition.

AI and Machine Learning in Inventory Management

AI and machine learning algorithms can significantly optimize inventory management. By analyzing historical sales data, market trends, and external factors, these algorithms can predict future demand with greater accuracy. This predictive capability allows manufacturers to adjust inventory levels dynamically, minimizing storage costs, reducing stockouts, and preventing overstocking. For example, an AI system can predict increased demand for a specific style of chair based on social media trends and online sales data, allowing the manufacturer to proactively increase production and prevent a shortage.

Challenges of Integrating Smart Technologies into Existing Supply Chains

Integrating smart technologies into existing supply chains presents certain challenges. These include the high initial investment required for implementing new technologies, the need for significant changes in existing processes, and the challenge of integrating data from various disparate sources. Furthermore, there’s the need to ensure data security and privacy throughout the entire supply chain.

Improving Each Stage of the Supply Chain with Smart Technology

| Stage of Supply Chain | How Smart Technology Improves |

|---|---|

| Sourcing Raw Materials | Smart contracts and automated bidding systems can optimize sourcing and ensure compliance with sustainability standards. Real-time tracking of raw material quality and origin enhances traceability and reduces risks. |

| Production | Automated machinery, predictive maintenance, and real-time monitoring improve efficiency and reduce downtime. Data analytics can identify bottlenecks and areas for process improvement. |

| Inventory Management | AI-powered systems can predict demand, optimize inventory levels, and minimize storage costs. Real-time tracking ensures accurate inventory levels. |

| Logistics and Delivery | Real-time tracking, route optimization, and predictive delivery modeling improve efficiency, reduce transportation costs, and minimize delays. Automated warehouse systems improve order fulfillment speed and accuracy. |

| Customer Service | Real-time tracking of orders and automated communication systems improve customer satisfaction and transparency. Data analysis can identify customer preferences and improve future product development. |

Future Trends and Innovations

The future of smart furniture manufacturing is poised for significant transformation, driven by the integration of cutting-edge technologies. This evolution promises to reshape not only the manufacturing process but also the design and user experience of furniture itself. Manufacturers are embracing advancements in artificial intelligence, the internet of things, and augmented/virtual reality, creating more personalized, adaptable, and efficient production lines.The integration of these technologies is fundamentally altering the landscape of furniture design and development.

The result is a greater focus on sustainability, personalization, and user-centric design, pushing the boundaries of what’s possible in the industry.

Potential of Emerging Technologies

Emerging technologies like AI, IoT, and AR/VR are poised to revolutionize smart furniture manufacturing. AI can optimize production processes, predict maintenance needs, and personalize user experiences. IoT networks enable real-time data collection and analysis, leading to more responsive and adaptable furniture designs. AR/VR technologies provide immersive design experiences, allowing users to visualize and interact with furniture in a virtual environment before it’s produced.

This innovative approach streamlines the design process and reduces design errors.

Future Furniture Design Applications

Smart furniture design will increasingly incorporate features like adaptable configurations, dynamic lighting, and integrated control systems. Furniture could adjust its configuration based on user needs or environmental conditions, optimizing space usage and comfort. Dynamic lighting systems can create personalized ambiances, enhancing the overall user experience. Furthermore, integration with home automation systems will become more prevalent, enabling seamless control over various aspects of the living space.

For example, adjustable desks that dynamically change height based on user posture or furniture that adjusts to accommodate different users in a family or home office are potential applications.

Impact on the Broader Design Industry

Smart furniture manufacturing will have a profound impact on the broader design industry. It will foster greater collaboration between designers, engineers, and manufacturers, leading to more innovative and user-friendly products. The emphasis on personalization and customization will encourage designers to think beyond traditional design parameters, exploring new possibilities and creating more unique and adaptable solutions. The increasing integration of technology will require designers to possess a broader skill set, incorporating technical expertise alongside artistic vision.

Emerging Technologies and Applications

- Artificial Intelligence (AI): AI-powered systems can optimize production processes, predict maintenance needs, and personalize user experiences. Examples include automated quality control systems, predictive maintenance models for furniture components, and personalized recommendations for furniture configurations.

- Internet of Things (IoT): IoT networks enable real-time data collection and analysis, leading to more responsive and adaptable furniture designs. Examples include smart tables that track user interactions and adjust their settings accordingly, and smart lighting systems that react to ambient conditions.

- Augmented Reality (AR) and Virtual Reality (VR): AR/VR technologies provide immersive design experiences, allowing users to visualize and interact with furniture in a virtual environment before it’s produced. This enables detailed visualization and user feedback integration before physical production, potentially reducing errors and design iterations.

- 3D Printing: 3D printing offers greater customization options for furniture design. This allows for the creation of complex shapes and intricate details, which were previously difficult or impossible to produce through traditional methods. Examples include custom-designed chair backs, intricate shelving designs, and highly personalized furniture pieces.

- Biometric Sensors: Biometric sensors can monitor user posture and movements, providing real-time feedback to optimize comfort and prevent injuries. This could lead to furniture designs that adapt to user needs, improving ergonomics and promoting health.

Market Analysis and Consumer Adoption

Source: behance.net

The smart furniture market is experiencing rapid growth, driven by evolving consumer preferences and technological advancements. Understanding current trends, consumer expectations, and diverse pricing and marketing strategies is crucial for success in this dynamic sector. This analysis will explore the factors influencing consumer adoption and the key strategies for tailoring smart furniture to specific market segments.

Current Market Trends for Smart Furniture

The smart furniture market is characterized by a rise in demand for integrated technology solutions. Consumers are increasingly seeking furniture that seamlessly blends functionality and aesthetics. This includes furniture with built-in connectivity for entertainment, lighting control, and environmental monitoring. The incorporation of IoT (Internet of Things) features and AI-powered automation is another prominent trend. This is evident in smart beds with adjustable features, tables that can adapt to different user needs, and integrated storage solutions.

Consumer Preferences and Expectations

Consumers are drawn to smart furniture for its convenience and enhanced functionality. A key expectation is intuitive and seamless integration of technology with the furniture design. Aesthetic appeal is also a significant factor. Smart furniture should not compromise on style and should complement the existing interior design. Consumers are increasingly prioritizing sustainability and eco-friendly materials, expecting manufacturers to incorporate environmentally conscious practices throughout the production process.

Pricing Strategies for Smart Furniture

Pricing strategies for smart furniture vary considerably. Premium models often command higher prices due to advanced features, premium materials, and sophisticated design. Mid-range products generally offer a balance between price and functionality, while budget-friendly options may incorporate basic smart features. Value-added services, such as extended warranties and remote technical support, can influence pricing decisions.

Marketing Strategies for Smart Furniture

Successful marketing strategies for smart furniture focus on highlighting the unique benefits and value proposition. Demonstrating the ease of use and intuitive design of the products is critical. Emphasis should be placed on showcasing the furniture’s integration with existing home technology systems. Targeted advertising campaigns and collaborations with interior designers and architects can significantly boost brand awareness and market penetration.

Tailoring Products to Specific Consumer Segments

Effective marketing requires tailoring products to meet the needs of specific consumer segments. For example, families may prioritize functionality and space-saving designs, while young professionals might seek modern and stylish solutions with integrated entertainment systems. Elderly individuals may appreciate assistive features and easy-to-use controls. Understanding the unique preferences of each segment allows for the creation of targeted marketing materials and product offerings.

Conclusive Thoughts

In conclusion, Smart Technology in Furniture Manufacturing presents a compelling vision for the future of furniture. The integration of technology across the entire supply chain, from design and manufacturing to logistics and consumer interaction, offers significant opportunities for increased efficiency, sustainability, and enhanced user experiences. As technology continues to advance, we can anticipate even more innovative and personalized furniture solutions in the years to come.

FAQ Summary

What are the main challenges in integrating smart technology into existing furniture manufacturing processes?

Integrating smart technology into existing processes can be challenging due to the need for significant investments in new equipment, training for personnel, and potentially restructuring the supply chain. Cost-effectiveness and compatibility with existing infrastructure are crucial considerations.

How does smart technology improve the sustainability of furniture manufacturing?

Smart technologies can improve sustainability by optimizing material use, reducing waste during production, and enabling more efficient logistics. Monitoring and controlling the manufacturing process can lead to lower energy consumption and reduced environmental impact.

What are the potential privacy concerns associated with data collected from smart furniture?

Data privacy and security are paramount in smart furniture manufacturing. Robust security measures are essential to protect user data and ensure responsible data handling practices. Transparency about data collection and usage is vital to building trust with consumers.

What is the role of AI in optimizing inventory management for smart furniture?

AI can analyze sales data, predict demand fluctuations, and optimize inventory levels, reducing waste and ensuring efficient stock management. This contributes to cost reduction and increased profitability.