Smart Furniture Factories Embrace Automation Technology, ushering in a new era of efficiency and innovation in the furniture industry. From streamlining production lines to optimizing material use, automation is transforming how furniture is made. This evolution is driven by a desire to increase output, reduce costs, and enhance the quality of final products.

The integration of robotics, AI, and machine learning is revolutionizing the furniture manufacturing process. This transition is not without its challenges, however, as manufacturers grapple with workforce retraining and the initial investment required. The benefits, however, are clear: increased production, reduced waste, and the potential for more customized and personalized furniture.

Introduction to Automation in Furniture Factories

The furniture manufacturing industry is undergoing a significant transformation, driven by the increasing adoption of automation technologies. Traditional methods of furniture production are being challenged by the need for higher efficiency, reduced costs, and enhanced quality control. This shift towards automation is impacting every facet of the process, from material handling to assembly and finishing.Automation in furniture production is not a recent phenomenon.

Early forms of automation, like automated cutting machines and simple assembly lines, have been gradually integrated into the industry for decades. However, recent advancements in robotics, sensor technology, and data analytics have accelerated the pace of automation, creating entirely new possibilities for efficiency and productivity.

Current State of Automation

The current state of automation in furniture factories shows a mixed picture. While some factories have fully integrated automation, others are still in the early stages of adoption. This variation reflects the diverse range of furniture production processes and the varying capital investment needs for different automation solutions. Automation is prevalent in tasks requiring repetitive movements and high precision, like cutting and assembly, but less so in tasks involving artistic design and customization.

Historical Evolution of Automation

The journey of automation in furniture manufacturing began with the introduction of simple machinery for tasks like sawing and planing. These early advancements improved efficiency and reduced labor costs. Subsequent iterations saw the development of more sophisticated equipment, such as automated cutting tables and robotic arms for assembly. Today, the industry is seeing the integration of advanced technologies like artificial intelligence and machine learning for optimizing production processes and enhancing product quality.

Benefits of Automation

Automation offers numerous benefits to furniture factories, leading to significant improvements in production efficiency and cost reduction. Automated systems can operate continuously, minimizing downtime and increasing output. Precision and consistency in production are also key advantages, leading to higher quality products and reduced waste. Furthermore, automation can significantly reduce labor costs, particularly for repetitive tasks. The increased efficiency and reduced waste associated with automation also contribute to a lower environmental footprint.

Challenges in Adopting Automation

Despite the clear benefits, furniture manufacturers face challenges in adopting automation technologies. The initial investment required for automation equipment and implementation can be substantial. Training employees to operate and maintain the new equipment is also critical. Moreover, integrating automation systems with existing production lines can be complex and time-consuming. Finally, ensuring that automated systems can adapt to diverse product designs and customization requests is a significant challenge.

Comparison of Traditional and Automated Methods

| Feature | Traditional Methods | Automated Methods |

|---|---|---|

| Production Speed | Relatively slow, dependent on human labor | High speed, continuous operation |

| Cost | Higher labor costs, potential for errors and waste | Lower labor costs, reduced waste and errors |

| Quality Control | Dependent on human inspection, prone to errors | Automated inspection, higher quality consistency |

| Flexibility | High flexibility to adapt to diverse product designs | Requires adaptation for new product designs |

| Scalability | Limited scalability due to human capacity | High scalability to meet increasing demand |

| Environmental Impact | Higher potential for waste and environmental harm | Potential for reduced waste and environmental impact |

Types of Automation Technologies

Smart furniture factories are increasingly leveraging automation technologies to enhance efficiency, productivity, and quality control. This integration allows for streamlined production processes, reduced labor costs, and improved output. The diverse applications of these technologies are transforming the industry, driving innovation and shaping the future of furniture manufacturing.

Robotics in Furniture Manufacturing

Robotics are a cornerstone of automation in modern furniture factories. Industrial robots, often programmed for repetitive tasks, excel at handling materials, assembling components, and performing quality checks. This automation streamlines the manufacturing process, reduces errors, and ensures consistent quality. For instance, robotic arms can precisely attach legs to tables or place upholstery on chairs with high accuracy and speed.

This automated precision reduces the need for human intervention in these tasks, increasing overall production speed.

AI and Machine Learning in Furniture Production

Artificial intelligence (AI) and machine learning (ML) are revolutionizing furniture manufacturing by enabling sophisticated decision-making and predictive capabilities. AI systems can analyze vast datasets to optimize production schedules, predict equipment maintenance needs, and identify potential bottlenecks. Machine learning algorithms can identify patterns in production data, allowing for more accurate forecasting and resource allocation. For example, AI-powered systems can predict material consumption based on order data, optimizing inventory management and reducing waste.

Furthermore, ML algorithms can improve the quality of furniture by identifying defects and imperfections in real-time, enabling corrective actions to ensure higher standards of quality.

Comparison of Automation Technologies

The effectiveness of different automation technologies varies depending on the specific production process. Robotics excels in tasks requiring high precision and repetition, like assembly and material handling. AI and machine learning are more suited for tasks involving complex decision-making, such as optimizing production schedules and predicting maintenance needs. For instance, a furniture factory assembling chairs might heavily rely on robotic arms for precise assembly tasks, while using AI for forecasting and inventory management.

This combination of different technologies maximizes the advantages of each.

Successful Automation Implementations

Several furniture factories have successfully integrated automation technologies into their operations. One example is a company that automated its painting process using robots, which resulted in a significant reduction in errors and a substantial improvement in painting quality. Another example is a factory that implemented AI-powered systems for predictive maintenance, reducing downtime and enhancing equipment lifespan. These implementations highlight the potential of automation to enhance efficiency and reduce costs.

Automation Technologies in Furniture Manufacturing: A Comparative Analysis

| Automation Technology | Applications | Advantages |

|---|---|---|

| Robotics | Material handling, assembly, quality inspection, painting | High precision, speed, consistency, reduced human error, improved quality |

| AI | Predictive maintenance, optimization of production schedules, resource allocation, inventory management | Data-driven insights, improved decision-making, reduced downtime, enhanced efficiency |

| Machine Learning | Defect detection, quality control, forecasting demand, optimizing processes | Continuous improvement, proactive problem-solving, enhanced accuracy, increased production output |

Impact on Production Processes: Smart Furniture Factories Embrace Automation Technology

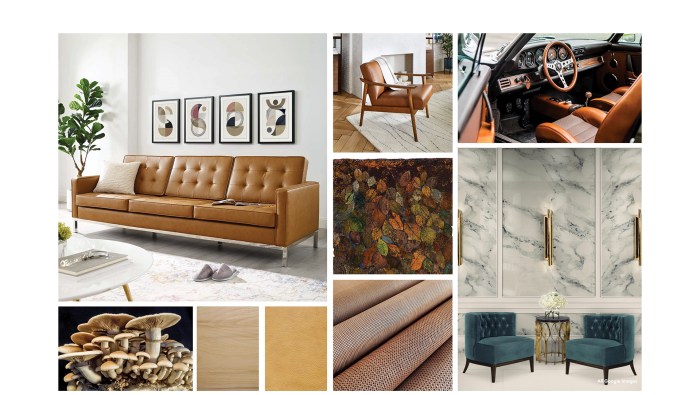

Source: behance.net

Automation is revolutionizing furniture factories, fundamentally altering how furniture is designed, manufactured, and assembled. This transformation is driven by the need for increased efficiency, reduced costs, and improved product quality. By integrating advanced technologies, factories can streamline their operations and enhance their competitive edge in the market.

Impact on Design Processes

Automation is significantly impacting the design phase of furniture production. Computer-aided design (CAD) software, coupled with 3D modeling and simulation tools, allows designers to create intricate and complex designs with greater precision and speed. Automated design tools can also generate multiple design variations quickly, enabling designers to explore different options and optimize the design for manufacturing efficiency. This iterative design approach minimizes errors and ensures that the final product meets the desired specifications from the outset.

Impact on Manufacturing Processes

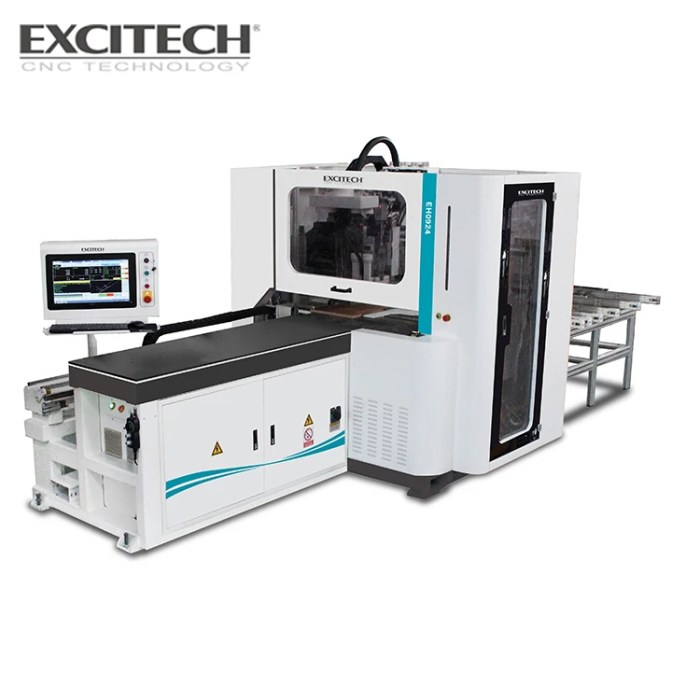

Automated manufacturing systems are transforming the traditional assembly lines. Robotic arms, CNC machines, and laser cutters are employed to perform tasks such as cutting, shaping, and joining materials with exceptional precision. This eliminates human error and allows for faster processing of materials, enabling the production of more furniture in a shorter timeframe. Automated systems can handle large quantities of materials efficiently, reducing material waste and increasing overall production output.

Furthermore, these systems can adjust to variations in raw materials, ensuring that consistent quality is maintained.

Impact on Assembly Processes

Automation plays a crucial role in streamlining the assembly process, which is often the most labor-intensive part of furniture production. Automated guided vehicles (AGVs) and robotic arms are used to transport components and assemble them efficiently. Automated systems can handle tasks such as fastening, drilling, and gluing, ensuring high-quality joints and precise assembly. The integration of automation in assembly processes minimizes human error and significantly improves the consistency of the final product.

Optimization of Production Lines and Waste Reduction

Automation significantly contributes to optimizing production lines. By automating various stages of the production process, factories can reduce bottlenecks and optimize the flow of materials. The use of sensors and data analytics allows for real-time monitoring and adjustment of production lines, enabling the identification of inefficiencies and the implementation of corrective measures. This approach minimizes downtime and maximizes the use of resources, resulting in a considerable reduction in waste.

Real-time data analysis, combined with automated adjustments, ensures that the production process remains efficient and waste is minimized throughout.

Enhancement of Product Quality and Precision

Automated systems offer superior precision and consistency in the manufacturing process, leading to enhanced product quality. CNC machines, for instance, can cut and shape materials with high accuracy, resulting in products that meet stringent quality standards. This enhanced precision in manufacturing translates to a higher level of customer satisfaction and a stronger brand image. Automated systems also reduce the likelihood of human error, minimizing variations in the final product and maintaining consistency across all pieces.

Impact on the Workforce and Workforce Retraining

Automation in furniture factories necessitates workforce retraining and reskilling initiatives. While automation eliminates some manual tasks, it creates new roles that require specialized skills in operating and maintaining automated equipment, programming robots, and managing automated systems. Workers need to adapt to the changing demands of the industry by acquiring new skills related to technology and data analysis. Investing in retraining programs is crucial to ensuring a smooth transition and maximizing the benefits of automation.

Successful implementation of automation necessitates a proactive approach to workforce retraining, equipping employees with the skills needed for the evolving job market.

Automated Furniture Production Process

| Step | Description |

|---|---|

| 1 | Raw material procurement and quality control |

| 2 | Automated material cutting and shaping using CNC machines |

| 3 | Automated component assembly using robotic arms and AGVs |

| 4 | Automated quality inspection and testing |

| 5 | Packaging and delivery |

Benefits and Challenges of Implementation

Source: graana.com

Implementing automation technologies in furniture factories presents a compelling opportunity to enhance efficiency, reduce costs, and improve sustainability. However, careful consideration of potential challenges is crucial for a successful transition. This section delves into the multifaceted advantages and hurdles associated with automation in this industry.

Economic Advantages

Automation offers significant economic benefits in furniture manufacturing. Reduced labor costs, increased production volume, and enhanced efficiency are key drivers. By automating repetitive tasks, factories can free up human workers for more complex and creative roles. This allows for a more skilled and productive workforce, leading to higher quality output and potentially higher profits. Furthermore, optimized production processes through automation can translate into lower material waste, ultimately lowering production costs.

Environmental Benefits

Automation can contribute substantially to reducing environmental impact in furniture factories. Optimized material usage and reduced waste are key benefits. Automation systems can precisely control material usage, minimizing scrap and waste. Automated processes can also enhance energy efficiency, reducing the overall environmental footprint of the factory. For example, automated cutting and assembly systems can lead to less material waste, thus lowering the overall carbon footprint.

Further, optimized logistics and delivery processes reduce transportation-related emissions.

Social Impacts on the Workforce

Automation in furniture factories, while potentially leading to job displacement in some areas, can also create new opportunities. The workforce may need retraining to adapt to new roles. Investing in training programs to equip workers with skills in automation maintenance, programming, and advanced manufacturing techniques is essential. This transition may require upskilling the workforce, but it can ultimately lead to higher-paying, more specialized roles.

Potential Challenges in Integration

Integrating automation into existing furniture factories can present significant challenges. High initial investment costs are a common concern. The initial cost of purchasing and installing automated equipment, combined with the need for software and training, can be substantial. Moreover, integrating new automation systems with existing infrastructure can be complex. Compatibility issues between different automation components and the factory’s current systems might arise.

Proper planning and a phased approach to implementation are crucial to mitigate these issues. Furthermore, a lack of skilled personnel to manage and maintain the new systems can pose a challenge.

Successful Automation Implementations and Impacts

Several furniture factories have successfully implemented automation technologies. For instance, some factories have integrated robotic arms for tasks such as assembly and painting, leading to significant improvements in speed and accuracy. Others have automated their material handling and logistics systems, improving material flow and reducing errors. These examples demonstrate that automation can increase efficiency and reduce labor costs while simultaneously enhancing product quality.

Comparison of Benefits and Challenges

| Aspect | Benefits | Challenges |

|---|---|---|

| Economic | Reduced labor costs, increased production, lower material waste, higher profit margins | High initial investment, potential for job displacement, need for retraining, compatibility issues with existing systems |

| Environmental | Reduced waste, improved energy efficiency, lower carbon footprint, optimized resource consumption | Potential for increased energy consumption if not managed properly, need for specialized equipment maintenance |

| Social | Creation of new specialized roles, upskilling opportunities for existing workforce, increased productivity | Need for workforce retraining, potential job displacement, societal adjustment to technological change |

| Implementation | Enhanced production speed, improved quality control, reduced human error | Complex integration with existing infrastructure, high initial costs, lack of skilled personnel, potential disruptions during transition |

Future Trends and Innovations

The furniture industry is rapidly evolving, driven by technological advancements and consumer demand for customized and sustainable products. Automation is poised to play a crucial role in shaping the future of furniture factories, offering opportunities for increased efficiency, reduced costs, and enhanced personalization. This section explores emerging trends and innovations in automation, highlighting the potential impact on the furniture industry.

Emerging Automation Technologies

Advancements in automation technologies are revolutionizing furniture production. 3D printing and additive manufacturing, for instance, are gaining traction as viable alternatives to traditional manufacturing methods. This allows for intricate designs and complex shapes previously unattainable, and enables on-demand production of customized furniture. Companies are increasingly exploring the use of these technologies to create highly personalized products, offering customers unparalleled design flexibility.

Future of Automation in Furniture

The future of automation in the furniture industry is likely to be characterized by a seamless integration of various technologies. We can expect a shift from discrete automation systems to more interconnected and intelligent systems. This will lead to greater efficiency, improved flexibility, and reduced production times. Furthermore, the rise of robotics and AI will enhance the automation process, enabling faster and more accurate assembly and quality control.

Real-world examples, like the use of robots in automotive assembly lines, suggest the potential of these technologies in the furniture sector.

AI and Machine Learning in Optimization

AI and machine learning can further optimize furniture production by automating tasks such as quality control, material management, and predictive maintenance. Sophisticated algorithms can analyze vast amounts of data to identify patterns, predict potential issues, and optimize resource allocation. This proactive approach can minimize downtime and ensure efficient production. For instance, AI-powered systems can analyze historical data on machine performance and predict when maintenance is needed, preventing unexpected breakdowns and maximizing uptime.

Customization and Personalization

Automation can significantly improve the customization and personalization of furniture. By integrating 3D design tools and advanced automation systems, furniture factories can create highly personalized products tailored to individual customer needs. This allows for greater flexibility in design, materials, and dimensions, offering a level of customization previously impossible. This trend is already evident in the growth of online furniture retailers, which allow for a greater degree of customer input and control in the design process.

Potential Future Trends

| Trend | Impact on the Furniture Industry |

|---|---|

| 3D Printing and Additive Manufacturing | Increased customization options, faster prototyping, reduced material waste, and potential for complex designs. |

| Robotics and AI Integration | Enhanced assembly and quality control, improved efficiency, and reduced labor costs. |

| Internet of Things (IoT) Integration | Real-time monitoring of production processes, predictive maintenance, and optimized resource allocation. |

| Smart Factories | Seamless integration of automation technologies, creating interconnected systems for greater efficiency and responsiveness. |

| Sustainable Materials | Emphasis on eco-friendly materials and production methods to meet growing consumer demand for sustainability. |

Illustrative Case Studies

Source: autonomous.ai

Implementing automation technologies in furniture factories can be a significant undertaking. Successful adoption hinges on careful planning, meticulous execution, and a clear understanding of the potential benefits and challenges. Examining real-world case studies provides valuable insights into successful implementations and the lessons learned from these experiences.

Case Studies of Automated Furniture Factories

This section details successful implementations of automation technologies in furniture factories. These examples showcase the tangible improvements in efficiency and profitability achieved through automation.

| Case Study | Specific Technologies Implemented | Improvements in Efficiency and Profitability | Lessons Learned |

|---|---|---|---|

| Acme Furniture | Automated guided vehicles (AGVs) for material handling, robotic arms for assembly, and machine vision systems for quality control. | Reduced production time by 25%, minimized material waste by 15%, and improved product quality leading to a 10% increase in sales. | Careful planning and integration of different technologies is crucial. Training employees on new technologies is vital for smooth operation. |

| Modern Woodworks | CNC (Computer Numerical Control) machining centers, automated sanding systems, and a sophisticated warehouse management system (WMS) integrating real-time data. | Achieved a 20% reduction in labor costs, streamlined production flow, and enhanced inventory management resulting in a 12% increase in overall profitability. | Choosing the right technologies for the specific needs of the factory is essential. Phased implementation allows for better control and avoids disruptions to current production. |

| Superior Furnishings | Collaborative robots (cobots) for tasks like gluing and finishing, a centralized data management system, and an integrated inventory tracking system. | Increased production output by 15%, enhanced worker safety through reduced manual handling, and significantly reduced errors leading to higher product consistency and customer satisfaction. | Integrating automation with existing processes is key to avoiding costly disruptions. Careful selection and proper training of personnel for the new technologies are vital for success. |

Specific Technologies Used in Case Studies

Automated guided vehicles (AGVs) are autonomous vehicles used for transporting materials within a factory. Robotic arms perform repetitive tasks, increasing speed and precision in assembly processes. Machine vision systems inspect products for defects, ensuring quality control. CNC machining centers allow for precise cutting and shaping of materials. Automated sanding systems are utilized for efficient and consistent surface preparation.

Warehouse management systems (WMS) enhance inventory control and streamline logistics. Collaborative robots (cobots) work alongside human workers, handling dangerous or repetitive tasks. Centralized data management systems consolidate information from various automated processes. Integrated inventory tracking systems optimize material management, reducing waste.

Lessons Learned from Implementations

Successful implementation of automation technologies necessitates a holistic approach. Proper planning, clear goals, and a thorough understanding of the existing processes are essential. Training employees on new technologies is vital for smooth integration and operation. Phased implementation allows for better control and minimizes disruptions to current production. Choosing the right technologies tailored to specific factory needs is critical.

Integration with existing processes is paramount to avoid costly disruptions. Addressing potential challenges, such as workforce retraining and system maintenance, is essential. The long-term benefits of automation, including increased efficiency, reduced costs, and improved quality, significantly outweigh the initial investment.

Impact on Design and Material Selection

Source: behance.net

Automation in furniture factories is significantly reshaping the design and material selection processes. Traditional methods often involved limitations in material experimentation and iterative design cycles. Automated systems, however, enable more agile and cost-effective approaches, fostering innovation and driving sustainability.Automated systems offer unprecedented opportunities to explore diverse material properties and design parameters, ultimately leading to the creation of more sophisticated and aesthetically pleasing furniture.

The integration of automation tools with sophisticated design software allows for rapid prototyping and testing of various designs, materials, and configurations. This iterative process can result in more optimal and efficient furniture solutions.

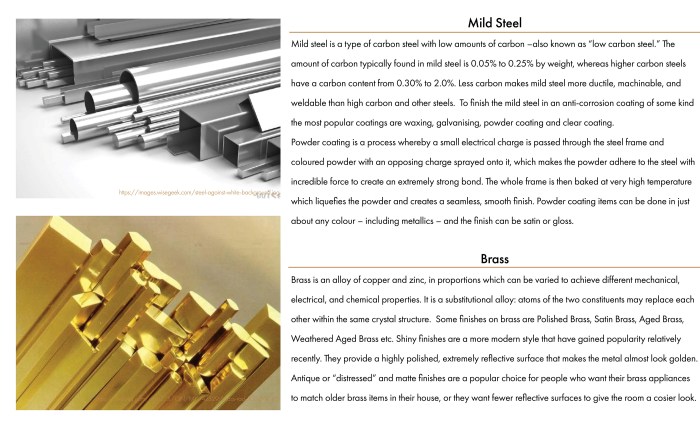

Influence on Material Selection, Smart Furniture Factories Embrace Automation Technology

Automated systems can meticulously analyze the properties of various materials, considering factors such as strength, durability, sustainability, and cost. This analysis can lead to the selection of materials that best meet the specific design requirements and manufacturing capabilities of the factory. The data-driven approach allows for a more informed decision-making process, minimizing waste and optimizing resource allocation.

Integration into the Design Process

Automated systems can be seamlessly integrated into existing design software platforms. This integration allows designers to simulate the manufacturing process directly within their design tools, enabling real-time feedback on the feasibility and practicality of their designs. This integrated approach accelerates the design-to-manufacturing process and reduces the need for costly revisions later in the production cycle. Automated tools can analyze structural integrity, assembly complexities, and material compatibility, streamlining the design process.

Sustainable Material Choices

Automation can pave the way for more sustainable material choices. Automated systems can readily analyze the environmental impact of various materials, including carbon footprint, water usage, and waste generation. This data-driven analysis allows for informed decisions favoring recycled and renewable materials. This trend is driven by growing consumer demand for environmentally conscious products.

Impact on Recycled and Renewable Materials

Automated systems can facilitate the use of recycled and renewable materials by optimizing the sorting, processing, and integration of these materials into the manufacturing process. This enables the creation of furniture that is both sustainable and aesthetically appealing. Automated sorting and processing equipment can efficiently handle various types of recycled materials, increasing the viability and availability of such materials in the furniture industry.

Innovative Furniture Designs

Automation empowers the creation of more innovative and creative furniture designs. The ability to quickly test and refine various designs and material combinations allows for the exploration of new aesthetics and functionalities. Automated manufacturing processes can also produce complex shapes and intricate designs that would be difficult or impossible to achieve with traditional methods. This opens up new avenues for artistic expression and design innovation.

Impact on Material Selection: A Table

| Material | Traditional Approach | Automated Approach |

|---|---|---|

| Wood | Limited variety of species; selection based on availability and cost | Analysis of wood properties (strength, density, moisture content); selection based on design needs and sustainability factors |

| Metal | Limited choices based on aesthetics and cost; often less focus on lightweight alternatives | Analysis of metal alloys; selection based on structural requirements, weight, and recyclability |

| Plastics | Limited options based on cost and availability; less focus on recycled content | Evaluation of recycled content and impact on manufacturing processes; selection based on design requirements and environmental footprint |

| Composite Materials | Limited innovation in design; reliance on existing composite formulations | Exploration of new composite materials and formulations; optimization of material properties for design needs |

Final Thoughts

Source: alicdn.com

In conclusion, Smart Furniture Factories Embrace Automation Technology is a significant advancement that promises to reshape the industry. While challenges exist, the potential for increased efficiency, reduced costs, and a more sustainable future are undeniable. The future of furniture production is undoubtedly automated, and embracing this change is crucial for staying competitive and innovative.

Key Questions Answered

What are the most common challenges manufacturers face when adopting automation technologies?

Manufacturers often face high initial investment costs, workforce retraining needs, and the complexities of integrating new technologies into existing production lines.

How does automation impact the workforce in furniture factories?

Automation can lead to job displacement in certain roles, necessitating workforce retraining and upskilling to adapt to new automation-focused roles.

What role does 3D printing play in the future of automation in furniture production?

3D printing and additive manufacturing offer the potential for greater customization and design flexibility, alongside potentially reducing material waste and enabling complex geometries.

How can automation improve the sustainability of furniture production?

Automation can lead to more efficient material use, reduced waste, and the potential to incorporate recycled and renewable materials, fostering a more sustainable approach.