Smart Factories in Furniture Production: Embracing Industry 4.0 Technologies presents a compelling vision for the future of furniture manufacturing. This transformative approach leverages cutting-edge technologies to optimize every stage of the process, from design to delivery. The transition from traditional methods to smart factories promises increased efficiency, reduced costs, and a greater emphasis on customization. Companies are already adopting these innovative strategies, and the results are reshaping the industry.

The core of this revolution lies in the integration of technologies like IoT, AI, and automation. These tools enable real-time data collection, predictive maintenance, and automated processes. Furthermore, data analytics plays a critical role in optimizing production flows and identifying areas for improvement. This shift towards a more data-driven approach ultimately translates to higher quality products, quicker turnaround times, and more responsive production cycles.

Introduction to Smart Factories in Furniture Production

Source: co.za

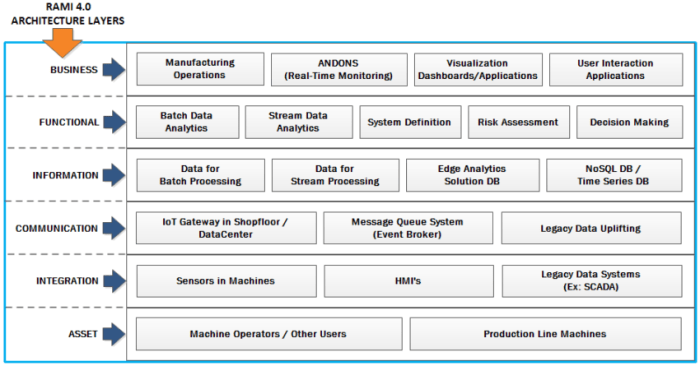

Smart factories in furniture production represent a significant evolution from traditional methods, leveraging digital technologies to enhance efficiency, productivity, and customization. These factories utilize advanced automation, data analytics, and interconnected systems to optimize every stage of the manufacturing process, from design to delivery. This shift toward smart manufacturing allows furniture companies to respond rapidly to market demands and customer preferences.The core principles of Industry 4.0 technologies, applicable to furniture manufacturing, revolve around interconnected systems, data-driven decision-making, and real-time monitoring.

These technologies include advanced robotics, 3D printing, Internet of Things (IoT) sensors, and sophisticated software for process control and data analysis. These tools enable manufacturers to gather and analyze vast amounts of data to identify bottlenecks, predict maintenance needs, and optimize resource allocation.

Evolution of Furniture Production Processes

Traditional furniture production often relied on manual labor and relatively simple machinery. Processes were frequently isolated, leading to delays and inefficiencies. The shift to smart factories marks a transition from these fragmented, manual processes to integrated, automated systems. This evolution encompasses the digitization of design and manufacturing, enabling real-time tracking of materials, components, and finished products. It also fosters greater flexibility and responsiveness to customer demands.

Examples of Furniture Companies Adopting Industry 4.0 Technologies

Several furniture companies have embraced Industry 4.0 technologies to enhance their operations. For example, [Company A], a leading European furniture manufacturer, has implemented robotic arms for automated assembly lines, significantly reducing production time and improving quality control. Another example is [Company B], a US-based company, utilizing IoT sensors to monitor the condition of machinery in real-time, enabling proactive maintenance and minimizing downtime.

These are just a few examples, and many more companies are exploring and adopting Industry 4.0 technologies to gain a competitive edge in the global market.

Comparison of Traditional and Smart Furniture Factories

| Feature | Traditional Furniture Factory | Smart Furniture Factory |

|---|---|---|

| Production Process | Manual, fragmented, reliant on human labor; processes are often isolated. | Automated, integrated, utilizing advanced robotics and digital systems; processes are interconnected. |

| Data Management | Limited data collection and analysis; data is often not integrated across different stages. | Extensive data collection from various sources; real-time data analysis for informed decision-making. |

| Customization | Limited customization options; often batch-oriented production. | High degree of customization; agile production adapting to individual customer needs. |

| Efficiency | Lower efficiency due to manual processes and potential bottlenecks. | Higher efficiency due to automation and real-time optimization. |

| Flexibility | Lower flexibility to adapt to changing market demands. | Higher flexibility to adjust production schedules and respond to customer needs rapidly. |

This table highlights the key differences between traditional and smart furniture factories, showcasing the advantages of adopting Industry 4.0 technologies.

Key Technologies Driving Smart Furniture Factories

Source: co.in

Smart furniture factories are leveraging cutting-edge technologies to optimize production processes, enhance product quality, and cater to increasing customer demands for customization. These technologies, collectively known as Industry 4.0, are transforming the furniture industry from a traditional, manual-based system to a digitally driven, highly efficient model. This shift allows for greater flexibility, responsiveness, and overall profitability.

Internet of Things (IoT)

The Internet of Things (IoT) plays a pivotal role in connecting various components of a furniture factory, from raw material tracking to finished product monitoring. This connectivity enables real-time data collection and analysis, offering valuable insights into production efficiency and potential bottlenecks. Sensors embedded in machines, materials, and even individual products provide a constant stream of data, fostering proactive maintenance and optimization.

For instance, smart sensors can detect anomalies in machine performance, enabling predictive maintenance and minimizing downtime.

Artificial Intelligence (AI)

Artificial intelligence (AI) is revolutionizing furniture production through automation and intelligent decision-making. AI-powered systems can analyze vast amounts of data to identify patterns, predict potential issues, and optimize production schedules. For example, AI algorithms can analyze customer design preferences and predict popular product configurations, allowing factories to preemptively adjust production lines. Furthermore, AI-driven quality control systems can detect defects with greater accuracy and speed than traditional methods, minimizing waste and ensuring high-quality products.

Big Data Analytics

Big data analytics provides a comprehensive view of the entire furniture production process, enabling factories to gain deeper insights into operational performance. By analyzing data from various sources, such as machine logs, sensor readings, and customer feedback, factories can identify areas for improvement, predict future trends, and optimize production processes. For example, analyzing sales data can identify popular design trends, allowing factories to adjust production plans accordingly.

Real-time data analysis can identify bottlenecks and inefficiencies, leading to optimized workflows and improved productivity.

Automation

Automation, encompassing robotics and automated guided vehicles (AGVs), is crucial for enhancing efficiency and precision in furniture manufacturing. Automated systems can handle repetitive tasks, such as material handling, assembly, and finishing, with high accuracy and speed. This not only increases output but also reduces human error, ensuring higher product quality. For instance, robotic arms can precisely assemble complex furniture pieces, improving consistency and accuracy in assembly.

Automated systems can also optimize material flow, minimizing wasted time and resources.

Table: Applications of Technologies in Furniture Production

| Technology | Application | Impact on Efficiency | Impact on Quality | Impact on Customization |

|---|---|---|---|---|

| IoT | Real-time tracking of raw materials, production processes, and finished products. | Improved process monitoring, predictive maintenance, reduced downtime. | Enhanced quality control through early defect detection. | Facilitates customized production by enabling dynamic adjustments based on real-time data. |

| AI | Predictive maintenance, automated quality control, optimized production scheduling, design trend analysis. | Reduced downtime, optimized resource allocation. | Increased accuracy and consistency in product quality. | Personalized design suggestions, quicker customization response. |

| Big Data | Analysis of sales data, customer feedback, machine logs, sensor readings. | Identification of bottlenecks and inefficiencies, optimized production schedules. | Improved quality control by identifying patterns in defects. | Targeted marketing and improved customization options based on data insights. |

| Automation | Robotic assembly, automated material handling, automated finishing. | Increased production output, reduced labor costs. | Improved consistency and accuracy in manufacturing processes. | Allows for rapid prototyping and customized assembly lines. |

Data Analytics in Optimizing Furniture Production

Data analytics plays a crucial role in optimizing furniture production processes. By analyzing data from various sources, factories can identify bottlenecks, predict potential issues, and make informed decisions to improve efficiency and quality. Analyzing historical production data reveals trends and patterns, allowing factories to optimize workflows and predict future needs. Predictive analytics based on data analysis can proactively address potential problems, preventing delays and minimizing disruptions.

Impact on Furniture Production Processes

Smart factory technologies are revolutionizing furniture production, impacting every stage from initial design to final delivery. These technologies offer a multifaceted approach, improving efficiency, quality, and responsiveness to customer demands across diverse production models. Implementing these advancements allows furniture manufacturers to adapt to changing market conditions and consumer preferences more swiftly.

Design Stage

Digital design tools, 3D modeling software, and collaborative platforms are transforming the design process. Designers can easily iterate on designs, share revisions, and receive feedback in real-time, shortening the design cycle and reducing errors. This leads to more efficient design iterations and quicker product development cycles. Virtual prototyping, enabled by 3D printing and simulation software, allows for comprehensive testing and validation of designs before physical production begins, minimizing costly rework.

Manufacturing Stage

Smart manufacturing technologies like advanced robotics, automated guided vehicles (AGVs), and Internet of Things (IoT) sensors significantly improve efficiency and precision in the manufacturing process. Automated assembly lines, equipped with machine vision systems, can accurately track parts and ensure quality control throughout the production stages. Real-time data analytics enable predictive maintenance, allowing for proactive problem-solving and minimizing unplanned downtime.

Furthermore, automated quality checks and inspection systems enhance the precision of the finished product, leading to fewer defects and higher quality.

Logistics Stage

Smart logistics solutions, including real-time tracking, inventory management systems, and optimized delivery routes, enhance the efficiency of the entire supply chain. This allows for faster delivery times, reduced transportation costs, and better inventory management. Predictive analytics can forecast demand fluctuations and adjust inventory levels accordingly, reducing waste and ensuring timely product delivery. Furthermore, automated warehousing and order fulfillment systems enhance speed and accuracy in order processing.

Impact on Different Furniture Production Models, Smart Factories in Furniture Production: Embracing Industry 4.0 Technologies

The impact of smart factory technologies varies across different production models. Mass production benefits from increased automation and efficiency gains. Custom production, while potentially impacted by the same technologies, benefits more from increased agility and personalization capabilities. For example, personalized furniture orders can be tracked and manufactured with precision, minimizing errors and maximizing customization.

Predictive Maintenance

Predictive maintenance, utilizing sensor data and machine learning algorithms, allows for proactive maintenance schedules. By analyzing equipment performance data, factories can anticipate potential failures and schedule maintenance before they occur, reducing unplanned downtime and associated costs. For instance, if a machine is showing signs of impending failure, predictive maintenance systems can trigger a maintenance alert, allowing for timely repairs and avoiding significant production disruptions.

Potential Risks and Challenges

| Risk/Challenge | Description |

|---|---|

| High Initial Investment | Implementing smart factory technologies requires substantial upfront capital expenditure for new equipment and software. |

| Data Security and Privacy | Protecting sensitive data generated by connected machines and systems is crucial. |

| Integration Complexity | Integrating new technologies with existing systems can be complex and require significant expertise. |

| Skill Gaps | Training employees to operate and maintain new technologies is essential. |

| Cybersecurity Threats | Connected systems are vulnerable to cyberattacks. |

| Maintenance and Support | Ongoing maintenance and support for complex systems can be costly. |

Benefits and Challenges of Smart Furniture Factories

Smart furniture factories, leveraging Industry 4.0 technologies, promise significant improvements in efficiency and quality. However, implementation isn’t without its hurdles. This section delves into the potential advantages, the obstacles encountered, and the necessary skillsets required for a successful transition.Implementing smart factory solutions presents a complex undertaking for furniture manufacturers. Understanding the intricacies of both the benefits and challenges is crucial for informed decision-making.

The potential for increased productivity, reduced costs, and improved quality is substantial, but careful consideration of the associated obstacles is equally vital.

Potential Benefits of Smart Factories

Furniture manufacturers can anticipate substantial benefits from integrating smart factory technologies. These include optimized production processes, improved product quality, and reduced operational costs. Real-time data analysis empowers informed decisions regarding resource allocation and production scheduling.

- Increased Productivity: Automated systems and data-driven insights enable streamlined workflows, reducing downtime and optimizing resource allocation. This translates to a higher output of finished products.

- Reduced Costs: Minimizing waste, optimizing material usage, and reducing labor costs through automation lead to significant cost savings in the long run. Predictive maintenance also minimizes unexpected breakdowns.

- Improved Quality: Real-time monitoring and quality control measures ensure consistent product quality and reduce defects. This enhances customer satisfaction and brand reputation.

Challenges of Implementing Smart Factories

Despite the enticing benefits, several challenges accompany the adoption of smart factory technologies in furniture production. These include high initial investment costs, the need for skilled labor, and potential disruptions to existing workflows.

- High Initial Investment Costs: Implementing smart factory solutions requires substantial upfront investments in new technologies, software, and infrastructure. The return on investment (ROI) can take time to materialize.

- Integration Complexity: Integrating diverse systems and technologies can be complex and time-consuming. Existing systems might not be compatible with new technologies, necessitating significant modifications.

- Data Security Concerns: The increasing reliance on data creates concerns about security and privacy. Robust cybersecurity measures are crucial to protect sensitive information.

- Skill Gaps and Training Needs: Implementing smart factories necessitates a workforce equipped with the necessary technical skills to operate and maintain the new technologies. Training programs must be implemented to bridge skill gaps.

Required Skills and Training

A successful transition to a smart factory requires a workforce with diverse skills. This includes expertise in data analysis, automation systems, and cybersecurity. Formal training programs are essential to equip employees with the necessary competencies.

- Data Analysis: Employees need to understand how to interpret data from various sources to identify areas for improvement in production processes. Training on data analysis tools and techniques is essential.

- Automation Systems: Knowledge of automated systems, robotics, and programmable logic controllers (PLCs) is vital. Hands-on training and practical experience are necessary.

- Cybersecurity: Protecting sensitive data is paramount. Training in cybersecurity best practices, including data encryption and access control, is essential for maintaining data integrity.

Cost-Benefit Analysis of Smart Factory Solutions

A comparative analysis of various smart factory solutions can be presented in a table. This table considers the initial investment, ongoing maintenance costs, and anticipated benefits such as increased productivity and reduced waste.

| Smart Factory Solution | Initial Investment | Ongoing Maintenance Costs | Potential Benefits (e.g., Increased Productivity, Reduced Waste) |

|---|---|---|---|

| Automated Assembly Line | High | Moderate | Significant increase in production speed and quality |

| Real-time Inventory Management System | Moderate | Low | Reduced inventory costs and improved supply chain efficiency |

| Predictive Maintenance System | Moderate | Low | Minimized equipment downtime and improved maintenance planning |

Factors Influencing Adoption Rate

Several factors influence the rate at which furniture manufacturers adopt smart factory technologies. These include the industry’s overall economic climate, the availability of skilled labor, and the perceived ROI of these technologies.

- Economic Climate: A strong economic climate typically encourages investment in new technologies, fostering faster adoption rates. Conversely, economic downturns might lead to postponements of such investments.

- Availability of Skilled Labor: A readily available pool of skilled workers in data analysis, automation, and cybersecurity is crucial for smooth implementation. A shortage of skilled labor can hinder the adoption rate.

- Perceived ROI: A clear understanding of the return on investment (ROI) is a key driver for adoption. Demonstrating quantifiable benefits through case studies or pilot projects is crucial.

Future Trends and Developments

Source: org.uk

The furniture manufacturing landscape is poised for significant transformation, driven by the integration of advanced technologies. Emerging trends are reshaping production processes, design methodologies, and the overall customer experience. These innovations promise to enhance efficiency, reduce costs, and foster greater customization in the furniture industry.The adoption of Industry 4.0 technologies in smart furniture factories is not merely a shift, but a paradigm change.

It’s about creating interconnected systems that optimize every stage of the manufacturing process, from material sourcing to final delivery. This evolution requires a strategic approach to integrating these technologies seamlessly and effectively.

Emerging Trends in Smart Factory Technologies

Several emerging trends are shaping the future of smart furniture factories. These include the increasing use of artificial intelligence for predictive maintenance, the rise of augmented reality (AR) and virtual reality (VR) in design and training, and the expansion of the Internet of Things (IoT) for real-time data collection and analysis. These trends, in combination, are driving a shift towards more dynamic and adaptable production environments.

Innovative Applications of Smart Factory Technologies

Examples of innovative applications include the use of robotic arms for intricate assembly tasks, the deployment of 3D scanners for precise measurements, and the implementation of smart sensors to monitor the quality of raw materials. These applications are designed to improve efficiency, accuracy, and the overall quality of the final product.

The Role of 3D Printing and Additive Manufacturing

D printing and additive manufacturing are revolutionizing furniture design and production. The technology allows for the creation of complex, intricate designs that were previously impossible to manufacture using traditional methods. This enables greater customization options and potentially lower production costs for small-batch orders. The potential to create unique, personalized pieces is particularly compelling.

Artificial Intelligence’s Impact on Furniture Design and Production

Artificial intelligence is poised to transform furniture design and production by automating tasks such as material selection, design optimization, and even product customization. AI algorithms can analyze vast datasets of design trends, customer preferences, and material properties to generate innovative designs and recommend optimal manufacturing processes. This will allow for greater personalization and faster design iterations.

Future Integrations of Emerging Technologies

| Technology | Application in Smart Furniture Factories | Potential Impact |

|---|---|---|

| Artificial Intelligence (AI) | Predictive maintenance, automated quality control, personalized design recommendations | Reduced downtime, improved quality, enhanced customer experience |

| 3D Printing/Additive Manufacturing | Rapid prototyping, customized designs, on-demand production | Faster turnaround times, reduced material waste, enhanced design flexibility |

| Augmented Reality (AR) | Interactive design tools, real-time assembly guidance, remote technical support | Improved design visualization, enhanced training, reduced errors |

| Internet of Things (IoT) | Real-time monitoring of production processes, automated inventory management, optimized logistics | Enhanced efficiency, improved traceability, reduced costs |

| Robotic Automation | Automated assembly, material handling, quality control | Increased production speed, improved precision, reduced labor costs |

Case Studies and Examples: Smart Factories In Furniture Production: Embracing Industry 4.0 Technologies

Implementing smart factory technologies in furniture production is no longer a futuristic concept; numerous furniture manufacturers are successfully leveraging these advancements. Real-world examples demonstrate the tangible benefits and the crucial steps involved in the transition to a smarter factory. These case studies highlight not only successful implementations but also the challenges overcome, offering valuable insights for other companies considering adopting similar strategies.

Successful Implementations in Furniture Production

Numerous furniture companies have successfully integrated smart factory technologies. These implementations demonstrate the practical application of these technologies, showing how they can improve efficiency, reduce costs, and enhance product quality. Key characteristics of successful implementations include strong leadership support, a clear understanding of the desired outcomes, and a well-defined implementation plan.

Specific Challenges Overcome

Transitioning to a smart factory isn’t without hurdles. Companies often face challenges in data integration, cybersecurity, and employee training. One common hurdle is the need to integrate various systems and software platforms. Another significant challenge is ensuring the smooth transition for employees who may require retraining or adaptation to new processes. Addressing these challenges proactively is crucial for successful implementation.

Successful companies have overcome these hurdles by carefully planning the transition, investing in training programs, and developing robust cybersecurity protocols.

Outcomes Achieved by Implementations

Successful smart factory implementations have resulted in demonstrable improvements in various aspects of furniture production. Examples include increased productivity, reduced production time, and improved product quality. Reduced material waste, enhanced inventory management, and streamlined supply chains are also common outcomes. Quantifiable metrics, such as a 15% increase in production output or a 10% decrease in defect rates, are often observed.

Different Approaches to Implementation

Furniture companies have employed diverse approaches to implementing smart factory technologies. Some have focused on automating specific production stages, while others have opted for a more holistic approach, integrating smart technologies across the entire production process. Some have prioritized automation of repetitive tasks, while others have focused on enhancing data collection and analysis. Companies that implement a phased approach, starting with pilot projects, are often more successful in managing the complexity of the transition.

Key Lessons Learned from Case Studies

- Clear Vision and Leadership Support: Successful implementations are driven by strong leadership that champions the vision of a smart factory and actively supports the necessary changes. Leaders must articulate the benefits and provide resources for the transition.

- Phased Implementation: A phased approach, starting with pilot projects, allows for testing and refinement before widespread implementation. This approach helps manage complexity and ensures a smoother transition for employees.

- Data Integration and Analysis: Effective integration of data from various sources is crucial for gaining valuable insights into production processes. Robust data analysis provides actionable information to optimize efficiency and reduce costs.

- Employee Training and Empowerment: Successful implementation relies on effectively training employees to utilize new technologies and adapt to changing processes. Empowering employees to contribute ideas and feedback is also vital.

- Robust Cybersecurity Measures: Protecting sensitive data within the smart factory environment is paramount. Implementing strong cybersecurity protocols and regular security audits are essential.

Summary Table of Key Lessons

| Lesson | Description | Impact |

|---|---|---|

| Clear Vision & Leadership Support | Strong leadership champions the smart factory vision, supporting necessary changes. | Provides direction and resources for a successful transition. |

| Phased Implementation | Pilot projects test and refine technologies before full-scale implementation. | Manages complexity and facilitates a smoother transition. |

| Data Integration & Analysis | Effective integration of data from various sources for actionable insights. | Optimizes efficiency, reduces costs, and improves decision-making. |

| Employee Training & Empowerment | Training employees to utilize new technologies and adapt to processes. | Ensures a smooth transition and leverages employee expertise. |

| Robust Cybersecurity Measures | Protecting sensitive data within the smart factory environment. | Safeguards data integrity and maintains operational security. |

Conclusive Thoughts

In conclusion, Smart Factories in Furniture Production: Embracing Industry 4.0 Technologies represents a significant paradigm shift. By embracing these innovative technologies, furniture manufacturers can gain a competitive edge through enhanced productivity, reduced operational costs, and improved product quality. While challenges remain, the potential benefits are substantial. The future of furniture manufacturing hinges on the successful implementation of these smart factory solutions.

FAQ Insights

What are the specific benefits of using IoT in furniture production?

IoT enables real-time monitoring of equipment, allowing for proactive maintenance and reducing downtime. It also provides insights into production processes, facilitating optimized workflows and improved efficiency.

How does AI impact furniture design?

AI can automate the design process, generating various design options based on user preferences and specifications. This accelerates the design phase and enables more personalized and customized furniture.

What are some common challenges in implementing smart factories in furniture production?

Implementing smart factories requires significant upfront investment in new technologies and training for staff. Integrating different systems can also be complex and requires careful planning.

How can predictive maintenance reduce downtime in furniture factories?

Predictive maintenance utilizes data analysis to anticipate equipment failures, allowing for preventative measures to be taken before breakdowns occur. This minimizes costly downtime and ensures continuous production.