Modular Designs Enhance Manufacturing Efficiency, revolutionizing how products are made. This approach breaks down complex designs into smaller, independent modules, offering significant advantages in flexibility, scalability, and ultimately, efficiency. From streamlining production processes to improving inventory management and supporting rapid prototyping, modularity transforms the entire manufacturing landscape. This exploration dives deep into the principles, benefits, and practical applications of modular design.

The inherent flexibility of modular designs allows for easy adaptation to changing market demands and technological advancements. This adaptability is crucial in today’s dynamic environment. We’ll examine how modularity empowers companies to optimize their operations, reduce costs, and increase their overall competitiveness in the global market.

Introduction to Modular Design

Modular design in manufacturing involves breaking down a product into independent, self-contained modules. These modules can be designed, manufactured, and tested separately, then integrated to form the complete product. This approach offers significant advantages in terms of flexibility, scalability, and cost-effectiveness. The key is the standardized and interchangeable nature of these modules, enabling quick adaptation to changing demands and efficient resource allocation.

Definition of Modular Design

Modular design, in the context of manufacturing, is a design philosophy where a product is conceived and built as a collection of independent, interchangeable modules. These modules are designed to perform specific functions and can be combined in various configurations to create different product variations. This approach contrasts with traditional, monolithic designs where every component is integral to the whole.

Key Principles and Characteristics

Modular designs are characterized by:

- Standardization: Common interfaces and specifications across modules facilitate interchangeability and reduce design complexity.

- Interchangeability: Modules can be swapped or combined to create different product configurations without significant modification.

- Independent Development: Modules can be designed, manufactured, and tested independently, accelerating the development process and enabling parallel workflows.

- Scalability: The addition or removal of modules allows for easy expansion or contraction of product capabilities.

- Maintainability: Independent modules make maintenance and repair simpler, as only the affected module needs to be replaced, not the entire system.

Examples of Modular Design

Modular design is widely employed in various industries. In the automotive industry, engine modules, transmission modules, and chassis modules are common examples. In the electronics industry, circuit boards and component modules are frequently used, enabling flexible customization of products like computers and smartphones.

Advantages of Modular Design

The key benefits of modular design are its flexibility and scalability. This approach enables manufacturers to quickly adapt to changing market demands by modifying the combination of modules rather than redesigning the entire product. Scalability is achieved by simply adding or removing modules, enabling manufacturers to expand product offerings or adapt to increased demand.

Table: Modular Design Components

| Component | Module | Function | Benefits of Modularity |

|---|---|---|---|

| Engine | Powertrain Module | Provides power to the vehicle | Allows for different engine types to be used in different configurations. Faster development of new vehicles with new engine types. |

| Transmission | Powertrain Module | Transfers power from the engine to the wheels | Different transmission types can be used in different configurations. |

| Chassis | Body Module | Provides structural support and mounting points for components. | Different chassis types can be used in different configurations. Allows for customization and specific features for different markets. |

| Circuit Board | Electronics Module | Handles electrical signals and processing. | Facilitates upgrades and repairs, and different functionalities by using different circuit boards. |

| Processor | Electronics Module | Executes instructions. | Allows different processors for different needs and performance. |

Enhanced Manufacturing Efficiency Through Modularity

Modular designs offer a significant advantage in streamlining manufacturing processes, reducing lead times, and boosting production throughput. This approach, by breaking down complex products into independent, interchangeable modules, enables greater flexibility, adaptability, and efficiency across the entire production lifecycle. This approach proves particularly valuable in industries requiring rapid response to market demands and continuous product innovation.Modular designs facilitate a more efficient production process through standardized components and pre-assembled modules.

This simplification allows for faster assembly and reduced errors, leading to increased production throughput and shorter lead times. The inherent predictability and efficiency in manufacturing processes are key drivers of increased productivity.

Streamlined Manufacturing Processes

Modular designs drastically simplify manufacturing processes by reducing the number of individual parts and assembly steps. This reduction leads to less complexity in manufacturing processes, making the assembly process more manageable and predictable. Standardized interfaces between modules allow for automated assembly, further enhancing efficiency and minimizing human error. The streamlined nature of modular designs facilitates the introduction of new technologies and techniques, enabling improvements in production methods.

Reduced Lead Times and Improved Production Throughput

Modular designs significantly reduce lead times by enabling the pre-assembly of modules. Pre-fabricated modules can be assembled quickly, reducing the overall time needed to complete a product. This reduced assembly time directly impacts production throughput, enabling manufacturers to produce more units in a given timeframe. Companies like Boeing and Airbus, known for complex aircraft assembly, have leveraged modularity to significantly shorten production cycles and enhance overall manufacturing efficiency.

Impact on Inventory Management and Material Handling, Modular Designs Enhance Manufacturing Efficiency

Modular designs improve inventory management by allowing for the separate storage and tracking of individual modules. This modular approach allows for just-in-time inventory management strategies, optimizing resource utilization and reducing warehousing costs. The reduced complexity of components also simplifies material handling, enabling more efficient movement of modules through the production process. Minimizing inventory levels can significantly reduce warehousing costs and improve cash flow.

Support for Customization and Rapid Prototyping

Modular designs inherently support customization. By using interchangeable modules, manufacturers can easily configure products to meet specific customer needs. This adaptability enables rapid prototyping by quickly assembling different module combinations. This flexibility enables companies to respond to changing market demands and introduce new products more quickly, thus staying ahead of competitors.

Comparison of Traditional and Modular Manufacturing

| Feature | Traditional Manufacturing | Modular Manufacturing | Efficiency Gain |

|---|---|---|---|

| Component Complexity | High | Low | Reduced assembly time, lower errors |

| Assembly Time | High | Low | Faster production cycles, increased throughput |

| Inventory Management | Complex | Simplified | Reduced inventory costs, optimized resource use |

| Customization | Limited | High | Rapid response to market demands, improved product offerings |

| Lead Time | High | Low | Faster product delivery to customers |

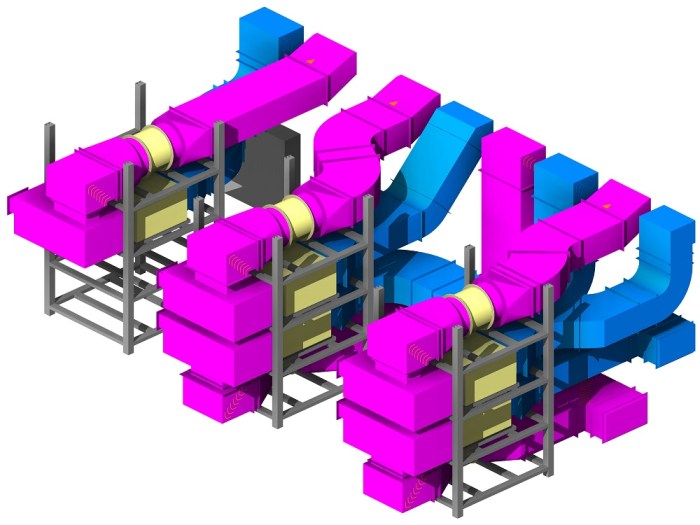

Components and Sub-Assemblies

Modular designs rely heavily on the use of standardized components and sub-assemblies. This approach allows for greater flexibility, reduced manufacturing costs, and enhanced interchangeability of parts. A key benefit of modularity is the ability to quickly adapt designs to changing requirements by swapping out modules rather than redesigning the entire system.Modular design principles require a deep understanding of the interrelationships between components and sub-assemblies.

This involves carefully considering the interfaces, connections, and compatibility requirements to ensure seamless integration.

Types of Components and Sub-Assemblies

Modular designs utilize a wide range of components and sub-assemblies. These range from simple fasteners and connectors to complex mechanical assemblies. The selection and design of these components are crucial to achieving the desired functionality, efficiency, and cost-effectiveness of the final product.

Interoperability and Compatibility Requirements

Effective modular design demands precise interoperability and compatibility between modules. This includes ensuring that the interfaces and connections between modules are standardized and precisely defined. Compatibility issues are a significant source of delays and complications in modular manufacturing. Standardized designs reduce the potential for these issues.

Standardized Interfaces and Connections

Standardized interfaces and connections are fundamental to modular systems. These standardized interfaces facilitate the easy connection and disconnection of modules, as well as their interchangeability. Well-defined specifications for these interfaces minimize the potential for mismatches or errors during assembly. A standardized interface typically includes a precise dimensioning and material specifications for the connector components. For example, a standard screw thread type, size, and material will allow for easy connection and disconnection of components.

Support of Standardized Components

Modular design intrinsically supports the use of standardized components. By defining clear specifications for each module, manufacturers can leverage readily available and cost-effective standardized components. This approach reduces development time and cost, and also increases the availability of replacement parts. Standardization also promotes interoperability across different modules and systems.

Module Types and Functions

The table below Artikels different types of modules and their specific functions. This demonstrates the wide range of applications for modular designs.

| Module Type | Specific Function |

|---|---|

| Mechanical Module | Provides structural support, movement, and power transmission. |

| Electrical Module | Handles electrical power distribution, control, and signal processing. |

| Control Module | Performs automated control functions, data processing, and decision-making. |

| Sensor Module | Measures physical parameters like temperature, pressure, and position. |

| Software Module | Provides specific software functions, such as data analysis, user interfaces, and communication protocols. |

Design for Manufacturing and Assembly (DFMA) in Modular Systems

Modular design, when integrated with Design for Manufacturing and Assembly (DFMA) principles, significantly enhances manufacturing efficiency. DFMA, in essence, optimizes the design for ease of production and assembly, thereby reducing costs and lead times. This approach is particularly valuable in modular systems, where components are designed to be interchangeable and easily assembled into various configurations.Applying DFMA principles to modular systems necessitates a proactive approach to manufacturability from the outset of the design process.

This proactive stance ensures that modules are not only functional but also readily producible and assemblable. This is pivotal for maintaining the advantages of modularity while avoiding the complexities of non-manufacturable components.

Application of DFMA Principles to Modular Design

DFMA principles are foundational to the success of modular design. By incorporating these principles, manufacturers can ensure that modules are designed with manufacturability in mind, leading to reduced costs and faster production times. This involves meticulously considering factors such as material selection, component geometry, and tooling requirements. By considering these factors, the final product becomes easier to manufacture and assemble, leading to significant cost savings.

Importance of Manufacturability in Module Design

Manufacturability is paramount in the design of modules. This means that modules must be designed with the manufacturing processes in mind, ensuring they can be produced efficiently and cost-effectively. Consideration should be given to material properties, tooling requirements, and potential process bottlenecks. For example, a module with complex geometries might require specialized tooling, increasing manufacturing costs. Conversely, a module with simple, standard shapes is more likely to be produced using existing equipment, reducing manufacturing costs.

A modular design that prioritizes manufacturability allows for the use of readily available materials and processes, further enhancing efficiency.

Ergonomics and Accessibility in Modular Component Design

Ergonomics and accessibility are critical factors in the design of modular components. Designing for ease of handling and assembly by the manufacturing personnel is crucial. This encompasses the size, shape, weight, and placement of components. Modules that are lightweight, easily grasped, and have clear assembly instructions significantly improve assembly efficiency and worker safety. Moreover, accessible component features reduce the risk of errors and injuries during assembly.

By incorporating ergonomic principles, manufacturers can optimize the working environment and ensure that assembly tasks are safe and comfortable.

Strategies for Designing for Ease of Assembly and Disassembly

Strategies for designing for ease of assembly and disassembly include standardization of interfaces, intuitive component features, and clear assembly instructions. Standardization ensures interchangeability and simplifies assembly procedures. Intuitive component features, such as specific grooves or tabs, guide assembly, reducing errors and speeding up the process. Comprehensive and well-illustrated assembly instructions, accessible to all personnel, minimize assembly time and errors.

Modules should also be designed for easy disassembly, facilitating maintenance and future modifications.

Comparison of DFMA Principles in Traditional and Modular Manufacturing

| Feature | Traditional Manufacturing | Modular Manufacturing |

|---|---|---|

| Component Design | Focus on individual part design; potentially less standardized | Focus on standardized modules; designed for interchangeability and modularity |

| Manufacturing Process | Often tailored to individual parts; potentially more complex | Leverages standardized processes for modules; more efficient |

| Assembly | Complex assembly procedures; potentially more prone to errors | Modular assembly procedures; easier to manage and standardize |

| Maintenance | Complex maintenance procedures | Simplified maintenance; easier to replace modules |

| Flexibility | Limited flexibility in adapting to changes | High flexibility in adapting to changes and modifications |

Supply Chain Management and Modularity

Modular design significantly alters how products are manufactured and delivered to the customer, impacting the entire supply chain. This approach, by breaking down complex products into smaller, independent modules, introduces new opportunities for optimizing various supply chain processes. The benefits extend from enhanced resilience to reduced risks and improved inventory management, ultimately leading to a more efficient and adaptable supply chain.

Impact on the Supply Chain

Modular design fundamentally alters the supply chain landscape. Instead of a single, complex product with numerous interconnected parts, modularity creates a network of smaller, independent components. This enables parallel production, allowing multiple suppliers to work simultaneously on different modules. It also opens the possibility of using a geographically dispersed supply chain, as individual modules can be sourced from various locations.

This diversification of sourcing reduces dependency on a single supplier and strengthens the supply chain’s overall resilience.

Benefits for Supply Chain Resilience and Flexibility

Modularity enhances supply chain resilience by minimizing the impact of disruptions. If a specific supplier faces issues, the impact on the entire product is contained, as only the affected module is affected. The decoupling of components allows for quicker response times to disruptions and facilitates the rapid substitution of affected modules. This flexibility is critical in today’s volatile market, where supply chain disruptions are increasingly common.

For instance, a manufacturer producing a modular aircraft can easily switch suppliers for a specific engine module without halting production of the entire aircraft.

Reducing Supply Chain Risks and Dependencies

By breaking down products into independent modules, modularity reduces supply chain risks by mitigating the impact of individual supplier failures. This approach distributes risk across a larger network of suppliers, lowering the chance of a single disruption affecting the entire supply chain. The increased diversification of suppliers also lessens the dependence on any single entity, making the supply chain more robust and adaptable to changing market conditions.

For example, a modular furniture company can easily substitute a specific component if a supplier encounters issues, thereby avoiding production halts.

Efficient Inventory Management in the Supply Chain

Modularity facilitates efficient inventory management. Separate inventory management for individual modules allows for greater control and precision in tracking and forecasting demand. This granular approach reduces excess inventory and optimizes storage space. The ability to manufacture modules in smaller batches or on-demand further improves inventory control and reduces storage costs. This approach aligns production with actual demand, reducing waste and optimizing resource allocation.

For example, a company producing modular building components can adjust production based on the current demand for particular modules, avoiding the need to hold large inventories of unsold components.

Table: Enhancing Supply Chain Resilience with Modular Designs

| Aspect | How Modular Design Improves |

|---|---|

| Supplier Diversification | Reduces dependency on single suppliers, creating redundancy and resilience in case of supplier issues. |

| Risk Mitigation | Limits the impact of disruptions by isolating failures within specific modules, preventing cascading effects. |

| Inventory Control | Enables precise tracking and forecasting of demand for individual modules, minimizing excess inventory and improving efficiency. |

| Response Time | Facilitates quicker response to disruptions by allowing for the rapid substitution of modules without impacting the entire product. |

| Adaptability | Enables the supply chain to adjust to changing market conditions, new technologies, and emerging trends more easily. |

Cost Analysis and Return on Investment (ROI): Modular Designs Enhance Manufacturing Efficiency

Source: com.au

Modular design offers significant potential for enhanced manufacturing efficiency and cost reduction. Understanding the factors influencing implementation costs, conducting a comparative analysis with traditional methods, and evaluating the return on investment (ROI) is crucial for successful adoption. A thorough cost analysis provides a clear picture of the financial benefits, enabling informed decisions about integrating modularity into manufacturing processes.

Factors Influencing Implementation Costs

Several factors contribute to the total cost of implementing modular designs. These include the initial investment in design tools and software, the cost of training personnel to utilize the modular system, the time required for design and implementation, and potential costs associated with integrating existing systems with the modular framework. The complexity of the modular system, the level of customization required, and the extent of supplier involvement in the design process can also impact the overall cost.

Cost Analysis of Modular Manufacturing vs. Traditional Methods

A comprehensive cost analysis compares the total cost of ownership (TCO) for modular and traditional manufacturing approaches. This includes direct costs, such as material costs, labor costs, and tooling costs, as well as indirect costs, such as overhead expenses and potential downtime. Analyzing the life-cycle costs of each approach is essential. Modular design, while potentially higher upfront, often demonstrates lower long-term costs due to improved efficiency, reduced waste, and increased flexibility.

Return on Investment (ROI) of Modular Designs

The ROI of modular designs is evaluated by comparing the projected savings against the initial investment. Factors such as reduced material waste, decreased manufacturing time, and improved product quality contribute to increased profitability. Modular designs facilitate the production of diverse product variants, thereby expanding market reach and potential revenue streams. For example, a company transitioning to modular design for car assembly could see a reduction in manufacturing time per unit, potentially leading to higher production volume and increased profits.

Factors Contributing to Potential Cost Savings

Modular designs lead to significant cost savings through various mechanisms. Standardized components reduce design and production time, leading to lower overall manufacturing costs. The reuse of components across multiple products reduces material waste and minimizes the need for specialized tooling. Improved quality control through modular design reduces the rate of defects and rework, resulting in decreased manufacturing costs.

A reduction in inventory costs due to optimized supply chain management is another key contributor.

Comparison of Total Cost of Ownership

| Cost Category | Modular Manufacturing | Traditional Manufacturing |

|---|---|---|

| Initial Design and Implementation Costs | Potentially higher | Lower |

| Manufacturing Costs (per unit) | Potentially lower in the long term | Potentially higher in the long term |

| Material Costs | Potentially lower due to optimized material usage | Potentially higher due to waste |

| Labor Costs | Potentially lower due to streamlined processes | Potentially higher due to more complex tasks |

| Inventory Costs | Potentially lower due to reduced component inventory | Potentially higher due to higher component inventory |

| Total Cost of Ownership (over product lifecycle) | Potentially lower | Potentially higher |

Note: The table above provides a general comparison. Actual costs will vary based on the specific product, manufacturing process, and scale of implementation.

Case Studies of Modular Designs in Different Industries

Modular design principles, when effectively implemented, can significantly enhance manufacturing efficiency and product development processes across various industries. This approach fosters flexibility, scalability, and cost-effectiveness, ultimately impacting the bottom line. Successful case studies demonstrate the tangible benefits of modularity, offering valuable insights for companies considering adopting this methodology.Modular design strategies have proven effective in reducing production time and improving quality.

By breaking down complex products into standardized, interchangeable modules, companies can streamline assembly processes and minimize errors. This approach also allows for greater customization and adaptation to evolving market demands.

Successful Implementations in the Automotive Industry

Modular design has revolutionized the automotive industry, enabling manufacturers to create a wide range of vehicle models from a common set of components. This approach allows for faster production cycles and reduced costs. For example, several manufacturers use modular platforms for different vehicle segments. This allows for the creation of various car models (sedans, SUVs, trucks) using a common platform.

By utilizing a common platform, manufacturers can share components across multiple vehicle types, significantly reducing development and manufacturing costs. This standardization also facilitates quicker adaptation to market demands, allowing for rapid introduction of new models and features.

Modular Design in the Construction Industry

Prefabricated building systems, leveraging modular design principles, are gaining traction in the construction sector. Pre-assembled modules, which incorporate plumbing, electrical, and structural elements, can be transported to the construction site and assembled rapidly. This approach drastically reduces on-site construction time, minimizes labor costs, and enhances project predictability. Modular construction has also been shown to minimize construction waste.

By streamlining the building process, modular construction can enhance overall efficiency and reduce the environmental impact of building projects. For instance, the use of standardized modules in residential constructions can significantly reduce on-site labor requirements and lead to faster project completion.

Modular Design in the Electronics Industry

Modular design principles have also been applied effectively in the electronics industry, where standardized components and sub-assemblies allow for faster production cycles. This approach facilitates the creation of different product configurations with the same core components. A prominent example is the use of modular components in data centers, enabling rapid expansion and customization to specific needs. By using standardized modules, manufacturers can streamline the assembly process and reduce the time required to create new product variants.

For example, a company manufacturing computer servers can utilize standardized modules for power supplies, cooling systems, and networking equipment, which can be easily integrated into different server configurations.

Advantages and Disadvantages of Modularity

- Advantages: Modular designs generally allow for quicker development cycles, increased flexibility in product customization, reduced manufacturing costs, and easier maintenance and repair. This enhanced adaptability and reduced complexity contribute to improved product quality and customer satisfaction.

- Disadvantages: Designing and integrating modules can be complex. Potential challenges include the need for specialized tooling, integration issues between modules, and potential conflicts with existing processes and equipment.

Summary of Case Studies

| Industry | Benefits | Challenges |

|---|---|---|

| Automotive | Reduced development costs, faster production cycles, increased flexibility | Integration complexities, potential for design conflicts |

| Construction | Faster construction times, reduced labor costs, minimized waste | Logistics and transportation complexities, regulatory approvals |

| Electronics | Streamlined assembly, rapid product customization, reduced production time | Component integration, testing complexity |

Future Trends and Advancements in Modular Design

Modular design is rapidly evolving, driven by advancements in technology and the increasing need for adaptable and efficient manufacturing processes. This evolution promises to reshape manufacturing landscapes, fostering greater flexibility and cost-effectiveness across diverse industries. The future of modular design is characterized by the integration of emerging technologies, leading to more sophisticated and optimized solutions.

Emerging Technologies Influencing Modular Design

The adoption of digital twin technologies is a significant trend. Digital twins provide virtual representations of physical products and systems, enabling engineers to simulate and optimize modular designs before physical prototyping. This process minimizes design iterations and accelerates the development cycle. 3D printing and additive manufacturing are also transforming modular design by enabling the creation of complex, intricate components with tailored geometries.

Furthermore, the use of Artificial Intelligence (AI) and Machine Learning (ML) algorithms is enabling predictive maintenance and optimization of modular systems throughout their lifecycle.

Future of Modular Manufacturing

Modular manufacturing is expected to become more interconnected and data-driven. This interconnectedness will allow for real-time monitoring and control of manufacturing processes, facilitating better resource allocation and optimized production schedules. The integration of Industry 4.0 technologies, such as the Internet of Things (IoT), will facilitate seamless data exchange and communication between different components of the modular system, enabling better coordination and control across the entire supply chain.

Role of Automation and Robotics in Supporting Modular Designs

Automation and robotics are crucial components in supporting modular designs. Automated assembly lines can handle the repetitive tasks associated with modular systems, enhancing efficiency and precision. Robotic arms and systems can be programmed to manipulate and assemble different modules, enabling flexible and scalable manufacturing operations. This increased automation leads to reduced labor costs, higher production rates, and improved quality control.

Impact of Additive Manufacturing on Modular Design

Additive manufacturing (AM) is revolutionizing the way modular designs are conceptualized and realized. AM technologies allow for the creation of complex geometries and intricate shapes that were previously unattainable through traditional manufacturing methods. This opens doors for the development of highly customized and specialized modular components. Furthermore, AM enables on-demand production of individual modules, reducing inventory costs and lead times.

Summary of Future Trends in Modular Design

| Technology | Industry Applications |

|---|---|

| Digital Twins | Improved design optimization, predictive maintenance, reduced prototyping costs in automotive, aerospace, and construction. |

| 3D Printing/Additive Manufacturing | Customization of components, creation of complex geometries, reduced lead times in medical devices, consumer goods, and aerospace. |

| Artificial Intelligence (AI) and Machine Learning (ML) | Predictive maintenance, optimized production schedules, and improved resource allocation in manufacturing, logistics, and supply chains. |

| Automation and Robotics | Enhanced assembly precision, flexible manufacturing operations, and reduced labor costs in automotive, electronics, and consumer goods. |

| Internet of Things (IoT) | Real-time monitoring and control of manufacturing processes, improved supply chain management, and enhanced communication across different components in diverse industries. |

Concluding Remarks

Source: z-modular.com

In conclusion, Modular Designs Enhance Manufacturing Efficiency by offering a powerful paradigm shift in product design and manufacturing. We’ve seen how modularity streamlines processes, reduces lead times, and supports customization, all while enhancing supply chain resilience. This approach fosters a more adaptable and agile manufacturing ecosystem, ready to embrace the challenges and opportunities of the future.

Essential Questionnaire

What are the typical costs associated with implementing modular designs?

Implementing modular designs can involve upfront costs for redesigning components and establishing standardized interfaces. However, these costs are often offset by long-term benefits such as reduced production lead times, improved inventory management, and enhanced scalability.

How does modularity impact supply chain resilience?

Modularity allows for a more diversified supply chain, reducing reliance on single suppliers and mitigating risks associated with disruptions. The independent modules enable quicker responses to supply chain challenges and facilitate a more flexible and resilient system.

What are some examples of industries leveraging modular designs?

The automotive, electronics, and aerospace industries are just a few examples of sectors that have successfully implemented modular designs. These industries recognize the benefits of modularity in enhancing product customization, improving production efficiency, and supporting rapid prototyping.