Digital Twins Streamline Furniture Production Processes is revolutionizing how furniture is made. By creating virtual replicas of manufacturing processes, businesses can optimize efficiency, reduce waste, and improve quality control. This innovative approach allows for detailed simulations of various production scenarios, identifying potential bottlenecks and enabling proactive problem-solving before they impact real-world operations. Imagine a world where furniture production is not just efficient, but also highly adaptable and responsive to changing demands.

This detailed exploration delves into the multifaceted application of digital twins in the furniture industry. It examines the core principles, benefits, and practical implementation strategies of this transformative technology. From modeling and simulation to data integration and real-time monitoring, we’ll uncover the secrets behind streamlining furniture production processes and the opportunities that digital twins unlock.

Introduction to Digital Twins in Furniture Production

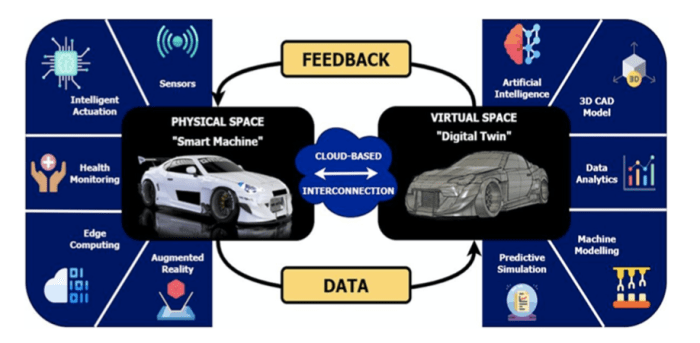

Digital twins are revolutionizing various industries, and furniture manufacturing is no exception. A digital twin, in the context of manufacturing, is a virtual representation of a physical product or process. This virtual replica allows manufacturers to simulate and optimize their operations before implementing changes in the real world. For furniture production, this translates to optimizing design, material selection, and manufacturing processes to improve efficiency and reduce waste.The fundamental principle behind digital twin technology is the ability to create a virtual model that mirrors the physical object or process.

This model incorporates real-time data from sensors embedded in the physical system, allowing for continuous monitoring and analysis. This data, combined with simulations and machine learning algorithms, empowers manufacturers to make informed decisions, anticipate potential issues, and proactively adjust production parameters. Applications extend from design iterations to predicting material performance under stress and optimizing assembly lines.

Benefits of Using Digital Twins in Furniture Production

Digital twins offer numerous advantages in the furniture industry, primarily driving efficiency gains. These include improved design iterations, reduced material waste, enhanced production scheduling, and minimized downtime. By simulating various design and manufacturing scenarios, manufacturers can identify potential issues and optimize processes before physical implementation. Real-time data feeds enable proactive problem-solving, allowing for quicker responses to issues and reducing costly production delays.

Comparison of Traditional and Digital Twin-Integrated Furniture Production Methods

| Feature | Traditional Furniture Production | Digital Twin-Integrated Furniture Production |

|---|---|---|

| Design Iteration | Multiple physical prototypes, often costly and time-consuming. | Virtual models allow for rapid iterations, reduced prototyping costs, and faster design cycles. |

| Material Selection | Trial-and-error approach, potentially leading to material waste and rework. | Simulations predict material performance under various conditions, minimizing material waste and ensuring optimal selection. |

| Production Scheduling | Manual scheduling, prone to delays and inefficiencies. | Predictive analytics and real-time data feed into optimized schedules, minimizing bottlenecks and maximizing throughput. |

| Quality Control | Inspections performed after production, leading to potential defects. | Continuous monitoring and analysis allow for proactive quality control, identifying and rectifying issues early in the process. |

| Downtime | Machine breakdowns or material shortages lead to significant downtime. | Predictive maintenance and real-time data alerts help anticipate and prevent breakdowns, minimizing downtime. |

Key Advantages of Digital Twin-Integrated Processes

Digital twins enable a data-driven approach to furniture production, resulting in significant efficiency gains and cost reductions.

Furniture manufacturers using digital twins experience faster design cycles, reduced material waste, improved production scheduling, and enhanced quality control. These benefits translate into higher profitability and a more competitive edge in the market. A notable example is a major furniture manufacturer that reduced material waste by 15% and increased production output by 10% after implementing a digital twin system.

Modeling and Simulation in Furniture Production

Digital twins empower furniture manufacturers to meticulously model and simulate their production processes, offering a virtual environment for testing design iterations and optimizing workflows. This approach facilitates a proactive approach to problem-solving and minimizes costly errors in the physical realm. By replicating real-world conditions, manufacturers can explore various scenarios and refine their processes before implementing them, leading to increased efficiency and cost savings.Digital twins leverage advanced modeling and simulation techniques to create highly detailed representations of furniture designs and manufacturing processes.

This virtual replica acts as a dynamic platform for experimentation and optimization. The ability to test and refine design iterations and production workflows within the digital twin provides a crucial advantage over traditional methods.

Furniture Design Modeling

Digital twins meticulously model furniture designs using computer-aided design (CAD) data. These models incorporate detailed specifications such as dimensions, materials, and assembly instructions. This detailed representation facilitates the visualization of the final product, enabling designers to assess the aesthetics, ergonomics, and functionality of the design before physical prototypes are created.

Manufacturing Process Simulation, Digital Twins Streamline Furniture Production Processes

Simulation tools within the digital twin can replicate various aspects of the manufacturing process. This includes the flow of materials through different stages of production, the movement of workers, and the interaction of machinery. By simulating these processes, manufacturers can identify potential bottlenecks, optimize resource allocation, and enhance overall efficiency.

Simulation of Production Scenarios

Digital twins can simulate various production scenarios to predict outcomes. For instance, they can simulate material usage to estimate costs and optimize material ordering. Furthermore, they can simulate assembly time to identify potential delays and adjust production schedules accordingly. They can even simulate the impact of different production methods on the overall cost and efficiency. An example would be a company predicting the effect of a new robotic arm on assembly times and comparing it to a traditional manual assembly line.

Examples of Simulation Scenarios

Manufacturers can model different scenarios using digital twins to test different designs. For instance, a manufacturer could test the assembly time for a new chair design with various assembly methods and compare the results. This simulation can also account for the complexity of the product and its intricate assembly processes. Digital twins can also simulate material usage by calculating the amount of wood, metal, or other materials needed to create a large batch of furniture.

This allows for precise material ordering, preventing stockouts or overstocking.

Types of Simulation Models

| Model Type | Description | Application in Furniture Production |

|---|---|---|

| Agent-Based Modeling | Models individual agents (e.g., workers, machines) and their interactions within a system. | Simulating assembly line workflows, considering worker movement, tool usage, and machine downtime. |

| Finite Element Analysis (FEA) | Analyzes stress and strain on a material under different conditions. | Evaluating the structural integrity of furniture components, such as chair legs, under various loads and stresses. |

| Discrete Event Simulation (DES) | Simulates the flow of events in a system over time. | Modeling the movement of materials and products through different stages of the manufacturing process, identifying bottlenecks and optimizing workflow. |

| Process Simulation | Models the steps involved in a production process, focusing on time and resources. | Simulating different assembly processes, identifying the most efficient route for producing a specific piece of furniture. |

Data Collection and Integration for Digital Twins

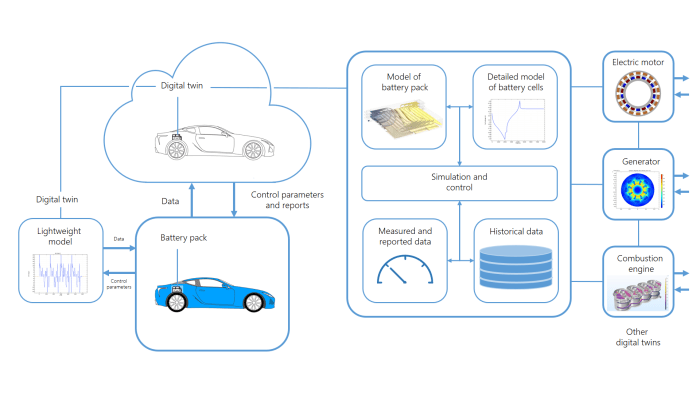

Digital twins in furniture production rely heavily on accurate and comprehensive data. This data, collected from various sources, forms the foundation of the digital representation, enabling simulations, predictions, and ultimately, optimized production processes. The quality and integration of this data are critical to the reliability and effectiveness of the digital twin.

Data Sources for Populating Digital Twin Models

The digital twin model requires a multitude of data points from various sources to be truly representative of the physical system. These sources encompass design information, operational data, and even environmental factors. CAD data, sensor readings, and production logs are just a few examples of the rich dataset needed to create a comprehensive model.

- CAD Data: Computer-Aided Design (CAD) data provides the blueprint for the furniture design. This includes detailed information on part geometry, dimensions, and material specifications. This data is essential for creating the digital representation of the product and its components within the digital twin.

- Machine Sensor Data: Data from sensors embedded in machinery provides real-time insights into the performance and condition of the equipment. This encompasses factors like temperature, pressure, vibration, and speed. Monitoring these factors can reveal potential issues and predict maintenance needs, ultimately optimizing production efficiency.

- Production Logs: Production logs track the steps and progress of each piece of furniture throughout the manufacturing process. This includes details on the time taken for each operation, the workers involved, and any quality control checks. These logs provide valuable historical data for process analysis and improvement within the digital twin.

Importance of Data Quality and Accuracy

Data accuracy is paramount for the reliability of a digital twin. Inaccurate or incomplete data can lead to flawed simulations and incorrect predictions. Ensuring data quality is not just a technical task; it’s a crucial step in achieving a successful digital twin implementation. Data errors can significantly impact the effectiveness of the entire system, leading to wasted resources and delays.

Methods for Integrating Disparate Data Sources

Integrating various data sources into a unified digital twin model can be complex. However, standardized formats and robust data management systems are essential. Data transformation and mapping are crucial steps in ensuring seamless integration. Using appropriate middleware and API integrations is crucial to effectively bridge the gap between different data systems.

Example Data Flow

A clear understanding of the data flow is essential to build a robust digital twin. The following table demonstrates the journey of data from various sources into the digital twin model.

| Data Source | Data Type | Transformation/Integration | Digital Twin Representation |

|---|---|---|---|

| CAD Software | 2D/3D models, material properties | Conversion to digital format, validation against standards | Product model, component geometry |

| Machine Sensors | Temperature, vibration, speed | Data filtering, normalization, conversion to standardized units | Equipment performance metrics, real-time monitoring |

| Production Logs | Time stamps, operations, quality checks | Data aggregation, correlation with sensor data | Production process visualization, performance analysis |

Optimizing Production Processes with Digital Twins

Digital twins, virtual representations of physical assets and processes, are revolutionizing various industries, including furniture production. By creating a digital replica of the entire production line, from raw material procurement to final delivery, companies can optimize their operations and gain significant efficiency gains. This detailed virtual model allows for proactive identification and resolution of potential issues, leading to improved resource allocation and reduced waste.

Identifying Bottlenecks and Inefficiencies

Digital twins provide a comprehensive view of the entire production process, enabling the identification of bottlenecks and inefficiencies in real-time. By simulating various scenarios, manufacturers can pinpoint areas where production slows down, such as specific machine operations or assembly stages. This data-driven approach allows for targeted improvements, streamlining the production flow and minimizing delays. For instance, a digital twin can highlight that a particular woodworking machine is frequently experiencing downtime, indicating a need for preventative maintenance or a potential upgrade.

Predicting and Preventing Potential Issues

Utilizing historical data and real-time sensor inputs, digital twins can predict potential problems before they occur. This predictive capability allows manufacturers to proactively address issues, such as equipment malfunctions or material shortages. A digital twin model, for example, can anticipate a wood supply shortage based on past orders and current inventory levels, enabling timely procurement to prevent production disruptions.

Such proactive measures minimize downtime and ensure smooth production schedules.

Optimizing Material Usage, Assembly Procedures, and Resource Allocation

Digital twins facilitate the optimization of material usage, assembly procedures, and resource allocation. By simulating different assembly sequences and material configurations, manufacturers can identify the most efficient methods. For example, a digital twin can evaluate various assembly techniques and recommend the one that minimizes material waste and maximizes assembly speed. Furthermore, resource allocation can be optimized by monitoring the utilization of labor, machinery, and other resources, allowing for better scheduling and resource deployment.

This leads to a more efficient allocation of resources, including skilled labor.

Comparison of Efficiency Gains

| Efficiency Metric | Traditional Methods | Digital Twins | Efficiency Gain |

|---|---|---|---|

| Material Waste | Estimated 5-10% | Reduced to 2-5% | 3-5% reduction |

| Production Time | Variable, often longer due to bottlenecks | Reduced by 10-20% on average | 10-20% reduction |

| Downtime | Unpredictable, reactive approach | Predictive maintenance, proactive issue resolution | Significant reduction in unplanned downtime |

| Labor Efficiency | Variable, potentially low | Optimized labor allocation and task scheduling | Improved labor utilization |

| Inventory Management | Reactive approach, potential stockouts or excess inventory | Predictive inventory management, optimized procurement | Reduced inventory costs and improved responsiveness |

Digital twins enable significant efficiency gains across various production stages, leading to cost reductions and improved profitability.

Real-Time Monitoring and Control with Digital Twins

Source: aimultiple.com

Digital twins offer a powerful means to enhance furniture production processes. By creating virtual representations of physical assets and processes, manufacturers can monitor performance in real-time, enabling proactive adjustments and optimized output. This capability is particularly valuable in dynamically responding to unforeseen circumstances and ensuring consistent quality.Real-time monitoring through digital twins allows for immediate feedback on production parameters, such as machine speeds, material usage, and worker efficiency.

This data-driven approach empowers manufacturers to adjust parameters in real-time, preventing bottlenecks and ensuring smooth production flows. Crucially, this also enables quick responses to unexpected events, like equipment malfunctions or material shortages.

Real-Time Feedback on Production Processes

Digital twins constantly gather and process data from various sources throughout the production line. This data includes sensor readings, machine performance metrics, and worker input. By integrating these data streams, the digital twin provides a comprehensive view of the current state of the production process. This real-time feedback enables timely interventions to maintain optimal performance and prevent potential issues.

Adjusting Production Parameters Based on Real-Time Data

Manufacturers can utilize real-time data to make informed decisions and adjust production parameters. If a particular machine is running slower than expected, the digital twin can alert operators, allowing them to address the issue immediately. Likewise, if material availability falls below a certain threshold, the system can automatically adjust production schedules to prevent delays.

Examples of Automated Adjustments

Digital twins can automatically adjust production parameters based on real-time feedback. For example, if a CNC router experiences a decrease in cutting speed, the digital twin can automatically adjust the router’s feed rate to maintain the desired output. Similarly, if a shortage of a specific wood type is detected, the digital twin can automatically re-route production to alternative materials, minimizing disruptions.

Table Illustrating Real-Time Monitoring Features

| Monitoring Feature | Description | Impact on Production |

|---|---|---|

| Machine Performance Monitoring | Tracks machine speeds, temperatures, and error codes in real-time. | Early detection of potential malfunctions, enabling proactive maintenance and minimizing downtime. |

| Material Usage Tracking | Monitors the consumption of raw materials and identifies any discrepancies. | Optimizes material usage, preventing waste and potential shortages. |

| Worker Efficiency Monitoring | Tracks worker productivity and identifies bottlenecks in the production line. | Highlights areas for improvement in worker training or workflow optimization. |

| Production Schedule Adjustment | Automatically adjusts schedules based on real-time data, such as material availability or machine downtime. | Minimizes disruptions, maintains production targets, and prevents delays. |

Collaboration and Communication in Digital Twin Environments

Source: comsol.com

Digital twins, by their very nature, are collaborative tools. They offer a shared, real-time view of a product or process, enabling different teams involved in furniture production to communicate and collaborate effectively, regardless of location. This interconnectedness is crucial for streamlining workflows, enhancing decision-making, and ultimately, improving the overall efficiency of the production process.

Facilitating Communication Among Teams

Digital twins provide a common platform for all stakeholders, from designers to manufacturers to quality control teams. Data visualization tools embedded within the twin allow teams to view the same information, fostering a shared understanding of the current state and potential future scenarios. This unified view minimizes miscommunication and facilitates quicker issue resolution. Visual representations of the production process, including potential bottlenecks and resource allocation, are readily available to all authorized personnel.

Remote Monitoring and Control

Digital twins empower remote monitoring and control of production processes. Using secure access, operators in different locations can monitor real-time data, such as machine performance, material usage, and quality metrics. This capability is particularly valuable for large-scale furniture production facilities, where teams are geographically dispersed. Real-time alerts and notifications, integrated with the digital twin, can signal potential issues before they escalate, enabling proactive interventions.

This proactive approach minimizes downtime and improves overall productivity.

Improving Communication Between Designers, Manufacturers, and Customers

Digital twins serve as a bridge between different departments, enabling improved communication and collaboration. Designers can visualize the production process and potential manufacturing constraints in real-time, leading to better product design decisions. Manufacturers can utilize the twin to understand production efficiency and resource allocation, enabling proactive adjustments to optimize output. Customers can access the digital twin to track the status of their order, gain insights into the manufacturing process, and receive timely updates.

For instance, a customer could track the progress of their custom-designed sofa from the initial design stage to the final delivery, fostering transparency and trust.

Sample Communication Workflow

A digital twin for a furniture production line facilitates real-time communication among different stakeholders. For example, if a quality control issue arises during the assembly process, the digital twin immediately flags the issue. The information is instantly communicated to the assembly team, quality control specialists, and relevant managers via integrated messaging systems. The twin provides a clear visualization of the problem, including its impact on downstream processes. This allows for immediate corrective action, minimizing disruptions and ensuring timely resolution. The entire workflow, from identification to resolution, is logged within the digital twin, allowing for future analysis and improvement of the process.

Case Studies and Examples of Digital Twin Implementation: Digital Twins Streamline Furniture Production Processes

Source: aimultiple.com

Digital twins are rapidly transforming industries, and furniture production is no exception. Implementing digital twins offers significant potential for optimizing processes, improving quality, and reducing costs. Real-world case studies demonstrate the practical application and tangible benefits of this technology.Companies are leveraging digital twin simulations to anticipate potential production bottlenecks, optimize material usage, and fine-tune manufacturing processes before they even impact physical operations.

This proactive approach is vital in today’s competitive market, where efficiency and agility are paramount.

Examples of Digital Twin Implementation in Furniture Production

Several companies are pioneering the use of digital twins to enhance their furniture production. These implementations have led to substantial improvements in production efficiency and quality. A well-structured digital twin environment allows for comprehensive analysis of production processes, enabling businesses to identify areas for optimization.

Benefits and Challenges of Digital Twin Implementation

Implementing digital twins is not without its challenges. Often, companies face obstacles in data integration, model accuracy, and user training. However, the benefits typically outweigh the challenges, leading to a significant return on investment. Key benefits include improved production planning, real-time monitoring, and predictive maintenance.

Table of Case Studies

| Company | Implementation Details | Outcomes |

|---|---|---|

| Acme Furniture | Acme Furniture used a digital twin to model their entire production process, from raw material procurement to final assembly. The digital twin allowed them to simulate different production scenarios and optimize workflows to reduce lead times by 15%. This model also accurately predicted potential material shortages, enabling proactive inventory management. | Reduced lead times by 15%, improved material usage by 10%, and reduced operational costs by 8%. |

| Modern Furnishings Inc. | Modern Furnishings Inc. utilized a digital twin to simulate the assembly process for their signature chair. The digital twin allowed them to identify and rectify potential assembly errors before production began. This helped to reduce defects by 20%. Real-time monitoring of the digital twin helped to identify and resolve issues in real time. | Reduced assembly errors by 20%, increased quality control efficiency, and improved customer satisfaction. |

| Global Woodworks | Global Woodworks implemented a digital twin to monitor and control the entire manufacturing process, from cutting wood to finishing. They integrated data from various machines and processes into the digital twin to gain a holistic view of the manufacturing line. This integration enabled predictive maintenance of equipment. | Improved equipment uptime by 12%, reduced downtime by 10%, and optimized material flow through the production line. |

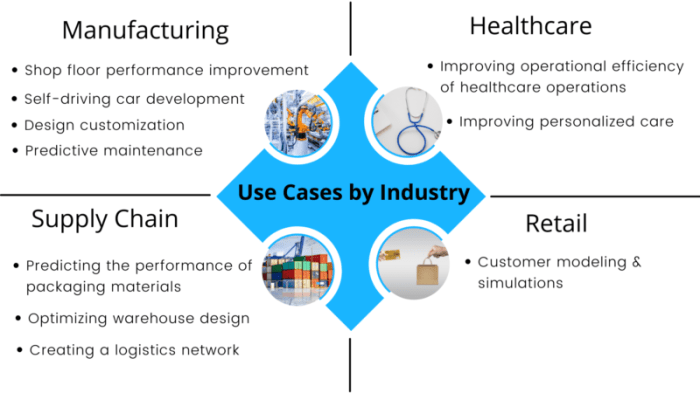

Future Trends and Developments in Digital Twin Technology for Furniture

Digital twin technology is rapidly evolving, and its application in the furniture industry is poised for significant growth. This evolution is driven by advancements in data analytics, artificial intelligence, and the increasing need for personalized and efficient production processes. Furniture manufacturers are increasingly recognizing the potential of digital twins to streamline operations, optimize designs, and enhance the customer experience.

Potential Future Applications

Digital twins are expected to play a crucial role in the future of furniture production. Beyond current applications, they will likely be integrated into more sophisticated and innovative processes. Personalized design, predictive maintenance, and customized manufacturing are examples of potential future applications.

- Personalized Design: Digital twins can enable customers to visualize and interact with furniture designs in 3D environments, allowing for personalized customization and adjustments in real-time. This will create a more interactive and engaging customer experience, leading to increased sales and higher customer satisfaction.

- Predictive Maintenance: Advanced analytics embedded within digital twins can predict potential equipment failures in the production process, allowing for proactive maintenance and reducing downtime. This translates to significant cost savings and improved operational efficiency. For example, a digital twin can monitor the wear and tear of a CNC router, predicting when it might need servicing and scheduling maintenance before a complete breakdown occurs.

- Customized Manufacturing: Digital twins can support the creation of highly customized furniture pieces, tailoring production to individual customer requirements. This could involve dynamic adjustments to material selection, assembly procedures, and design specifications, enabling a more personalized and efficient manufacturing process. Consider a scenario where a customer wants a bespoke sofa with specific dimensions and fabric choices. The digital twin would adjust the manufacturing plan to meet those needs, optimizing resources and production time.

Advancements in Data Analytics and AI

Data analytics and artificial intelligence (AI) are expected to play a pivotal role in enhancing the capabilities of digital twins. These technologies can extract valuable insights from vast amounts of data collected by digital twins, leading to improved decision-making and optimized production processes.

- Improved Predictions: Advanced algorithms can analyze historical data and predict future outcomes with greater accuracy, allowing for better forecasting of demand and resource allocation. This predictive capability can be further enhanced by incorporating real-time data from various sources, providing more precise and timely insights.

- Automated Optimization: AI can automate the optimization of production processes, adjusting parameters like machine speeds, material usage, and assembly sequences to maximize efficiency and minimize waste. This automation will likely result in significant improvements in production output and cost savings.

- Enhanced Decision Making: Digital twins combined with AI and advanced analytics can provide real-time insights into production performance, allowing for quick and informed decision-making. This capability can enable proactive responses to challenges and opportunities, ensuring optimal resource allocation and faster response times.

Impact of Emerging Technologies

The integration of emerging technologies, such as the Internet of Things (IoT) and 5G, will further revolutionize the implementation of digital twins in furniture production. These technologies will facilitate the seamless collection and exchange of data, enabling more comprehensive and real-time insights into the entire production process.

- Real-time Data Integration: The IoT will enable the seamless integration of real-time data from various sources, including production machines, sensors, and supply chain partners. This will provide a holistic view of the production process, enabling more accurate and responsive decision-making.

- Increased Connectivity: 5G networks will facilitate the rapid transmission of large amounts of data, supporting the real-time operation and analysis of digital twins. This will enable more dynamic and responsive production processes.

- Improved Collaboration: The combination of digital twins, IoT, and 5G will enhance collaboration among different stakeholders in the furniture production process, from design to manufacturing and distribution.

Potential Future Developments

The future of digital twins in furniture production holds significant potential for transformative changes. These developments will likely lead to more personalized, efficient, and sustainable furniture production processes.

- Hyper-Personalized Furniture: Digital twins will enable the creation of furniture tailored to individual customer preferences, preferences that will be accurately captured and integrated into the design process.

- Predictive Maintenance for the Entire Supply Chain: Digital twins will extend beyond the factory floor to encompass the entire supply chain, providing insights into potential disruptions and allowing for proactive measures.

- Autonomous Production: The use of AI and robotics, integrated with digital twins, will lead to more autonomous production processes, optimizing resource allocation and minimizing human intervention in certain tasks.

Outcome Summary

Source: oilandgasmiddleeast.com

In conclusion, Digital Twins Streamline Furniture Production Processes offer a paradigm shift in manufacturing. By integrating digital representations of physical processes, businesses can optimize operations, enhance quality, and foster a more agile and responsive production environment. The potential for increased efficiency, reduced waste, and improved collaboration among various stakeholders is significant. This technology is poised to redefine the future of furniture manufacturing, and this exploration provides a comprehensive understanding of its potential.

FAQs

What are the key benefits of using digital twins in furniture production beyond efficiency gains?

Beyond efficiency, digital twins enable better quality control through simulated testing, leading to fewer defects and improved customer satisfaction. They also facilitate better resource allocation, reducing material waste and optimizing production schedules. This translates to cost savings and enhanced profitability.

How does data integration contribute to the accuracy of digital twin models?

Accurate and consistent data input from various sources like CAD designs, machine sensors, and production logs is crucial. Data integration ensures that the digital twin reflects the real-world processes with precision, allowing for reliable simulations and predictions.

What are the potential challenges in implementing digital twins in furniture production?

Challenges include the initial investment in software and hardware, the need for skilled personnel to manage and maintain the digital twin, and the potential for data silos to hinder integration. Careful planning and a phased implementation strategy are essential for mitigating these risks.

What are some examples of how digital twins can personalize the design process?

Digital twins can simulate personalized design requests, enabling manufacturers to virtually produce customized furniture pieces according to individual specifications, thus meeting the unique needs of customers. The ability to test and visualize different design variations before physical production minimizes errors and streamlines the customization process.