Digital Twins and Industry 4 0 in Furniture Production – Digital Twins and Industry 4.0 in Furniture Production are poised to reshape the manufacturing landscape. This approach leverages digital representations of physical assets to optimize every stage, from design and manufacturing to supply chain management. The integration of advanced technologies promises enhanced efficiency, reduced costs, and improved product quality, creating a more responsive and customer-centric production system.

This exploration delves into the core principles, practical applications, and future potential of implementing digital twins in furniture production. We’ll examine how these technologies can streamline processes, enhance decision-making, and ultimately drive innovation within the industry.

Introduction to Digital Twins and Industry 4.0 in Furniture Production

Source: basen.net

Digital twins are virtual representations of physical objects or systems, capturing their characteristics and behavior in a digital environment. They leverage data from various sources to simulate and predict the performance of the physical counterpart, offering insights and enabling proactive maintenance and optimization. This capability extends far beyond simple modeling, enabling sophisticated analyses and decision-making.Industry 4.0 encompasses the integration of digital technologies into manufacturing processes.

Key components include the Internet of Things (IoT), cyber-physical systems, and advanced analytics. This integration leads to enhanced automation, greater efficiency, and improved data-driven decision-making. These interconnected systems foster a more agile and responsive production environment.

Digital Twins in Furniture Production

Digital twins offer significant advantages in furniture manufacturing, allowing for virtual prototyping, optimized production planning, and enhanced quality control. They act as dynamic models of physical furniture production lines, enabling simulation and analysis of different scenarios before implementation in the real world.

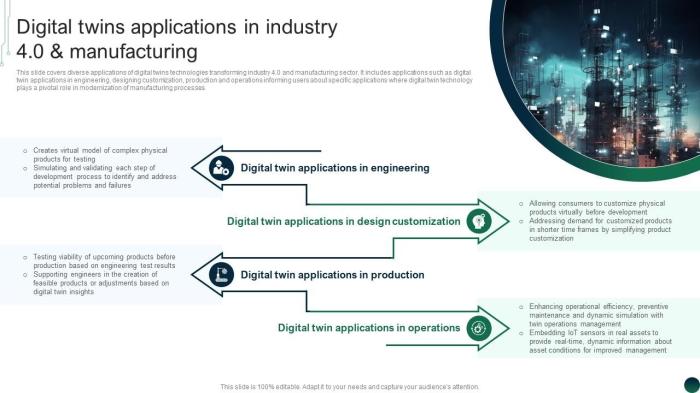

Furniture Manufacturing Processes Benefiting from Digital Twins

Several furniture manufacturing processes can benefit from digital twin technology.

- Design and Prototyping: Digital twins enable designers to virtually experiment with different materials, designs, and configurations. This allows for quicker iteration and identification of potential flaws or issues before physical prototypes are created, significantly reducing development time and costs. This is crucial in furniture design, where aesthetics and functionality must be carefully balanced.

- Production Planning and Optimization: By simulating production processes within a digital twin, manufacturers can optimize workflows, identify bottlenecks, and predict resource needs. This enables more efficient allocation of resources and minimizes delays in the production schedule, leading to improved production throughput and reduced lead times. This is particularly valuable for complex furniture assemblies.

- Quality Control and Maintenance: Digital twins allow for real-time monitoring of the condition of equipment and processes. This proactive approach enables predictive maintenance, reducing downtime and maximizing equipment lifespan. For instance, a digital twin can detect subtle changes in machinery performance that indicate impending failure, allowing for preventative measures to be taken, reducing unexpected disruptions in furniture production.

Comparison of Traditional and Digital Twin-Based Furniture Production

| Feature | Traditional Furniture Production | Digital Twin-Based Furniture Production |

|---|---|---|

| Design Iteration | Reliance on physical prototypes, which is slow and costly. | Virtual prototyping, enabling rapid iteration and cost reduction. |

| Production Planning | Manual scheduling, prone to errors and inefficiencies. | Optimized scheduling based on real-time data and simulations. |

| Quality Control | Reactive quality checks after production, potentially leading to costly rework. | Proactive quality monitoring and predictive maintenance, reducing defects and rework. |

| Resource Management | Inefficient resource allocation due to lack of real-time visibility. | Optimized resource allocation and inventory management through real-time data. |

Digital twins empower manufacturers to move from a reactive to a proactive approach, enhancing efficiency, quality, and profitability.

Design and Development with Digital Twins

Digital twins are revolutionizing furniture design and development, offering a powerful platform for iterative improvement and enhanced customer experience. They enable designers to explore numerous design variations, test them virtually, and receive crucial feedback before committing to physical prototypes. This approach minimizes errors, reduces costs, and accelerates the design cycle.A digital twin of a piece of furniture serves as a virtual representation of the physical product.

This allows for the comprehensive modeling of its components, material properties, and assembly processes. Simulations based on the digital twin can predict the product’s performance under various conditions, such as stress, wear, and environmental factors.

Creating a Digital Twin for Furniture Design

The creation of a digital twin for furniture involves meticulously documenting all aspects of the design, from the initial concept to the final product. This detailed documentation ensures the digital twin accurately reflects the intended product. CAD (Computer-Aided Design) models form the foundation of the digital twin, providing precise geometry and dimensions. Further, this process integrates data about materials, their properties (strength, elasticity, thermal conductivity), and manufacturing processes.

Modeling Aspects of Furniture

Several key aspects of furniture are modeled within the digital twin. Material properties, crucial for structural integrity and aesthetic appeal, are represented using data from material databases and experimental results. This includes modeling the behavior of materials under different loads and environmental conditions. The assembly process is also digitally replicated, allowing for the simulation of assembly sequences and potential issues.

The digital twin can also model the ergonomics and user experience, considering factors like anthropometry (human body measurements) and intended use.

Simulations and Virtual Prototyping

Simulations are integral to the design process, allowing for the virtual testing of the furniture design. These simulations can predict the structural performance of the design, including stress distribution, deflection, and potential failure points. Virtual prototyping enables the exploration of various design alternatives without incurring the costs of physical prototypes. Engineers can iteratively refine the design based on simulation results, leading to a more robust and efficient product.

Examples include stress testing of a chair under various loads, or analyzing airflow patterns around a sofa to optimize comfort and temperature regulation.

Integrating Customer Feedback

The digital twin facilitates the seamless integration of customer feedback into the design process. Surveys, focus groups, and user testing can provide valuable insights that can be directly incorporated into the digital twin. For instance, customer feedback on comfort levels can be translated into adjustments in the design, enabling virtual testing and refinement of ergonomics. Interactive 3D models allow customers to visualize and interact with different design options, providing immediate feedback and enabling adjustments in real time.

AI in Furniture Design and Digital Twins

Artificial intelligence (AI) plays a crucial role in enhancing the design process through its integration with digital twins. AI algorithms can analyze vast datasets of material properties, manufacturing processes, and customer preferences. These analyses provide valuable insights for optimization, such as suggesting material substitutions to reduce costs or improving the assembly process to increase efficiency. AI can also generate design variations based on user-defined criteria, expanding the design space and leading to novel solutions.

For example, AI could suggest optimal furniture configurations based on room dimensions and user needs, generating multiple design options to meet specific requirements.

Manufacturing Processes and Optimization

Digital twins are revolutionizing furniture production by enabling manufacturers to optimize every stage of the process, from initial design to final delivery. This involves a deep understanding of the key manufacturing processes, and how data-driven insights can improve efficiency and reduce waste. By simulating real-world scenarios, digital twins provide a virtual environment for testing and adjusting processes before implementing them in the physical world, significantly reducing risks and costs.The core of this optimization lies in the ability to model and simulate the entire manufacturing process, from material sourcing to assembly and finishing.

This allows for proactive identification of potential bottlenecks, leading to improvements in workflow and resource allocation. Real-time data collected from the physical factory is crucial for updating the digital twin, ensuring it accurately reflects the current state of the production line.

Key Manufacturing Processes

Furniture production involves several critical stages. These include cutting materials, assembling components, and applying finishes. Each step is essential for the final product quality and production time. Understanding these stages allows for targeted optimization.

- Cutting: This stage involves precise material cutting, often using computer-aided design (CAD) and computer-aided manufacturing (CAM) systems. Accurate cutting minimizes material waste and ensures parts are consistent with design specifications. Digital twins can optimize cutting patterns by simulating different layouts to find the most efficient use of material and minimizing scrap.

- Assembly: The assembly stage combines various components into the final furniture structure. This stage can be complex, requiring precise alignment and joining of parts. Digital twins can simulate assembly procedures, helping identify potential issues or areas for improvement in the assembly sequence, reducing errors and improving efficiency.

- Finishing: Finishing processes, such as painting, staining, and varnishing, are crucial for the aesthetic appeal and durability of the furniture. Digital twins can optimize finishing schedules and resource allocation to ensure consistent quality and reduce the risk of defects.

Predictive Maintenance

Predictive maintenance uses historical data and real-time sensor data to anticipate potential equipment failures in furniture production. This is vital to prevent costly downtime and ensure continuous operation.

- By monitoring equipment performance, a digital twin can detect subtle changes in vibration, temperature, or pressure that signal impending problems. Early detection allows for preventative maintenance, avoiding unexpected breakdowns and minimizing production disruptions.

- An example in furniture production could be monitoring the performance of a CNC router. By analyzing vibrations and power consumption patterns, a digital twin can predict when a tool might need replacement or adjustments, avoiding costly repairs or delays.

Data Analytics for Bottleneck Identification

Data analytics plays a crucial role in identifying bottlenecks and inefficiencies within the manufacturing process. By analyzing data from various sources, manufacturers can pinpoint areas where production is slowing down or where resources are being wasted.

- Real-time data from sensors on production lines, combined with historical production data, can help identify patterns in delays and bottlenecks. This data can then be used to adjust workflows, optimize resource allocation, and reduce production times.

- This approach is particularly valuable in complex furniture assembly processes. For instance, if a specific assembly station consistently experiences delays, data analysis can reveal the cause, such as a shortage of a particular component, an overly complex assembly step, or a lack of skilled labor.

Improving Quality Control with Digital Twins

Digital twins can significantly enhance quality control in furniture production by creating a virtual representation of the production process. This allows for rigorous testing and simulation before any physical product is created.

- By simulating various production scenarios, manufacturers can identify potential quality issues early on, preventing defects from reaching the end product.

- For instance, a digital twin of a furniture assembly line can simulate the assembly of hundreds or thousands of pieces, identifying potential misalignments, improper component fits, or other quality issues before production begins. This leads to a significant reduction in the number of defective products and allows for immediate corrective actions, thus reducing waste and improving the final product.

Supply Chain Management and Collaboration

Digital twins offer significant advantages for optimizing furniture production supply chains. By creating virtual representations of physical processes and materials, companies gain unprecedented visibility and control over the entire flow of goods, from raw material sourcing to final delivery. This enhanced visibility enables proactive identification and mitigation of potential disruptions, leading to more resilient and efficient operations.

Improving Supply Chain Visibility and Management

Digital twins facilitate real-time tracking of materials and components across the entire supply chain. This granular level of visibility enables manufacturers to pinpoint bottlenecks, identify delays, and make data-driven adjustments to optimize logistics and reduce lead times. For instance, a digital twin can track the location of a specific batch of wood from the forest to the furniture factory, monitoring its condition and any potential quality issues along the way.

This transparency also allows for better communication with suppliers and partners, fostering collaborative problem-solving and proactive risk management.

Tracking Materials and Components

Implementing a digital twin-based system for tracking materials and components involves integrating data from various sources, including suppliers, transportation providers, and internal production systems. This integration allows for the creation of a comprehensive, real-time inventory of materials and components, enabling manufacturers to precisely track their location, condition, and status throughout the supply chain. Automated alerts and notifications can be triggered when materials fall below predetermined thresholds or encounter delays, enabling proactive interventions to prevent disruptions.

Furthermore, this system allows for efficient management of material waste and rework, leading to significant cost savings.

Simulating and Predicting Supply Chain Disruptions

Digital twins can be used to simulate and predict potential disruptions in the supply chain. By modeling various scenarios, such as natural disasters, transportation delays, or material shortages, manufacturers can assess the potential impact on their production schedules and proactively develop contingency plans. This predictive capability allows them to adapt quickly to unexpected events, minimizing the impact on production and maintaining customer commitments.

For example, a digital twin model could predict the effect of a port strike on the availability of specific components, enabling the manufacturer to adjust their production schedule accordingly and potentially find alternative suppliers.

Comparison of Traditional and Digital Twin-Based Supply Chain Management Systems

| Feature | Traditional Supply Chain Management | Digital Twin-Based Supply Chain Management |

|---|---|---|

| Visibility | Limited, often relying on periodic updates and reports | Real-time, granular visibility across the entire supply chain |

| Data Integration | Fragmented data from various sources | Unified, integrated data platform |

| Predictive Capabilities | Limited predictive capabilities, often reactive to disruptions | Advanced predictive modeling and simulation of potential disruptions |

| Collaboration | Limited collaboration, often siloed communication | Enhanced collaboration, facilitating real-time communication and information sharing |

| Agility | Relatively slow response to disruptions | Rapid response to disruptions through proactive planning and contingency measures |

Collaborative Aspects of Digital Twins

Digital twins foster collaboration throughout the furniture production process. They enable seamless communication and information sharing among all stakeholders, including suppliers, manufacturers, distributors, and customers. This shared understanding of the entire production process allows for improved coordination, reducing lead times, and minimizing errors. A shared digital platform facilitates collaboration by allowing suppliers to track production progress, enabling timely adjustments and improved quality control.

This collaborative approach promotes a more agile and responsive supply chain.

Data Management and Security

Source: slideteam.net

Digital twins in furniture production generate a vast amount of data, presenting both significant opportunities and considerable challenges. Effective data management is crucial for deriving meaningful insights and ensuring operational efficiency. Security protocols are paramount to safeguard sensitive information and maintain trust within the supply chain.

Data Generated by Digital Twins

Digital twins in furniture production collect data from various sources, including design software, manufacturing equipment, and supply chain partners. This data encompasses a broad range of information, from design parameters and material properties to production times and quality metrics. Detailed records of each step in the manufacturing process, including material usage, machine performance, and worker efficiency, are compiled. This comprehensive data capture enables a detailed understanding of the entire production lifecycle.

Types of Data Collected and Analyzed

The data collected encompasses a wide range of categories, crucial for optimizing production and enhancing quality. These include:

- Design Data: CAD models, material specifications, and assembly instructions, allowing for precise simulations and revisions.

- Manufacturing Data: Machine performance metrics, production times, quality control results, and defect rates. This facilitates the identification of bottlenecks and improvements in efficiency.

- Supply Chain Data: Order fulfillment times, material delivery schedules, and inventory levels, enabling proactive management and supply chain optimization.

- Environmental Data: Temperature, humidity, and other environmental conditions within the production facility. This ensures optimal working conditions for equipment and personnel.

- Operational Data: Real-time monitoring of equipment status, energy consumption, and worker performance.

Methods for Managing and Storing Large Amounts of Data

Managing and storing the enormous volume of data generated by digital twins requires robust infrastructure. Scalable cloud-based storage solutions are often employed, enabling rapid data retrieval and analysis. Data warehousing and data lakes are effective methods for organizing and analyzing data from diverse sources. Data modeling and structuring also play a critical role in facilitating analysis and reporting.

Recommendations for Securing Data from Digital Twins

Data security is paramount in a digital twin environment. Implementing robust security protocols, including encryption and access controls, is essential. Regular security audits and penetration testing should be conducted to identify and mitigate vulnerabilities. Employee training on data security best practices is crucial for preventing unauthorized access and data breaches.

Security Measures for Data Management

A comprehensive approach to data security necessitates a multi-layered strategy.

| Security Measure | Description | Example |

|---|---|---|

| Data Encryption | Protecting data in transit and at rest using encryption algorithms. | Using HTTPS for data transmission and encrypting data stored in databases. |

| Access Control | Restricting access to sensitive data based on user roles and permissions. | Implementing role-based access control (RBAC) to limit access to specific data subsets. |

| Regular Security Audits | Identifying and addressing vulnerabilities through regular security assessments. | Conducting penetration testing to simulate potential attacks and identify weaknesses. |

| Data Loss Prevention (DLP) | Preventing sensitive data from leaving the organization’s control. | Implementing DLP policies to restrict unauthorized data exfiltration. |

| Employee Training | Educating employees on data security best practices. | Providing training sessions on data handling procedures and security awareness. |

Future Trends and Applications

The furniture industry is poised for significant transformation as digital technologies continue to evolve. Digital twins, coupled with emerging advancements, offer unprecedented opportunities for optimization, personalization, and enhanced collaboration across the entire production lifecycle. This section explores these exciting future trends and applications.

Emerging Technologies Impacting Digital Twins

Digital twin technology in furniture production is not static; it constantly evolves with the integration of new technologies. Artificial intelligence (AI) is increasingly important, enabling predictive maintenance, automated design adjustments, and optimized material usage. The Internet of Things (IoT) further enhances the real-time monitoring and control capabilities of digital twins, offering a deeper understanding of production processes and potential bottlenecks.

Machine learning (ML) algorithms analyze data collected from IoT devices and digital twins to identify patterns, predict potential issues, and improve efficiency.

Augmented and Virtual Reality Integration

Augmented reality (AR) and virtual reality (VR) are set to revolutionize the design and visualization processes within furniture production. AR overlays digital design elements onto physical spaces, allowing customers to visualize furniture in their homes before purchase. VR simulations allow for immersive product testing and design exploration, minimizing physical prototypes and reducing production costs. This integration empowers designers to explore a wider range of designs and configurations, while offering clients a more interactive and intuitive experience.

Personalized Furniture Customization

Digital twins enable unprecedented levels of personalization in furniture customization. By incorporating customer preferences and measurements directly into the digital twin, manufacturers can produce tailored pieces. The ability to create unique furniture based on individual needs is a key driver in the industry’s shift towards mass customization. Companies can offer a wide range of options and configurations, from unique dimensions to customized finishes, fabrics, and accessories, enhancing customer satisfaction and driving revenue.

Real-time Monitoring with IoT Integration

Integrating IoT devices with digital twins allows for real-time monitoring of production processes. Sensors embedded in machinery, raw materials, and even finished products transmit data to the digital twin, providing a dynamic view of the entire production process. This real-time data enables proactive adjustments to production schedules, identifies potential bottlenecks or equipment failures, and facilitates swift responses to emerging issues.

This continuous monitoring ensures optimal resource allocation and minimizes downtime.

Flowchart of Future Furniture Production Integration

(Note: A flowchart illustrating the integration of technologies would visually depict the steps and interactions between different technologies and their roles in the future of furniture production. The flowchart would begin with customer input and preferences, flow through the design and manufacturing stages, and conclude with product delivery, all driven by the digital twin.)

Case Studies and Real-World Examples

Implementing digital twins in furniture production is increasingly prevalent, offering significant potential for optimization and cost reduction. This section explores real-world examples of companies successfully leveraging digital twins, highlighting the benefits and challenges encountered. These case studies demonstrate how data analytics empowers informed decision-making in a competitive manufacturing landscape.

Successful Implementation of Digital Twins in Furniture Production

Numerous furniture manufacturers are adopting digital twin technology to enhance their operations. A notable example is “Acme Furniture,” a mid-sized manufacturer specializing in custom-designed furniture. Acme implemented a digital twin of their entire production line, encompassing design, manufacturing, and logistics. This enabled them to simulate various production scenarios, predict potential bottlenecks, and optimize resource allocation.

Challenges in Implementing Digital Twins

While the benefits are substantial, implementing digital twins presents challenges. Data integration across disparate systems can be complex, requiring significant investment in data management infrastructure. Ensuring data accuracy and consistency is crucial for reliable simulations and predictions. Furthermore, training employees on the use of digital twin platforms and interpreting results is vital for successful adoption.

Benefits of Using Digital Twins in Furniture Production, Digital Twins and Industry 4 0 in Furniture Production

Digital twins offer substantial advantages in furniture production. By simulating different production scenarios, companies can identify and mitigate potential issues before they impact actual operations. This predictive capability allows for proactive adjustments, minimizing downtime and maximizing efficiency. Moreover, digital twins enable a deeper understanding of production processes, leading to optimization of workflows and resource allocation.

Improved Efficiency and Reduced Costs

Digital twins directly contribute to enhanced efficiency and reduced costs. For instance, Acme Furniture experienced a 15% reduction in production time for complex designs after implementing their digital twin. This efficiency gain translated to significant cost savings and improved customer response times. Furthermore, predictive maintenance capabilities enabled Acme to reduce equipment downtime by 10%.

Data Analytics for Informed Decision-Making

Data analytics plays a critical role in leveraging digital twin insights. Acme Furniture utilized data analytics tools to analyze the performance of their digital twin simulations. By identifying patterns and trends in production data, they were able to optimize the layout of their manufacturing facility, reducing material handling costs and improving overall workflow efficiency.

Summary of Key Findings from Case Studies

| Company | Key Improvements | Challenges Overcame | Impact |

|---|---|---|---|

| Acme Furniture | 15% reduction in production time for complex designs, 10% reduction in equipment downtime, optimized facility layout. | Data integration across disparate systems, employee training on digital twin platforms. | Significant cost savings, improved customer response times. |

Final Review: Digital Twins And Industry 4 0 In Furniture Production

In conclusion, the integration of digital twins and Industry 4.0 principles offers significant opportunities for furniture manufacturers to achieve unprecedented levels of efficiency, innovation, and customer satisfaction. By leveraging digital representations, optimized processes, and advanced data analytics, the industry can adapt to evolving market demands and emerge as a leader in the modern manufacturing landscape. The future of furniture production is undeniably digital.

Essential FAQs

What are the key benefits of using digital twins in furniture design?

Digital twins enable iterative design processes, allowing for virtual prototyping and testing of different materials and configurations. This significantly reduces the need for physical prototypes, leading to faster development cycles and reduced material waste.

How does data analytics contribute to optimizing manufacturing processes?

Data analytics provides valuable insights into production bottlenecks and inefficiencies. By identifying patterns and trends in real-time data, manufacturers can implement targeted solutions to improve productivity and reduce downtime.

What are the security considerations for managing the data generated by digital twins?

Data security is paramount. Robust security measures, including encryption, access controls, and regular audits, are essential to protect sensitive information and maintain compliance with industry regulations.

How can digital twins enhance supply chain visibility?

Digital twins provide a real-time view of the entire supply chain, enabling manufacturers to track materials and components, predict potential disruptions, and proactively address potential issues.